Audi Q7: Trailer Hitch

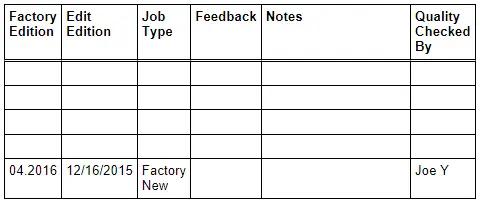

Component Location Overview - Trailer Hitch

1 - Towing Recognition Control Module -J345-

- Overview. Refer to → Chapter "Overview - Trailer Hitch".

- Removing and Installing. Refer to → Chapter "Towing Recognition Control Module -J345-, Removing and Installing".

2 - Frame

- For Towing Recognition Control Module -J345-

3 - Information Label

- On the left side of the body at the rear

4 - Power Pivoting Trailer Hitch Button -E474-

- Component Location Overview. Refer to → Electrical Equipment; Rep. Gr.96; Controls; Component Location Overview - Luggage Compartment Controls

5 - Trailer Hitch Bend Angle Sensor -G820-

- Overview. Refer to → Chapter "Overview - Trailer Hitch".

- Removing and Installing. Refer to → Chapter "Trailer Hitch Bend Angle Sensor -G820-, Removing and Installing".

6 - Trailer Socket -U10-

- Overview. Refer to → Chapter "Overview - Trailer Hitch".

- Removing and installing. Refer to → Electrical Equipment General Information; Rep. Gr.96; Trailer Hitch.

7 - Connector

- For Trailer Hitch Bend Angle Sensor -G820-

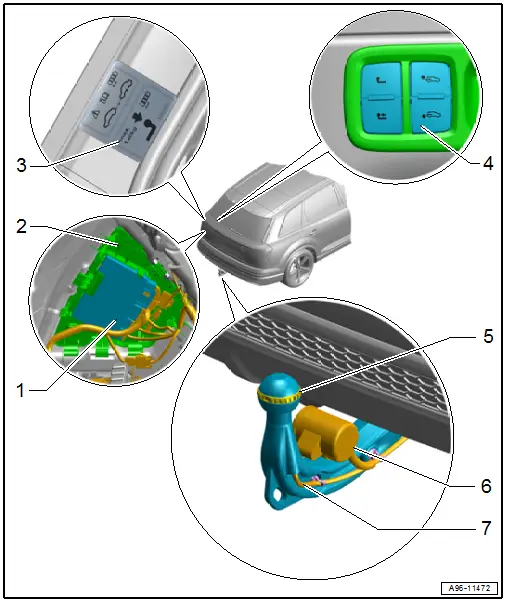

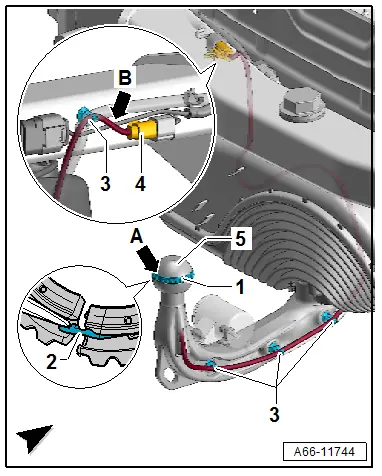

Overview - Trailer Hitch

1 - Trailer Hitch

- Component Location Overview. Refer to → Chapter "Component Location Overview - Trailer Hitch".

- Only removable with the impact member

- Removing and Installing. Refer to → Chapter "Impact Member, Removing and Installing, Vehicles with Trailer Hitch".

2 - Trailer Socket -U10-

- Removing and installing. Refer to → Electrical Equipment General Information; Rep. Gr.96; Trailer Hitch.

3 - Ring on Trailer Hitch Bend Angle Sensor -G820-

- Removing and Installing. Refer to → Chapter "Trailer Hitch Bend Angle Sensor -G820-, Removing and Installing".

4 - Trailer Hitch Bend Angle Sensor -G820-

- Removing and Installing. Refer to → Chapter "Trailer Hitch Bend Angle Sensor -G820-, Removing and Installing".

5 - Towing Recognition Control Module -J345-

- Removing and Installing. Refer to → Chapter "Towing Recognition Control Module -J345-, Removing and Installing".

