Audi Q7: High Pressure Pump

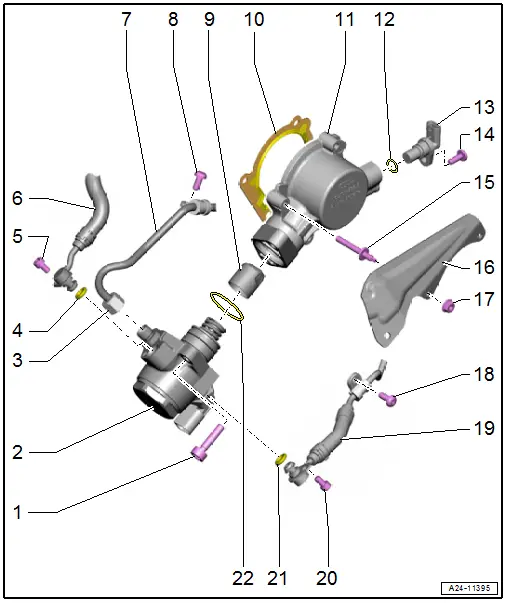

Overview - High Pressure Pump

1 - Bolt

- Tightening specification and sequence. Refer to → Fig. "High Pressure Pump - Tightening Specification and Sequence".

2 - High Pressure Pump

- With Fuel Metering Valve -N290-

- Do not disassemble

- Removing and installing. Refer to → Chapter "High Pressure Pump, Removing and Installing".

3 - Union Nut

- 27 Nm

- Coat the threads on the union nut with fuel.

4 - O-Ring

- Replace after removing

5 - Bolt

- 9 Nm

6 - Fuel Supply Hose with Connection

- Low pressure side from the fuel tank

7 - High Pressure Line

- Removing and installing. Refer to → Chapter "High Pressure Pipe, Removing and Installing".

- Do not change the bending shape.

- Check for damage before reinstalling

8 - Bolt

- 9 Nm

9 - Roller Tappet

- Can only be installed in one position

- Coat with clean engine oil before installing

10 - Seal

- Replace after removing

11 - Housing

12 - O-Ring

- Replace after removing

13 - Camshaft Position Sensor -G40-

- Removing and installing. Refer to → Chapter "Camshaft Position Sensor, Removing and Installing".

14 - Bolt

- Tightening specification. Refer to -item 14-

15 - Threaded Pin

- 9 Nm

16 - Protective Plate

- For the high pressure line

17 - Nut

- 9 Nm

18 - Bolt

- 9 Nm

19 - Fuel Supply Hose with Connection

- Low pressure side to the MPI fuel injector

20 - Bolt

- 9 Nm

21 - O-Ring

- Replace after removing

22 - O-Ring

- Replace after removing

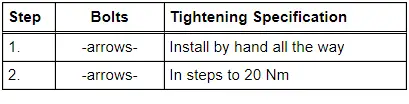

High Pressure Pump - Tightening Specification and Sequence

- Tighten the bolts in stages as follows:

High Pressure Pump, Removing and Installing

Special tools and workshop equipment required

- Torque Wrench 1331 Insert - Reversible Ratchet -VAG1331/1-

- Torque Wrench 1331 Insert - Open Ring Wrench - 14mm -VAG1331/8-

- Engine Bung Set -VAS6122-

- Elbow Assembly Tool -T10118-

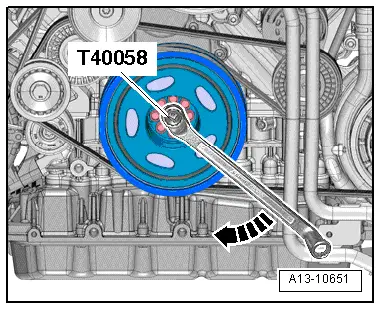

- Crankshaft Socket -T40058-

- Feeler Gauge

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- O-ring - High pressure pump

- O-ring - Fuel supply hose with connection

Removing

Note

Note

- The high pressure pump can only be removed and installed when the engine is cold.

- When installing the high pressure pump, make sure that no dirt enters the fuel system.

- Catch escaping fuel with a cleaning cloth.

