Audi Q7: Camshaft, Measuring Axial Clearance

Special tools and workshop equipment required

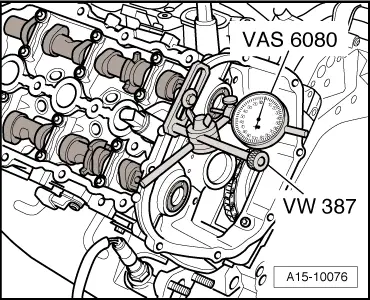

- Dial Gauge Holder -VW387-

- Dial Gauge - 0-3mm -VAS6080-

Procedure

- Remove the camshafts. Refer to → Chapter "Camshaft, Removing and Installing".

- Mark the allocation of the roller rocker lever for installation later.

- Remove the roller rocker lever and place it on a clean surface.

- Reinstall the camshafts and the guide frame. Refer to → Fig. "Guide Frame for the Camshaft Cylinder Head Bank 1 (Right) - Tightening Specification and Sequence" or → Fig. "Guide Frame for the Camshaft Cylinder Head Bank 2 (Left) - Tightening Specification and Sequence" and tighten the old bolts to 8 Nm without an additional turn.

- Secure the Dial Gauge Holder -VW387- with the Dial Gauge - 0-10mm -VAS6079- on the cylinder head as shown.

- Press the camshaft against the dial gauge by hand.

- Set the dial gauge to "0".

- Press the camshaft off of the dial gauge and read the value.

- Axial play: 0.100 to 0.191 mm.

Camshaft, Measuring Radial Clearance

Special tools and workshop equipment required

- Plastigage

Procedure

Note

Note

Use old bolts to measure radial clearance measurement.

- Remove the camshafts. Refer to → Chapter "Camshaft, Removing and Installing".

- Mark the allocation of the roller rocker lever for installation later.

- Remove the roller rocker lever and place it on a clean surface.

- Clean the bearing and the bearing journals.

- Place the Plastigage over entire width of bearing journal or into the bearing.

- The Plastigage must rest in center of bearing.

- Install the camshafts, mount the guide frame and tighten the old bolts. Refer to → Fig. "Guide Frame for the Camshaft Cylinder Head Bank 1 (Right) - Tightening Specification and Sequence" or → Fig. "Guide Frame for the Camshaft Cylinder Head Bank 2 (Left) - Tightening Specification and Sequence". When doing this, be careful not to rotate the camshafts.

- Remove the bearing bracket and camshafts.

- Compare the width of the Plastigage with the measuring scale.

Radial clearance:

- For 24 mm bearing diameter: 0.024 to 0.066 mm

- For 36 mm bearing diameter: 0.032 to 0.078 mm

- Replace the bolts for the final assembly.

Camshaft, Removing and Installing

Special tools and workshop equipment required

- Impact Puller -T10133/3- from Injector/Combustion Chamber Seal Tool Set -T10133C-

- Locating Pins -T40116-

- Hand Drill with Plastic Brush Attachment

- Protective Eyewear

- Sealant. Refer to the Parts Catalog.

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- Bolts - Guide frame(s)

- O-ring - Camshaft adjustment valve(s)

Removing

- Remove the camshaft timing chains from the camshafts. Refer to → Chapter "Camshaft Timing Chain, Removing from Camshafts".

Cylinder Bank 1 (Right):

- Remove the high pressure pump. Refer to → Chapter "High Pressure Pump, Removing and Installing".

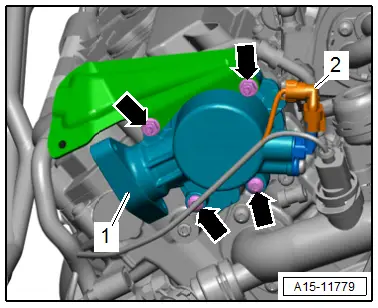

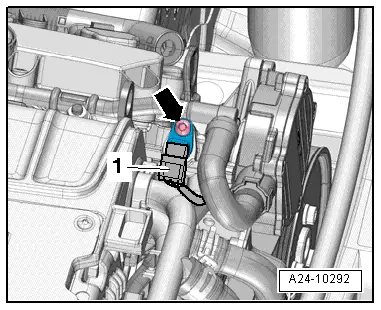

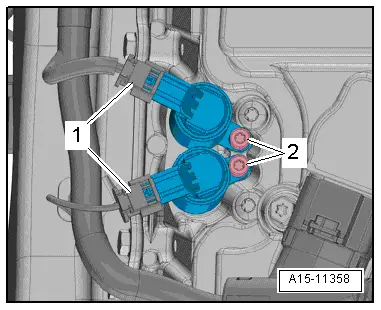

- Disconnect the connector -2- on the Camshaft Position Sensor -G40-.

