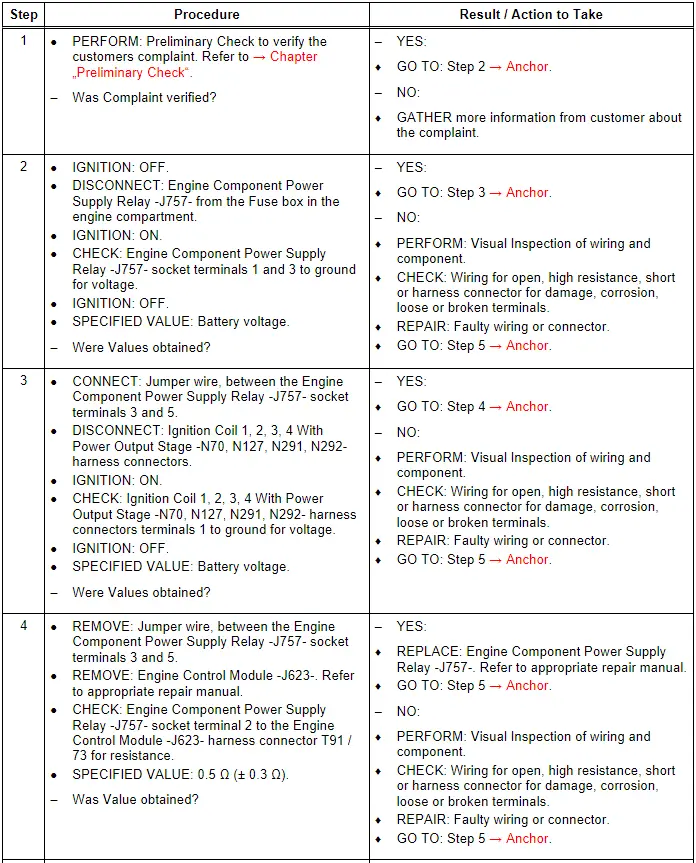

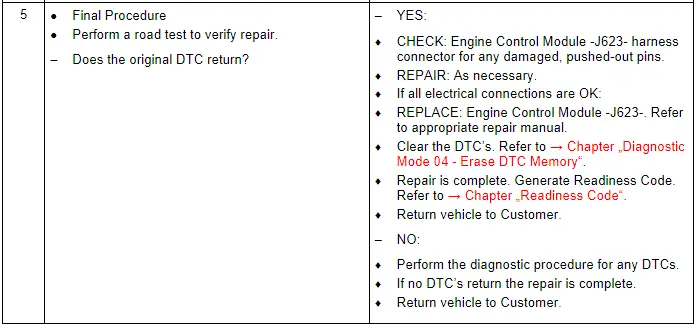

Audi Q7: Engine Component Power Supply Relay - J757-, Checking

General Description

The following procedure is used to diagnose the Engine Component Power Supply Relay -J757- and the power supply voltage that is provided to the engine components.

Special tools and workshop equipment required

- Multimeter.

- Wiring Diagram.

- Scan Tool.

Test requirements

- Fuses OK.

- Battery voltage OK.

- Switch OFF all electrical and electronic accessories.

- Vehicles with automatic transmission, ensure the selector lever position is in "P".

- Vehicles with manual transmission, ensure the shifter lever position is in "N" with the parking brake applied.

- Coolant temperature: ≥ 80º C.

- Observe all safety precautions: → Chapter "Safety Precautions".

- View clean working conditions: → Chapter "Clean Working Conditions".

- For Hybrid vehicles, refer to: → Chapter "High Voltage System General Warnings".