Trailer Hitch Bend Angle Sensor -G820-, Removing and Installing

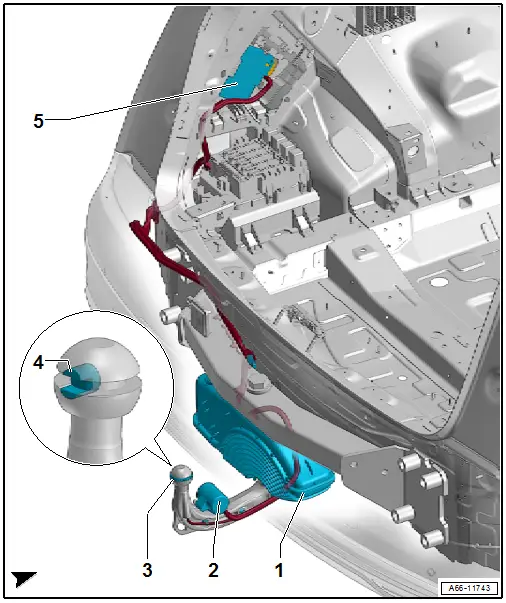

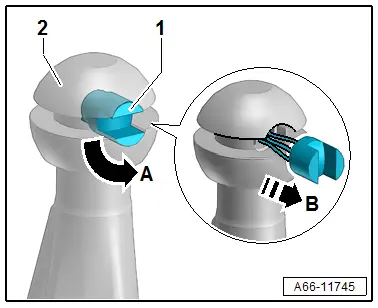

Ring on Trailer Hitch Bend Angle Sensor -G820-, Removing and Installing

Removing

- Push the ring covering -1- at the separating point -arrow A- to the side and release the locking mechanism -2-.

- Open the ring at the separating point -arrow A- and remove it from the ball head -5-.

Installing

Install in reverse order of removal and note the following:

- The smaller ring diameter must face upward.

- The ring locking mechanism must engage audibly.

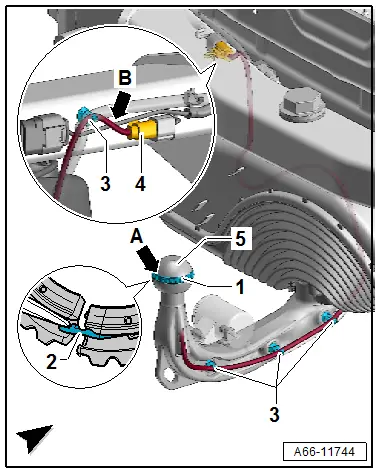

Trailer Hitch Bend Angle Sensor -G820-, Removing and Installing

Removing

- Remove the ring on Trailer Hitch Bend Angle Sensor -G820-.

- Disconnect the cable tie -3- along the connector -4-.

- Disconnect the connector -4- and disconnect the wires near the housing -arrow B-.

- Turn the bend angle sensor -1- 90º -arrow A- and pull it with the wire out of the ball head -2- for the trailer hitch -arrow B-.

Installing

Install in reverse order of removal and note the following:

- The bend angle sensor must rest flush with the ball head.

- Crimp the wires. Refer to → Electrical System General Information; Rep. Gr.97; Wiring Harness and Connectors, Repairing.

Connector Assignment on Connector Housing for Trailer Hitch Bend Angle Sensor -G820-

- Pin 1: red

- Pin 2: black

- Pin 3: yellow

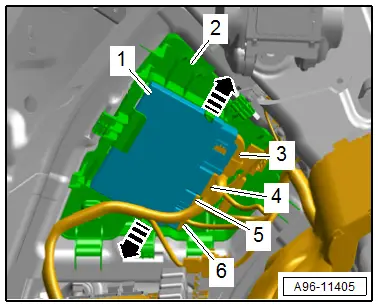

Towing Recognition Control Module -J345-, Removing and Installing

Removing

- Remove the luggage compartment left trim panel. Refer to → Body Interior; Rep. Gr.70; Luggage Compartment Trim Panels; Luggage Compartment Side Trim Panel, Removing and Installing.

- Release the retainers -arrows- and remove the towing recognition control module -1- from the frame -2-.

- Disconnect the connectors -3 through 6-.

Installing

Install in reverse order of removal and note the following:

- If the control module is being replaced, the "Replace control module" function for the respective control module must be selected. Use the → Vehicle diagnostic tester, Diagnose.

