Audi Q7: Door, Removing and Installing

Removing

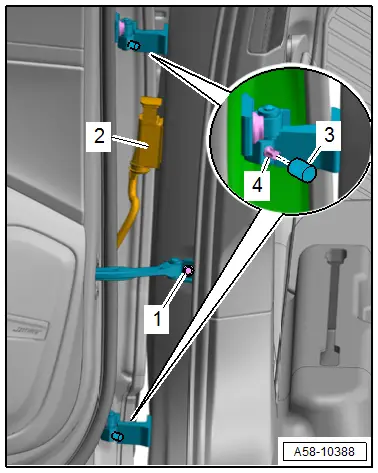

- Disconnect the door connector -2- from the B-pillar. Refer to → Electrical Equipment; Rep. Gr.97; Connectors.

- Tape off the B-pillar in the door arrester area using adhesive tape, so that the paint will not be damaged.

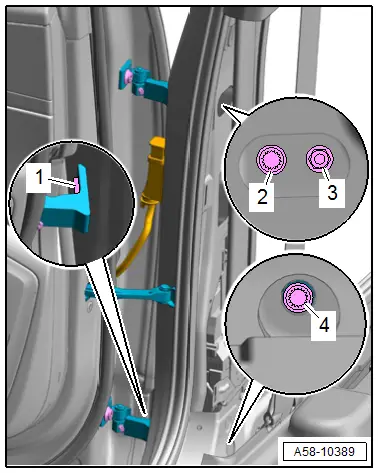

- Remove the bolt -1- for the door arrester.

- Remove the upper and lower cap -3-.

- Remove the set screw -4- from the top and bottom of the door hinge.

- Carefully remove the door upward out of the door hinges.

Installing

Install in reverse order of removal and note the following:

- Do not make any adjustments after installing the door.

Tightening Specifications

- Refer to → Chapter "Overview - Door"

Door, Adjusting

Adjustment Dimensions

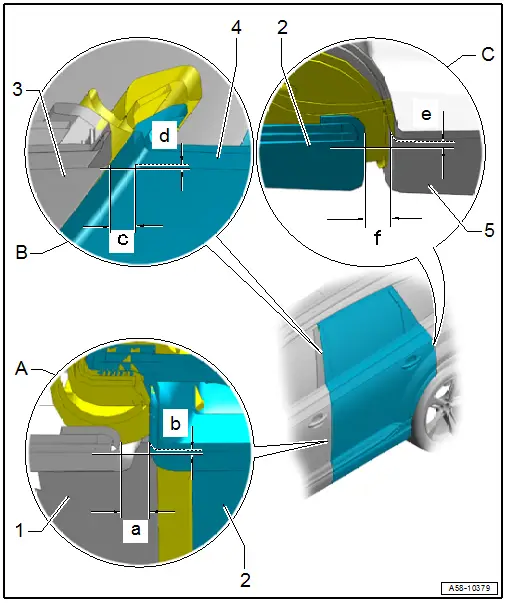

A - Rear Door to Front Door - Bottom

- Gap dimension -a- = 4.0 -0.3/+0.7 mm

- Flush dimension -b- = 0/-1.0 mm

- Parallel alignment = 0.5 mm

-1- Front door

-2- Rear door

B - Rear Door to Front Door - Top

- Gap dimension -c- = 3.8 +- 1.0 mm

- Flush dimension -d- = 0.5/-1.0 mm

- Parallel alignment = 0.5 mm

-3- Front B-pillar trim

-4- Rear B-pillar trim

C - Rear Door to Rear Side Panel

- Gap dimension -f- = 3.2 +- 0.5 mm

- Flush dimension -e- = 0/- 1.0 mm.

- Parallel alignment = 0.5 mm

-2- Rear door

-5- Rear side panel

Door Adjustment, Checking

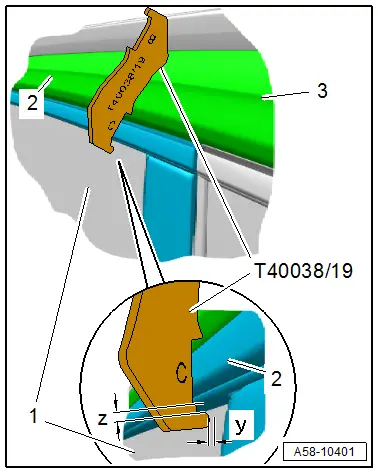

Check points for the door adjustments using the -T40038/19-.

Check height and side adjustment at check point "B" using -T40038/19-.

Check height and side adjustment at check point "C" using -T40038/19-.

- Adjustment dimensions. Refer to → Chapter "Adjustment Dimensions".