Test Procedure

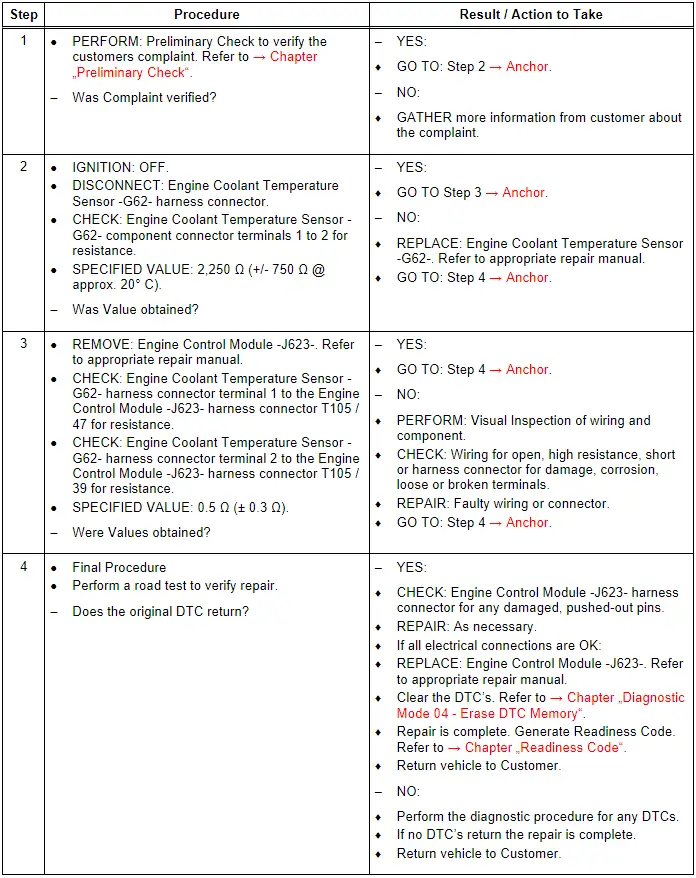

Engine Coolant Temperature Sensor - G62-, Checking

General Description

The Engine Coolant Temperature Sensor -G62- sends information about the current coolant temperature to the Engine Control Module -J623-. It uses the coolant temperature as a correction value for calculating the injection quantity.

Special tools and workshop equipment required

- Multimeter.

- Wiring Diagram.

- Scan Tool.

Test requirements

- Fuses OK.

- Battery voltage OK.

- Switch OFF all electrical and electronic accessories.

- Vehicles with automatic transmission, ensure the selector lever position is in "P".

- Vehicles with manual transmission, ensure the shifter lever position is in "N" with the parking brake applied.

- Coolant temperature: ≥ 80º C.

- Observe all safety precautions: → Chapter "Safety Precautions".

- View clean working conditions: → Chapter "Clean Working Conditions".

- For Hybrid vehicles, refer to: → Chapter "High Voltage System General Warnings".

