Audi Q7: Headlamp, Adjusting

- The following test and adjustment description applies to all countries.

- However, national guidelines or regulations of the country must be observed.

HID Headlamp, Adjusting

Special tools and workshop equipment required

- Headlamp Adjusting Unit -VAS5209B-

- Headlamp Adjusting Unit -VAS621001-

- Vehicle Diagnostic Tester

Test and Adjusting Conditions

- Tire pressure is OK.

- The headlamp glass must be clean and dry.

- The headlamp glass must not be damaged.

- Headlamp reflectors and bulbs are OK.

Vehicles with Coil Springs:

- The vehicle must be under load.

Vehicle load on driver seat in otherwise unloaded vehicle (curb weight).

- One person or 75 kg (165.34 lbs).

The curb weight is the weight of the operational vehicle with a completely full fuel tank, including the weight of all equipment carried while in operation.

- Fuel tank: at least 90% full.

- Equipment: for example, spare tire, tools, vehicle jack, fire extinguisher, etc.

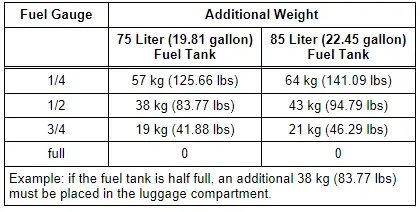

If the fuel tank is not at least 90% full, the load must be created as follows.

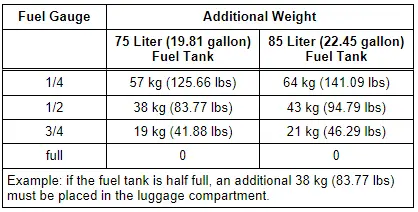

- Check the fuel tank fill level in the instrument cluster fuel gauge and compare it with the following table. Place additional weight in the luggage compartment, if necessary.

Note

Note

Use containers filled with water as additional weight (a five liter container filled with water weighs approximately five kg (11.02 gallons) ).

Vehicles with Air Suspension

- The compressed air reservoir must be filled. Start the engine and let it run in the neutral position for approximately two minutes.

Continuation for All Vehicles

- The electro-mechanical parking brake must not be engaged so that the vehicle is not under stress.

- The vehicle and headlamp adjusting unit must be on a level surface.

- The headlamp adjusting unit must be aligned to the vehicle. Refer to the Headlamp Adjusting Unit Operating Instructions.

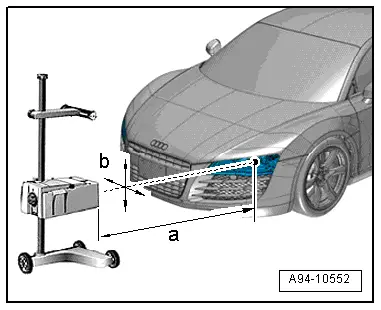

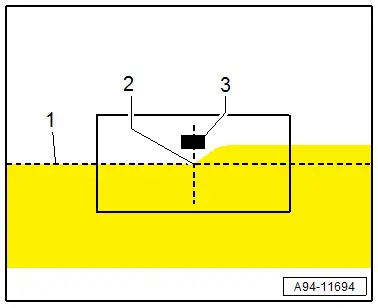

- The headlamp adjusting unit must be distance -a- = 10 to 50 cm in front of the headlamp and should not deviate more than dimension -b- = 3 cm from the center point of the headlamp.

- The angle dimension is set on the headlamp adjusting unit. Refer to the Headlamp Adjusting Unit Operating Instructions.

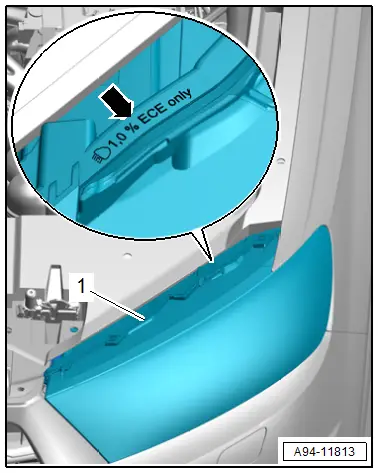

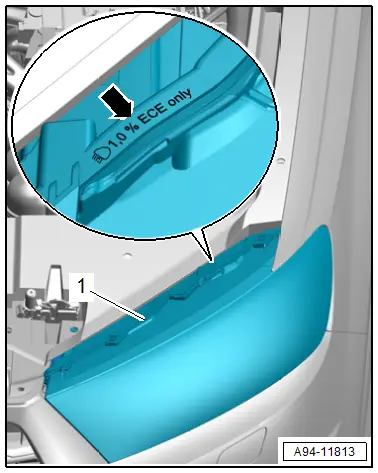

- The angle dimension -arrow- is stamped for ECE countries on the upper edge of the headlamp -1- in "%".

