Audi Q7: Tire Wear and Service Life

General Information

Note

Note

- Having the correct air pressure in the tires can also decrease the amount of tire wear and increase the tire mileage.

- Always make sure that the tires are inflated to the correct air pressure.

Numerous demands are made on a tire.

Depending on the use of the tire and the vehicle type, certain demands may be more heavily weighted while others are accordingly less significant.

One expects greater adhesion, even on wet or flooded surfaces from H, V and Z tires for high-powered vehicles. Consequently, the service life for tires of this type is not as high as for S or T tires, for example.

High Speed Tires, Wear Characteristics

These tires are designed for the highest speeds. Good traction on wet roads is emphasized when developing these tires. Tread compounds do not have the abrasion resistance of tires for lower speeds, such as T and H tires.

Therefore the service life expectancy of high-speed tires is substantially lower under comparable operating conditions.

Tire, Uniformly Worn

The demands on the tires increase constantly.

The causes are the following factors:

- Higher vehicle weight

- High speeds

- Increased vehicle safety

A high load on tires naturally causes high wear.

The driving style has a profound influence on the tire wear. Therefore, for complaints about wear when the treads are uniformly worn, the tires will not be replaced under warranty.

The actual service life of a tire can only be determined when the tread depth is 2 mm, see diagram.

Tire Wear, One Sided

In many causes, this is caused by driving style, but sometimes it is also caused by incorrect axle adjustment.

One-sided wear, in conjunction with scrub marks on tread ribs and finer grooves, always appears when tires roll at an extreme slip angle and consequently scrub on the road surface.

Driving quickly around curves leads to increased wear, especially on the outside edge.

A rounded tire shoulder in conjunction with especially high wear on the outer tread bars indicates fast driving around curves. This wear pattern is influenced by the driving style.

The suspension is adjusted to certain toe and camber values to optimize handling. When tires roll under conditions other than those specified, increased and one-sided wear must be expected.

Strong one-sided wear can be caused especially by incorrect toe and camber values. This increases the danger of diagonal wear spots.

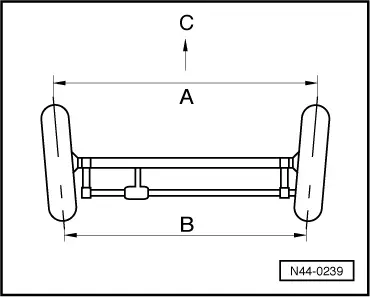

Toe-out or negative toe-in:

The distance between the fronts of the tires -A- is greater than the distance between the backs of the tires -B- (-C- = direction of travel).

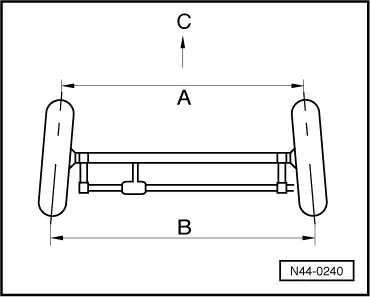

Toe-in or positive toe-in:

The distance between the fronts of the tires -A- is less than the distance between the backs of the tires -B- (-C- = direction of travel).

To avoid one-sided tire wear, ensure that the wheel alignment remains within the tolerances specified by the vehicle manufacturer. The most common deviation of wheel alignment is caused by external influences, for example hard contact with the curb when parking.

A measurement of the axle geometry can determine whether the wheel alignment is within the specified tolerances or whether a correction of the wheel alignment is necessary.

Acceptable Tread Depth Variance

Note

Note

Observe the acceptable vehicle tread variance in this chapter.

Wear on One Side, Faulty Adjustment

If the complaint is about one-sided tire wear, check the axle geometry. Billing to warranty is only possible in cases of one-sided tire wear that is caused by axle geometry errors that cannot be traced back to external effects on the tires and rims. The axle alignment log should be included with the tire complaint registration.

Due to tire skew, increased and one-sided wear. Frequently in conjunction with raised running surface to the point of ridge formation on tread edges.

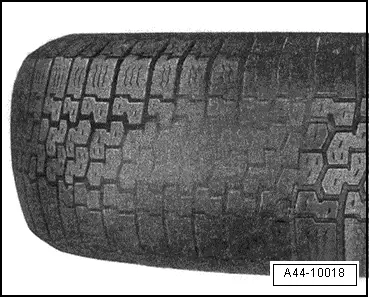

Tire Wear, Center

This wear pattern is found on drive wheels on high-powered vehicles that often drive long stretches at high speed.

At high speeds, the centrifugal force increases the tire diameter at the center of the tread more than at the shoulders of the tire. The drive forces from the center area of the tread are transferred to the road surface. This is reflected in the wear pattern.

These effects can appear especially extreme on wide tires.

Reducing the tire pressure is not an effective remedy for this wear pattern.

DANGER!

DANGER!

For safety reasons, tire pressure must never be lowered below specified pressure under any circumstances.

A largely even wear pattern can be achieved if tires are changed in a timely manner from the tractive to the non-tractive axle.

Typical wear pattern of tires on the tractive axle of high-powered vehicles. The increased wear at the tread center is caused by stresses related to the centrifugal force of the tire and the transmission of traction forces.

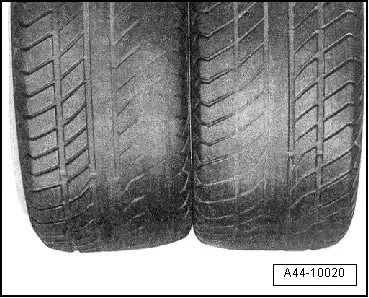

Diagonal Washouts

Diagonal wear spots run at an angle of approximately 45º with respect to the plane of circumference. They usually occur once, but may also occur several times along the tire circumference.

Wear spots appear almost exclusively on the non-tractive tires, especially the rear left tire. There are vehicle models where wear spots appear rounded, which are not a problem. The effect is increased by high toe values. Toe values at the lower tolerance limit of the specified value improve the wear pattern.

The tire component integration is often found in the area with the most pronounced diagonal wear spots.

Wheels with toe-in roll with a slip angle even when the vehicle is traveling straight ahead. This leads to diagonal tension in the contact zone between tires/road surface.

Driving with reduced tire pressure will improve the wear pattern. To prevent such wear patterns, the toe values of both rear wheels should be the same and the specified tire pressure should be maintained.

If wear spots are detected, mount the wheels on the tractive axle if the wear spots are still in the initial stage. Deeper wear spots are irreparable.

Wear Due to Faulty Adjustment

When a customer complains of diagonal wear spots, the toe adjustment must be checked. If it is OK, the cause for the diagonal wear spots is most likely in the tires. Billing to warranty is possible in this case.

The axle alignment log should be included with the tire complaint.

Tires with diagonal wear spots which developed due to faulty adjustment of the axle geometry are excluded from the warranty.