Special tools and workshop equipment required

- Gauge - Gap Adjustment -3371-

- Template -T40038/19-

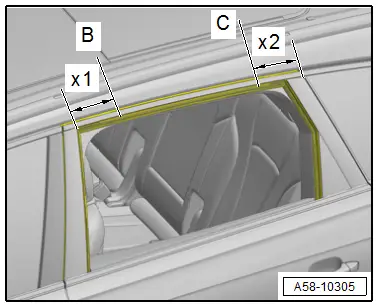

Check Points for Adjusting Door, Using -T40038/19-

- Place the template on the check point:

- Template side "B" on the check point -B- at distance -x1- = 150 mm.

- Template side "C" on the check point -C- at distance -x2- = 150 mm.

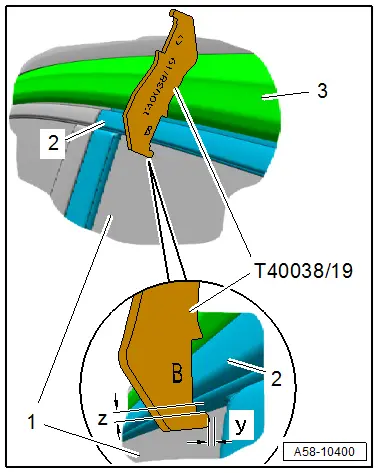

Height and Side Adjustment at Check Point "B", Checking using -T40038/19-

- Place side "B" of the template on the body -3-.

- The contour of the template must completely contact the body.

- At the correct height adjustment the bottom of the trim molding -2- must be within the tolerance -z- of the template contour.

- At the correct side adjustment the dimension -y- must be between the template and the dimension -1- within the tolerance.

- -y- = 0/-1.0 mm.

Height and Side Adjustment at Check Point "C", Checking using -T40038/19-

- Place side "C" of the template on the body -3-.

- The contour of the template must completely contact the body.

- At the correct height adjustment the bottom of the trim molding -2- must be within the tolerance -z- of the template contour.

- At the correct side adjustment the dimension -y- must be between the template and the dimension -1- within the tolerance.

- -y- = 0/-1.0 mm.

Length Adjustment

- Adjustment dimensions. Refer to → Chapter "Adjustment Dimensions".

Procedure

- Remove the B-pillar air duct. Refer to → Body Interior; Rep. Gr.70; Vehicle Interior Trim Panels; B-Pillar Trim, Removing and Installing.

- Loosen the bolts -1, 2 and 4- and nut -3- on the hinge and on the B-pillar.

- Adjust the door lengthwise.

- Tighten the bolts and nuts.

Tightening Specifications

- Refer to → Chapter "Overview - Door"

Side Adjustment

- Adjustment dimensions. Refer to → Chapter "Adjustment Dimensions".

Procedure

- Remove the B-pillar air duct. Refer to → Body Interior; Rep. Gr.70; Vehicle Interior Trim Panels; B-Pillar Trim, Removing and Installing.

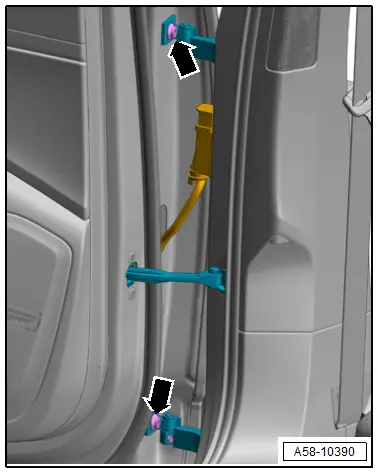

- Loosen the bolts -arrows- on the upper and lower hinge.

- Adjust the door to the center of the vehicle.

- Tighten the bolts.

Tightening Specification

- Refer to → Chapter "Overview - Door Handle and Door Lock"

Striker, Adjusting

- Adjustment dimensions. Refer to → Chapter "Adjustment Dimensions".

Procedure

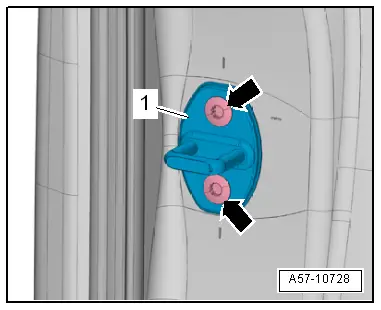

- Loosen the bolts -arrows-.

- Slide the striker -1- until the door is flush with the body contour.

- When adjusting the striker, move it only toward the center of the vehicle.

- Do not adjust the door height using the striker because the door lock will be damaged.

- When adjusted correctly, the striker must engage in the center of the door lock.

- Tighten the bolts.

Tightening Specifications

- Refer to → Chapter "Overview - Door Handle and Door Lock"