Audi Q7: General, Technical data

Identification

Engine Number/Engine Specifications

Engine Number

Note

Note

The engine number can only be seen with the engine cover removed.

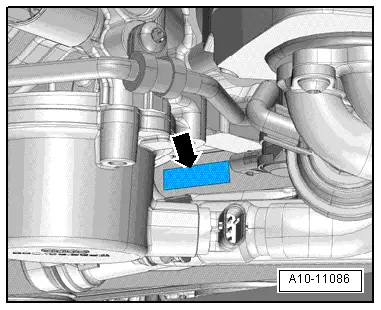

- The engine number ("engine code" and "serial number") is located on the front of the cylinder block at the top -arrow-.

- Engine codes beginning with "C" are four letters long.

- The first three positions of the engine code stand for displacement and the mechanical engine structure. They are stamped in the cylinder block, including the serial number.

- The fourth position represents the engine output and torque and is dependent on the engine control module.

- Refer to the Maintenance Tables for the allocations of the engine codes.

Note

Note

- The four digit engine code is on the type plate (market-specific), vehicle data label and engine control module.

- Component locations of the type plate (market-specific) and vehicle data label.

Safety Precautions

Safety Precautions when Working on Fuel Supply System

There Is a Risk of Injury Because the Fuel Is under Pressure.

The fuel system is under pressure. Injuries are possible from fuel spraying out.

Before opening the fuel system:

- Wear protective eyewear.

- Wear safety gloves.

- Reduce the pressure: place clean cloths around the connection point and carefully open the connection point.

Risk of a Fire Due to Leaking Fuel.

When the battery is connected, the door contact switch activates the fuel pump when opening the driver door. Leaking fuel can ignite and start a fire.

- Before opening the fuel system, short circuit the fuel pump power supply.

Safety Precautions when Working on Vehicles with Start/Stop System

There Is a Risk of Injury Due to the Engine Starting Unexpectedly.

The engine can start unexpectedly on vehicles with an activated Start/Stop System. A message in the instrument cluster indicates whether the Start/Stop System is activated.

- Deactivating the Start/Stop System: Switch off the ignition.

Safety Precautions during Road Test with Testing Equipment

There Is a Risk of Injury Caused by Unsecured Testing Equipment.

If the front passenger airbag deploys during an accident, unsecured testing equipment becomes a dangerous projectile.

- Secure the testing equipment on the rear seat.

or

- Have a second person operate the testing equipment on the rear seat.

Safety Precautions when Working on Cooling System

Risk of Scalding Due to Hot Coolant

The cooling system is under pressure when the engine is warm. Risk of scalding due to hot steam and hot coolant.

- Wear safety gloves.

- Wear protective eyewear.

- Reduce the pressure by covering the coolant expansion tank cap with a cloth and carefully opening it.

Safety Precautions when Working on Ignition System

Risk of Injury Due to Electrocution

When the engine is running the ignition system is under high-voltage. It is possible to be electrocuted by touching the ignition system.

- Never touch or remove the ignition wires when the engine is running or at starting speed.

Risk of Damaging the Components.

Washing the engine as well as connecting and disconnecting wires when the engine is running can damage components.

- Switch off the ignition before connecting and disconnecting wires.

- Switch off the ignition before washing the engine.

Safety Precautions when Working on Exhaust System

Note the following When Working on the Exhaust System:

Caution

Caution

Risk of damaging the coupling.

- Coupling must not be bent more than 10º.

- Do not load the coupling on the cable.

- Do not damage the wire mesh on the coupling.

Safety Precautions when Working on Subframe

Note the following When Working on the Subframe:

Caution

Caution

There is a risk of damaging the suspension components.

- If the subframe mount, steering gear or subframe crossbrace are not installed correctly, do not rest the vehicle on its wheels.

- Supporting the vehicle at the subframe or the subframe crossbrace (for example, using a floor jack or similar device) is not permitted.

Repair Information

Guidelines for Clean Working Conditions

Note

Note

Even small pieces of debris can cause faults. Observe the following guidelines for cleanliness when working on the fuel supply system, injection system and turbocharging system:

- Before loosening, thoroughly clean the connection points and surrounding areas with engine or brake cleaner, and then allow the cleaned area to dry completely.

- Immediately seal off any open lines and connections with clean plugs, for example, taken from the Engine Bung Set -VAS6122-.

- Place the removed parts on a clean surface and cover them. Only use lint-free cloths.

- Carefully cover or seal opened components if repairs are not performed immediately.

- Only install clean parts: remove the replacement parts from their packaging just before installing them. Do not use parts that have been stored outside of their packaging (for example, in tool boxes etc.).

- Do not work with compressed air when the system is open. Do not move the vehicle if at all possible.

- Make sure no fuel gets onto the fuel hoses. If necessary, the fuel hoses must be cleaned again immediately.

- Protect any disconnected connectors from dirt and moisture, and only connect them when they are completely dry.

Foreign Objects in Engine

- To prevent foreign objects from entering when working on the engine, open intake and exhaust tract channels must always be sealed off with suitable plugs, for example from the Engine Bung Set -VAS6122-.

- If mechanical damage to a cylinder bank is found, check the intake and exhaust tract and the combustion chambers in the opposite cylinder bank for foreign objects to prevent subsequent damage.

Contact Corrosion

Contact corrosion can occur if incorrect fasteners (bolts, nuts, washers, etc.) are used.

For this reason, only fasteners with a special surface coating are installed.

In addition, rubber or plastic parts and adhesives consist of non-conductive materials.

If there are doubts about whether parts can be used or not, then use new parts. Refer to the Parts Catalog.

Note

Note

- Only original replacement parts are recommended. They are checked and compatible with aluminum.

- The use of Audi accessories is recommended.

- Contact corrosion damage is not covered under warranty.

Line Routing and Securing

- Mark the individual fuel, hydraulic and vacuum lines, EVAP system as well as the wires before removing them. This will prevent interchanging them and will ensure the original installation position. Draw sketches or take pictures of them if required.

- Due to the limited space inside the engine compartment, allow sufficient clearance to all moving or hot parts to avoid damaging the lines.

Radiator and Condenser Assembly

The radiator and condenser may have small indentations on the fins even when installed correctly. This is not damage. Radiators or condensers should not be replaced because of slight impressions like these.