- Remove the engine cover. Refer to → Chapter "Engine Cover, Removing and Installing".

- Remove the lock carrier cover. Refer to → Body Exterior; Rep. Gr.63; Front Bumper; Attachments, Removing and Installing.

- Remove the Secondary Air Injection Pump Motor -V101-. Refer to → Chapter "Secondary Air Injection Pump Motor -V101-, Removing and Installing".

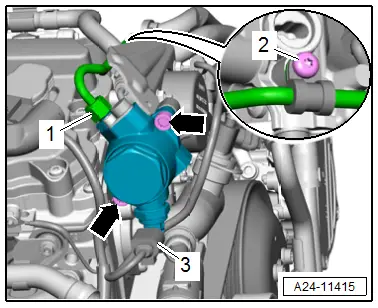

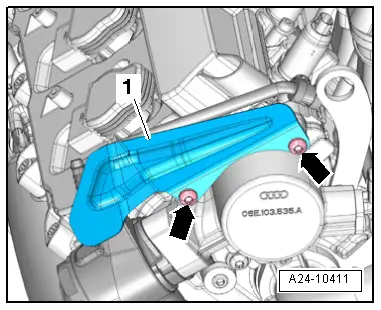

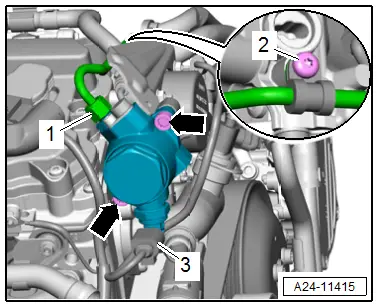

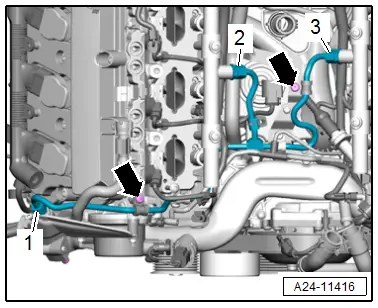

- Remove the nuts -arrows- and the protective plate -1-.

WARNING

WARNING

The fuel system is under pressure.

Risk of injury from fuel spraying out.

- Wear protective eyewear.

- Wear safety gloves.

- Reduce the pressure: place clean cloths around the connection point and carefully open the connection point.

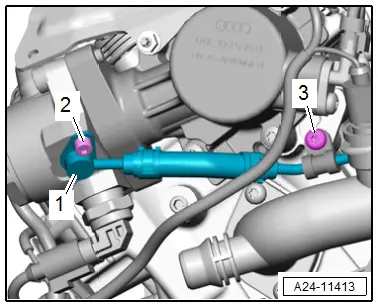

- Disconnect the fuel hose -2-. Refer to → Fuel Supply - Gasoline Engines; Rep. Gr.20; Connector Couplings; Connector Couplings, Disconnecting.

- Always seal the open lines and connections with clean plugs from the Engine Bung Set -VAS6122-.

- Free up the fuel hose from the clips -3-.

Note

Note

Ignore -1-.

- Remove the bolt -2- and the connection -1-.

Note

Note

Ignore -3-.

- Disconnect the connector -3-.

- Remove the bolt -2- on the retaining clamp.

WARNING

WARNING

The fuel system is under pressure.

Risk of injury from fuel spraying out.

- Wear protective eyewear.

- Wear safety gloves.

- Reduce the pressure: place clean cloths around the connection point and carefully open the connection point.

- Remove the union nut -1-.

- Remove the bolts -arrows-.

- Carefully remove the high pressure pump. The roller tappet can remain installed.

Note

Note

Do not bend the high pressure line to a different angle.

Installing

Install in reverse order of removal and note the following:

Note

Note

- Replace the O-rings after removing.

- The high pressure line connections must not show any signs of damage.

- Do not bend the high pressure line to a different angle.

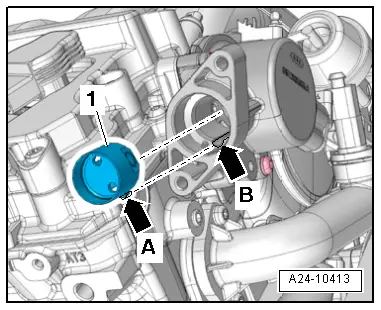

- Check the roller tappet -1- for damage and replace it if necessary.