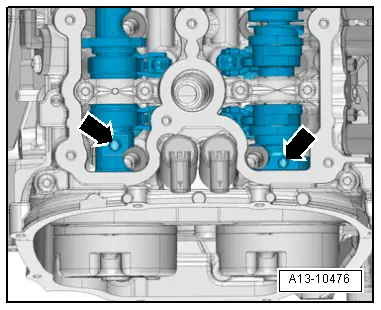

- Remove the bolts -arrows- and the high pressure pump housing -1-.

- Remove the bolt -arrow- for the ground wire.

- Move the electrical wiring harness to the side.

Cylinder Bank 2 (Left):

- Remove the vacuum pump. Refer to → Brake System; Rep. Gr.47; Vacuum System; Vacuum Pump, Removing and Installing.

- Disconnect the connector -1- for the Camshaft Position Sensor 2 -G163-.

Note

Note

Ignore the -arrow-.

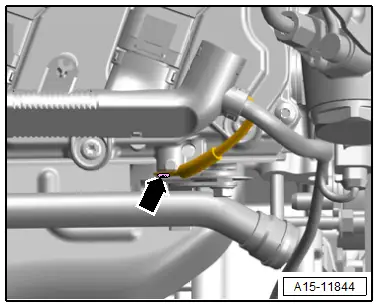

- Remove the bolt -arrow- for the ground wire.

- Move the electrical wiring harness to the side.

Continuation for Both Sides:

- Remove the respective intake manifold lower section. Refer to → Chapter "Intake Manifold Lower Section with Fuel Rail, Removing and Installing".

- Remove the bolts -arrows- and the corresponding camshaft adjuster valves.

Cylinder Bank 1 (Right):

Note

Note

For better accessibility loosen the high pressure line on the fuel rail and on the bracket. Leave the high pressure line in the installation position.

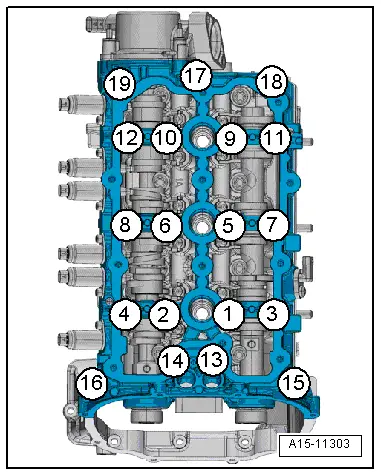

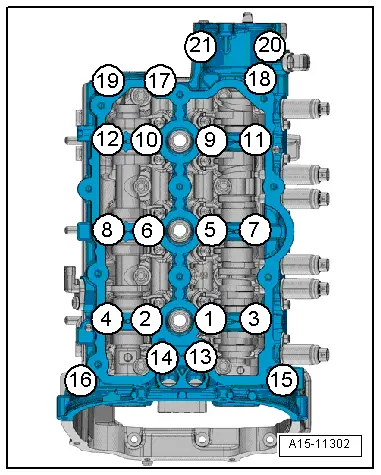

- Loosen the guide frame bolts in the following sequence: -19 to 1-.

- Remove the bolts, carefully loosen the guide from out of the bond and place it with the camshafts on a soft surface.

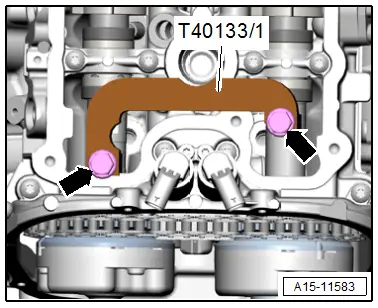

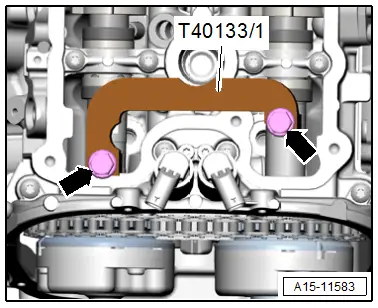

- Remove the Camshaft Clamp -T40133/1--arrows-.

- Mark the camshafts, remove them and lay them on a clean surface.

Cylinder Bank 2 (Left):

- Loosen the guide frame bolts in the following sequence: -21 through 1-.

- Remove the bolts, carefully loosen the guide from out of the bond and place it with the camshafts on a soft surface.