- The standard angle dimension for the USA is 0.7%.

Note

Note

The percentage value is based on a 10 meter projection distance. An angle dimension of 1.0%, for example, converts to 10 cm.

Preliminary Work

- Turn the light switch to "low beam" - not to "Auto".

- Close all the doors and the rear lid and keep them closed for the duration of the testing/adjusting procedure.

Procedure

- Connect the Vehicle Diagnostic Tester.

- Select the Diagnostic mode and start.

- Select the Test plan tab.

- Press the Select individual tests button and select the following one after the other:

- Body

- Electrical Equipment

- 01 - OBD-capable systems

- 09 - Vehicle Electrical System Control Module J519

- 09 - Vehicle Electrical System Control Module functions

- 09 - Adjusting headlamps

Note

Note

- The headlamps move into the basic setting with this program.

- If the vehicle has air suspension, the suspension will move into the air suspension normal level at the same time.

- Start the selected program and follow the instructions in the Vehicle Diagnostic Tester display.

- During the program, it will be asked to perform a headlamp adjustment.

Headlamp Adjustment

Note

Note

The image and the following description apply to the headlamp adjusting unit. Pay attention to the Owner's Manual for the digital headlamp adjusting units for example -VAS5209B- or -VAS621001-. Refer to the Headlamp Adjusting Unit Owner's Manual.

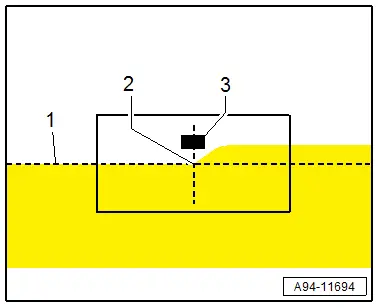

- The horizontal cut-off line must touch the cut-off line -1- on the adjusting unit test surface.

- The bend point -2- between the left horizontal part and the right rising part of the cut-off line must run vertically through the central mark -3-. The bright core of the light beam must be to the right of the vertical.

Note

Note

- To determine the bend point -2- more easily, cover and uncover the left half of the headlamp (seen in direction of travel) several times. Then check the low beam again.

- After adjusting the low beam according to the instructions, the center of the high beam light beam must be on the central marking -3-.

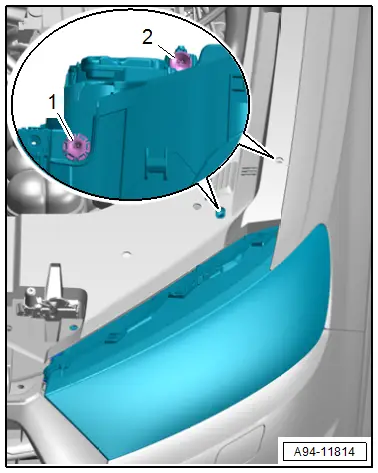

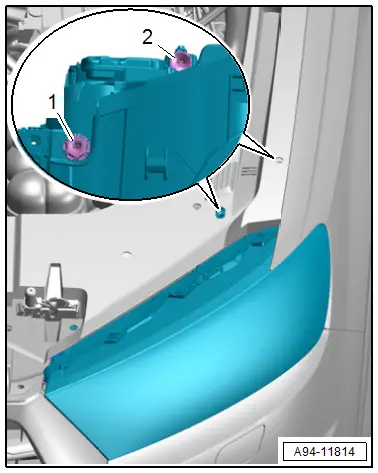

- To adjust the height of the headlamp, set the cut-off line just above the dividing line with the adjustment screw -1-.

- Then adjust the cut-off line, starting from the top, on the dividing line.

- For side adjustment, turn the adjusting screw -2-.

Note

Note

The right headlamp layout is a mirror image.

- Vehicles with air suspension: after successful headlamp adjustment, follow the instructions on the Vehicle Diagnostic Tester display in order to leave the air suspension normal level.

- Disconnect the diagnostic connector.

LED Headlamp, Adjusting

Special tools and workshop equipment required

- Headlight Adjusting Unit -VAS5209B-

- Headlight Adjusting Unit -VAS621001-

Test and Adjusting Conditions

- Tire pressure is OK.