Test Procedure

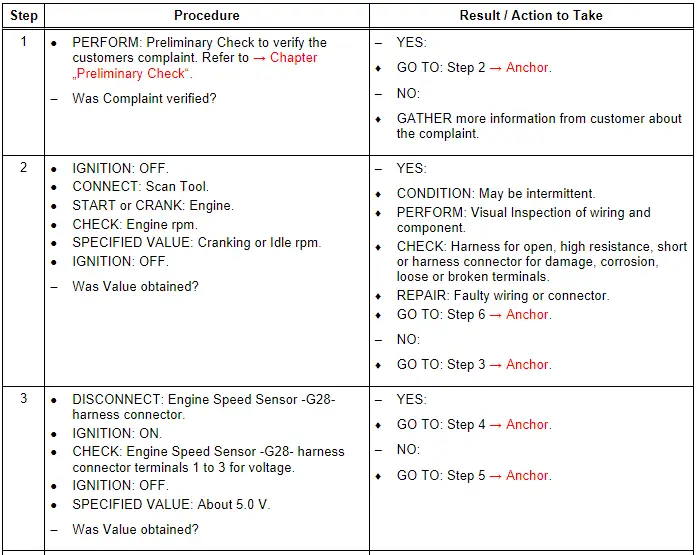

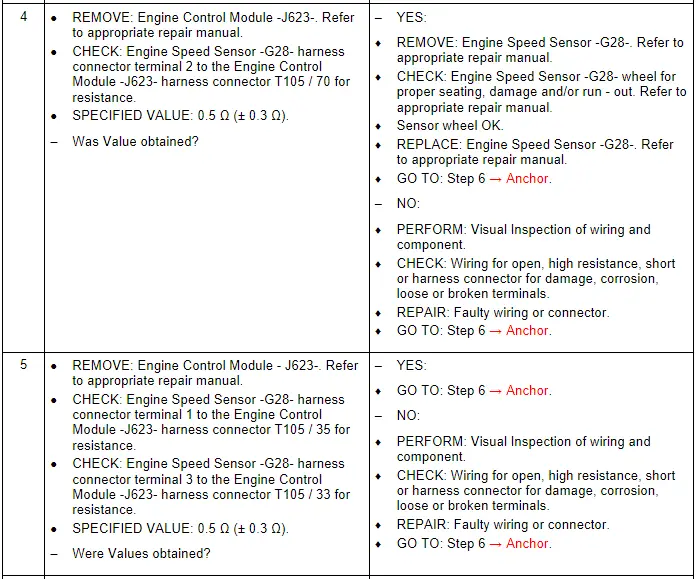

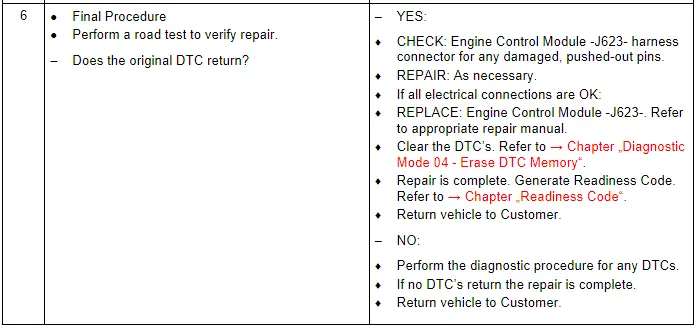

Engine Speed Sensor - G28-, Checking

General Description

The Engine Speed Sensor -G28- detects rpm and reference marks from a toothed wheel on the crankshaft. Without an engine speed signal, the engine will not start. If the engine speed signal fails while the engine is running, the engine will stop immediately.

Special tools and workshop equipment required

- Multimeter.

- Wiring Diagram.

- Scan Tool.

Test requirements

- Fuses OK.

- Battery voltage OK.

- Switch OFF all electrical and electronic accessories.

- Vehicles with automatic transmission, ensure the selector lever position is in "P".

- Vehicles with manual transmission, ensure the shifter lever position is in "N" with the parking brake applied.

- Coolant temperature: ≥ 80º C.

- Observe all safety precautions: → Chapter "Safety Precautions".

- View clean working conditions: → Chapter "Clean Working Conditions".

- For Hybrid vehicles, refer to: → Chapter "High Voltage System General Warnings".

Test Procedure

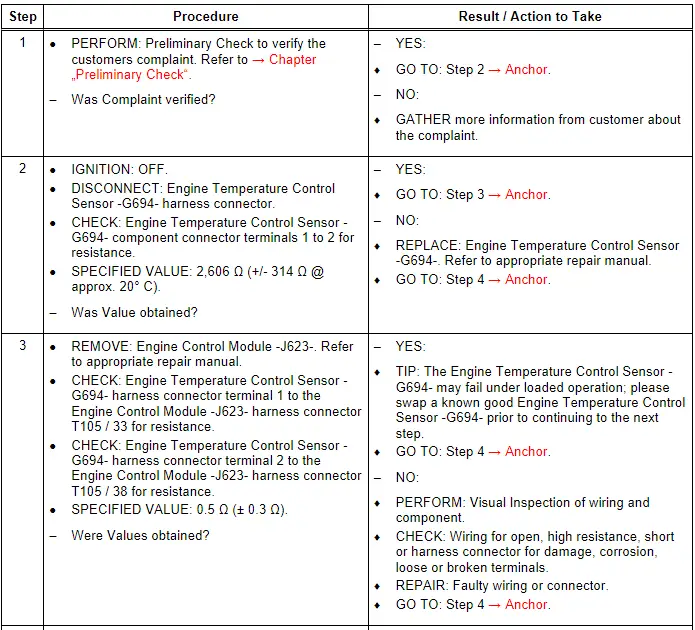

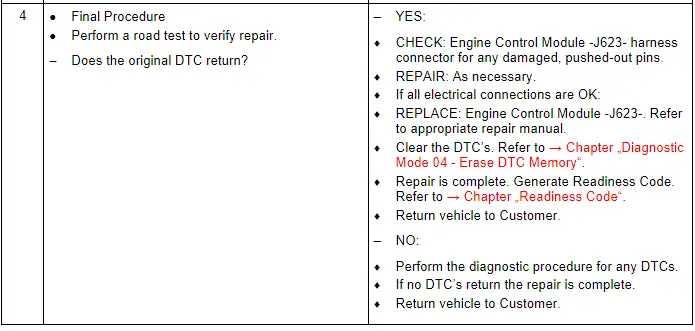

Engine Temperature Control Sensor - G694-, Checking

General Description

The Engine Temperature Control Sensor -G694- sends information about the current coolant temperature to the Engine Control Module -J623-. It uses the coolant temperature as a correction value for calculating the injection quantity.