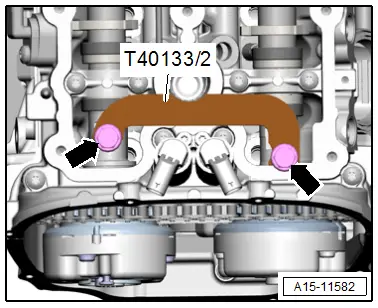

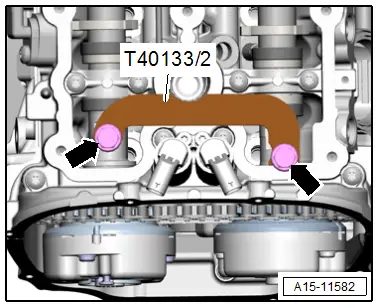

- Remove the Camshaft Clamp -T40133/2--arrows-.

Installing

Note

Note

Replace the seals and plugs after removal.

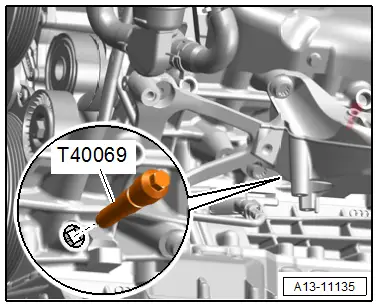

- Secure crankshaft in "TDC" position using Crankshaft Locking Pin -T40069-.

- The hydraulic lifters and roller rocker lever are inserted.

Caution

Caution

Risk of contaminating the lubricating system and the bearing.

Cover open engine components.

WARNING

WARNING

Risk of eye injury.

Wear protective eyewear!

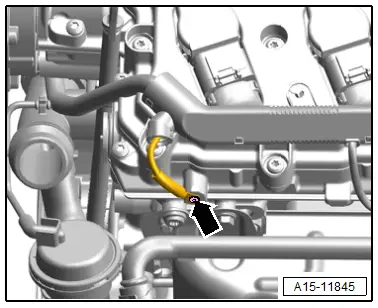

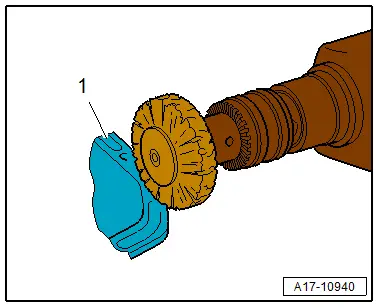

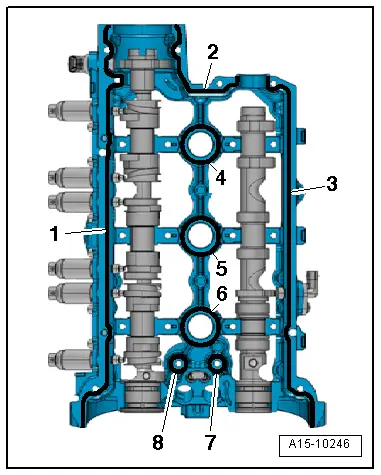

- Remove any sealant residue on the cylinder head and the guide frame -1- using a rotating plastic brush.

- Clean any oil or grease off the sealing surfaces.

- Oil the camshaft running surfaces.

- Insert the camshafts in the guide frame.

- The placement of the camshafts must be exactly within the axial bearings -arrows- of the guide frame.

- The compression ring ends -1, 2 and 3- must face up or down. They must never face sideways.

Note

Note

Depending on the version on the exhaust camshaft one or two compression rings -2 or 3- are installed. Refer to the Parts Catalog for the allocation.

- Rotate the guide frame with the camshafts inserted while holding them securely in the frame.

- Rotate the camshafts until the threaded holes -arrows- face upward.

- Check if the camshafts still lie in the guide frame axial bearings.

Cylinder Bank 1 (Right):

- Install the Camshaft Clamp -T40133- on cylinder head -arrows- and tighten to 25 Nm.

Cylinder Bank 2 (Left):

- Install the Camshaft Clamp 2 -T40133/2- on cylinder head -arrows- and tighten to 25 Nm.

Continuation for Both Cylinder Banks:

Note

Note

Note the expiration date for the sealant.

- Cut the tube nozzle at the front marking (nozzle diameter: about 2 mm).

- Rotate the guide frame again.

Caution

Caution

Risk of contaminating camshaft bearing with excess sealant.

Do not apply sealant beads thicker than indicated.

- Apply sealant beads -4 through 8- to the clean sealing surfaces on the guide frame as shown in the illustration.

- Sealant bead thickness, 2.0 mm.

- Apply sealant beads -1 through 3- to the clean sealing surfaces on the guide frame as shown in the illustration.