- Coat the roller tappet with oil and insert it with the tab -arrow A- into the guide -arrow B-.

- Remove the front noise insulation. Refer to → Body Exterior; Rep. Gr.66; Noise Insulation; Noise Insulation, Removing and Installing.

- Turn the crankshaft in the direction of engine rotation in direction of -arrow- using the Crankshaft Socket -T40058- and the offset open-end wrench. While doing so, push the roller tappet into the housing, until it has reached the lowest point.

- Only lift the high pressure line slightly to insert the high pressure pump.

- Push the high pressure pump downward by hand as far as possible until stop.

- While doing so tighten the bolts by hand.

- Tighten the bolts, procedure. Refer to → Fig. "High Pressure Pump - Tightening Specification and Sequence".

- Install the high pressure pipe. Refer to → Chapter "High Pressure Pipe, Removing and Installing".

- Install the engine cover. Refer to → Chapter "Engine Cover, Removing and Installing".

- Install the lock carrier cover. Refer to → Body Exterior; Rep. Gr.63; Front Bumper; Attachments, Removing and Installing.

- Check the fuel system for leaks. Refer to → Chapter "Fuel System Leak Test".

Tightening Specifications

- Refer to → Fig. "High Pressure Pump - Tightening Specification and Sequence"

- Refer to → Chapter "Overview - High Pressure Pump"

- Refer to → Chapter "Overview - Secondary Air Injection System"

- Refer to → Body Exterior; Rep. Gr.66; Noise Insulation; Overview - Noise Insulation.

High Pressure Pipe, Removing and Installing

Special tools and workshop equipment required

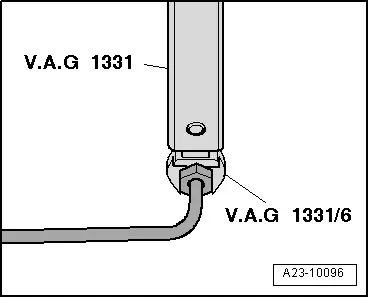

- Torque Wrench 1331 Insert - Open Jaw - 17mm -VAG1331/6-

Removing

- Remove the MPI injection fuel line. Refer to → Chapter "Fuel Line, Removing and Installing".

WARNING

WARNING

The fuel system is under pressure.

Risk of injury from fuel spraying out.

- Wear protective eyewear.

- Wear safety gloves.

- Reduce the pressure: place clean cloths around the connection point and carefully open the connection point.

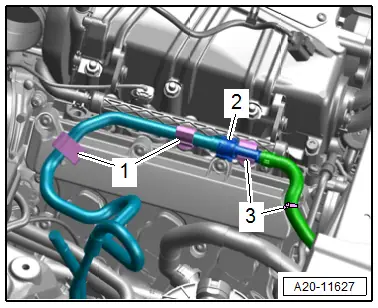

- Remove the union nuts -1, 2 and 3-. If required counterhold on the threaded connection.

- Remove the bolts -arrows-.

Note

Note

- Do not bend the high pressure line to a different angle.

- If the connection -item 3- was loosened or removed, it must be replaced.

Installing

Note

Note

- The high pressure line connections must not show any signs of damage.

- Do not bend the high pressure line to a different angle.

- Then tighten the union nut all the way by hand. While doing so, make sure the high pressure line is resting without tension.

- Counterhold using an open end wrench at the threaded connection hex fitting on the fuel rail and tighten the union nut using a Torque Wrench 1331 5-50Nm -VAG1331- and a Torque Wrench 1331 Insert - Open Jaw - 17mm -VAG1331/6-.

- Only tighten the retaining strap bolt after the high pressure line has been tightened.

- Install the MPI injection fuel line. Refer to → Chapter "Fuel Line, Removing and Installing".

Tightening Specifications

- Refer to → Chapter "Overview - Intake Manifold Lower Section with Fuel Rail"

- Refer to → Chapter "Overview - High Pressure Pump"