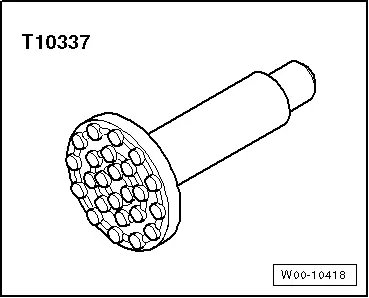

Special Tools

Special tools and workshop equipment required

- Engine/Gearbox Jack - Gearbox Support -T10337-

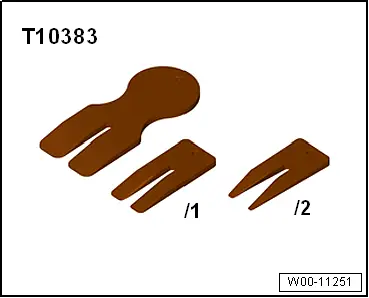

- Wedge Set -T10383-

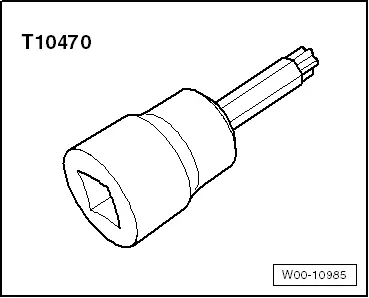

- Socket - Torx T50 -T10470-

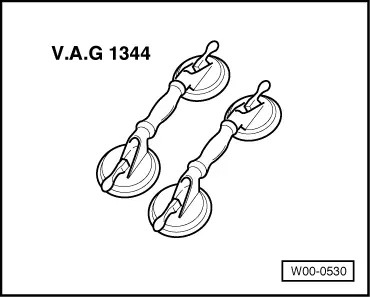

- Double Suction Lifter -VAG1344-

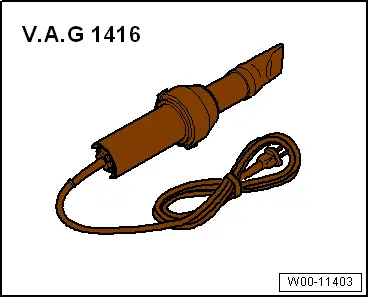

- Wiring Harness Repair Set - Hot Air Blower -VAS1978/14A-

- Container of the Coolant Collection System -VAS5014- or the Shop Crane - Drip Tray -VAS6208-

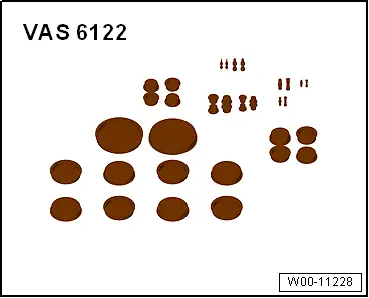

- Engine Bung Set -VAS6122-

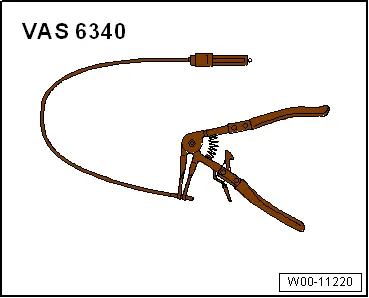

- Hose Clip Pliers -VAS6340-

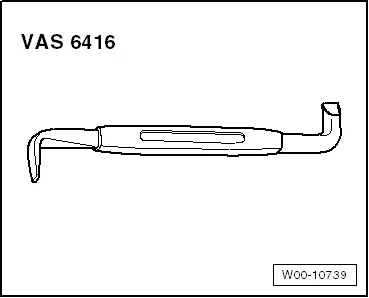

- Angled Screwdriver -VAS6416-

- Engine and Gearbox Jack -VAS6931-

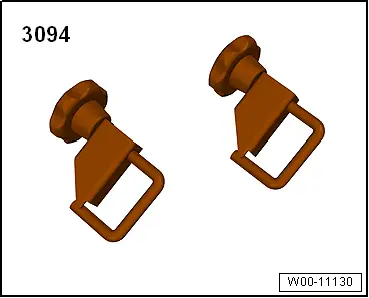

- Hose Clamps - Up To 25 mm -3094-

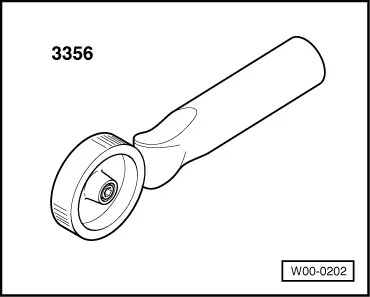

- Roller -3356-

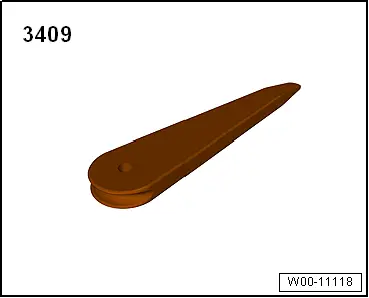

- Trim Removal Wedge -3409-

- Hand drill

- 5 mm drill bit

Revision History

DRUCK NUMBER: A005A011121