- Sealant bead thickness: 2.5 mm.

Note

Note

The guide frame must be installed within five minutes after applying the sealant.

- Place the guide frame on the cylinder head.

- Install the Locating Pins -T40116- into the guide frame and cylinder head.

- Tighten the camshaft guide frame bolts.

Note

Note

After installing the guide frame, let the sealant harden for approximately 30 minutes.

- Clean the external sealing head holes in the left and right cylinder heads of oil and grease.

- Coat the outer edge of the sealing plug -arrow- with sealant. Refer to Parts Catalog.

- Drive in the sealing plugs until they are flush.

- Remove the Locating Pins -T40116- with the Injector/Combustion Chamber Seal Tool Set - Impact Puller -T10133/3-.

Installation is performed in reverse order of removal, while noting the following:

- Install the camshaft adjustment valves. Refer to → Chapter "Overview - Cylinder Head".

- Install the intake manifold lower section. Refer to → Chapter "Intake Manifold Lower Section with Fuel Rail, Removing and Installing".

- Install the high pressure pump motor housing and the high pressure pump. Refer to → Chapter "High Pressure Pump, Removing and Installing".

- Install the vacuum pump. Refer to → Brake System; Rep. Gr.47; Vacuum System; Vacuum Pump, Removing and Installing.

- Connections and wire routing. Refer to → Wiring diagrams, Troubleshooting & Component locations.

- Position the camshaft timing chains on the camshafts. Refer to → Chapter "Camshaft Timing Chain, Removing and Installing".

Caution

Caution

Risk of damaging the valves and piston crowns after working on valvetrain.

- The motor must not be started for about 30 minutes after installing camshafts because the hydraulic lifters must seat themselves.

- To ensure valves do not strike pistons when starting, carefully rotate the engine at least two full revolutions.

Tightening Specifications

- Refer to → Chapter "Overview - Valvetrain"

- Refer to → Fig. "Guide Frame for the Camshaft Cylinder Head Bank 1 (Right) - Tightening Specification and Sequence"

- Refer to → Fig. "Guide Frame for the Camshaft Cylinder Head Bank 2 (Left) - Tightening Specification and Sequence"

Camshaft Adjuster Valves, Removing and Installing

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- O-ring - Camshaft adjuster valve(s)

Removing

- Disconnect the connector -1-.

- Remove the bolt -2- in question and then remove the valve:

Installing

Install in reverse order of removal and note the following:

Note

Note

- Replace the O-rings after removing them.

- Secure all hose connections with hose clamps that match the ones used in series production. Refer to the Parts Catalog.

Tightening Specifications

- Refer to → Chapter "Overview - Valvetrain"

Hydraulic Lifter, Checking

Note

Note

- The hydraulic lifter cannot be repaired.

- Irregular valve noises are normal while starting the engine.

Special tools and workshop equipment required

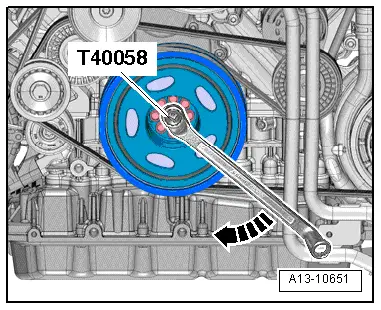

- Crankshaft Socket -T40058-

- Feeler Gauge

Procedure

- Start the engine and let it run until the radiator fan switches on once.

- Increase the engine speed for about two minutes to approximately 2500 RPM. Perform a road test if necessary.

- If the hydraulic lifters are still loud, determine which lifter is faulty as follows:

- Remove the cylinder head cover. Refer to → Chapter "Cylinder Head Cover, Removing and Installing".

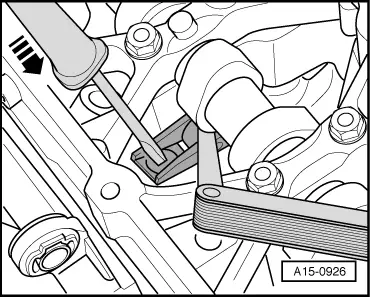

- Rotate the crankshaft in direction of engine rotation in direction of -arrow- using the Crankshaft Socket -T40058- and offset open-end wrench.

- To determine the play between cam lobes and roller rocker lever, press the lever down in direction of -arrow-.

- If a 0.20 mm feeler gauge can slide between the cam lobes and roller rocker lever, replace the hydraulic lifter. Refer to → Chapter "Camshaft, Removing and Installing".

Final Procedures

- Install the cylinder head cover. Refer to → Chapter "Cylinder Head Cover, Removing and Installing".