Special tools and workshop equipment required

- Multimeter.

- Wiring Diagram.

- Scan Tool.

Test requirements

- Fuses OK.

- Battery voltage OK.

- Switch OFF all electrical and electronic accessories.

- Vehicles with automatic transmission, ensure the selector lever position is in "P".

- Vehicles with manual transmission, ensure the shifter lever position is in "N" with the parking brake applied.

- Coolant temperature: ≥ 80º C.

- Observe all safety precautions: → Chapter "Safety Precautions".

- View clean working conditions: → Chapter "Clean Working Conditions".

- For Hybrid vehicles, refer to: → Chapter "High Voltage System General Warnings".

Test Procedure

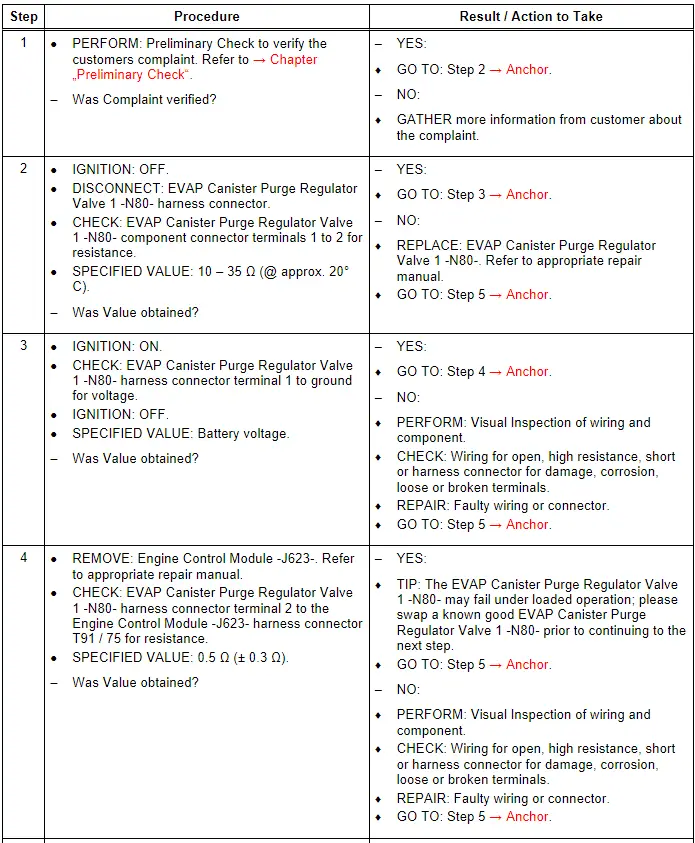

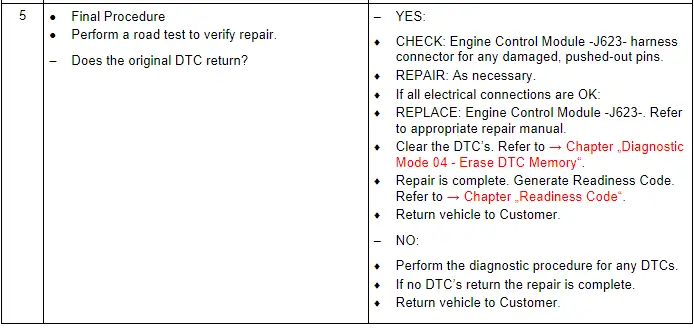

EVAP Canister Purge Regulator Valve 1 - N80-, Checking

General Description

The EVAP system is designed so the admission of fuel vapors takes place only at idle and at light part-throttle. The EVAP Canister Purge Regulator Valve 1 -N80- is map-activated by the Engine Control Module -J623- to accomplish this task.

Special tools and workshop equipment required

- Multimeter.

- Wiring Diagram.

- Scan Tool.

Test requirements

- Fuses OK.

- Battery voltage OK.

- Switch OFF all electrical and electronic accessories.

- Vehicles with automatic transmission, ensure the selector lever position is in "P".

- Vehicles with manual transmission, ensure the shifter lever position is in "N" with the parking brake applied.

- Coolant temperature: ≥ 80º C.

- Observe all safety precautions: → Chapter "Safety Precautions".

- View clean working conditions: → Chapter "Clean Working Conditions".

- For Hybrid vehicles, refer to: → Chapter "High Voltage System General Warnings".

Test Procedure