- The headlamp glass must be clean and dry.

- The headlamp glass must not be damaged.

- Headlamp reflectors and bulbs are OK.

- Vehicles with Matrix LED headlamps: Only use the -VAS5209B- or -VAS621001- for the headlamp adjustment, because after the headlamp adjustment the Matrix LED headlamps must be calibrated. Refer to → Chapter "Headlamps, Calibrating".

Vehicles with Coil Springs

- The vehicle must be under load.

Vehicle load on driver seat in otherwise unloaded vehicle (curb weight).

- One person or 75 kg (165.34 lbs)

The curb weight is the weight of the operational vehicle with a completely full fuel tank, including the weight of all equipment carried while in operation.

- Fuel tank: at least 90% full.

- Equipment: for example, spare tire, tools, vehicle jack, fire extinguisher, etc.

If the fuel tank is not at least 90% full, the load must be created as follows.

- Check the fuel tank fill level in the instrument cluster fuel gauge and compare it with the following table. Place additional weight in the luggage compartment, if necessary.

Note

Note

Use containers filled with water as additional weight (a five liter container filled with water weighs approximately five kg (11.02 lbs) ).

Vehicles with Air Suspension

- The compressed air reservoir must be filled. Start the engine and let it run in the neutral position for approximately two minutes.

Continuation for All Vehicles

- The electro-mechanical parking brake must not be engaged so that the vehicle is not under stress.

- The vehicle and headlamp adjusting unit must be on a level surface.

- The headlamp adjusting unit must be aligned to the vehicle. To do this, slide the headlamp adjusting unit a distance of 00 mm (3.93 in.) centered in front of the vehicle and aligned to the vehicle front. Refer to Headlamp Adjusting Owner's Manual.

- Slide the headlamp adjusting unit in front of the corresponding headlamp and check the alignment again.

- The headlamp adjusting unit must be aligned at the center of the marked reflector segment -arrow-.

- The angle dimension is set on the headlamp adjusting unit. Refer to the Headlamp Adjusting Unit Operating Instructions.

- The angle dimension -arrow- is stamped for ECE countries on the upper edge of the headlamp -1- in "%".

- The standard angle dimension for the USA is 0.7%.

Note

Note

The percentage value is based on a 10 meter projection distance. An angle dimension of 1.0%, for example, converts to 10 cm.

Preliminary Work

- Turn the light switch to "low beam" - not to "Auto".

- Close all the doors and the rear lid and keep them closed for the duration of the testing/adjusting procedure.

Procedure

- Connect the Vehicle Diagnostic Tester.

- Select the Diagnostic mode and start.

- Select the Test plan tab.

- Press the Select individual tests button and select the following one after the other:

- Body

- Electrical Equipment

- 01 - OBD-capable systems

- 09 - Vehicle Electrical System Control Module J519

- 09 - Vehicle Electrical System Control Module functions

- 09 - Adjusting headlamps

Note

Note

- The headlamps move into the basic setting with this program.

- If the vehicle has air suspension, the suspension will move into the air suspension normal level at the same time.

- Start the selected program and follow the instructions in the Vehicle Diagnostic Tester display.

- During the program, it will be asked to perform a headlamp adjustment.

Headlamp Adjustment

Note

Note

The image and the following description apply to the headlamp adjusting unit. Pay attention to the Owner's Manual for the digital headlamp adjusting units for example -VAS5209B- or -VAS621001-. Refer to the Headlamp Adjusting Unit Owner's Manual.

- The horizontal cut-off line must touch the cut-off line -1- on the adjusting unit test surface.

- The bend point -2- between the left horizontal part and the right rising part of the cut-off line must run vertically through the central mark -3-. The bright core of the light beam must be to the right of the vertical.

Note

Note

- To determine the bend point -2- more easily, cover and uncover the left half of the headlamp (seen in direction of travel) several times. Then check the low beam again.

- After adjusting the low beam according to the instructions, the center of the high beam light beam must be on the central marking -3-.

- To adjust the height of the headlamp, set the cut-off line just above the dividing line with the adjustment screw -1-.

- Then adjust the cut-off line, starting from the top, on the dividing line.

- For side adjustment, turn the adjusting screw -2-.

Note

Note

The right headlamp layout is a mirror image.

- Vehicles with air suspension: after the headlamp adjustment has been successful, follow the instructions on the Vehicle Diagnostic Tester display in order to leave the air suspension normal level.

- Disconnect the data link connector.