Audi Q7: Ignition/Glow Plug System

Ignition System

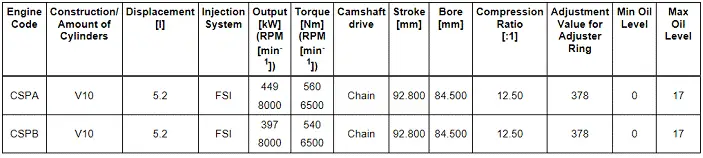

Overview - Ignition System

1 - Bolt

- 9 Nm

2 - Camshaft Position Sensor

- Cylinder Bank 1 (Right)

- Intake side: Camshaft Position Sensor -G40-

- Exhaust side Camshaft Position Sensor 3 -G300-

- Removing and installing. Refer to → Chapter "Camshaft Position Sensor, Removing and Installing".

3 - O-Ring

- Replace after removing

4 - Knock Sensor

- Cylinder bank 1 (right) Knock Sensor 1 -G61-

- Cylinder bank 2 (left) Knock Sensor 2 -G66-

- The contact surfaces between the knock sensor and cylinder block must be free of corrosion, dirt and grease.

- Removing and installing. Refer to → Chapter "Knock Sensor, Removing and Installing".

5 - Bolt

- 25 Nm

6 - Spark Plug

- Remove and install with the Spark Plug Removal Tool -3122B-.

- Tightening specification.

- Replacement interval. Refer to Maintenance Tables.

7 - Ignition Coil with Power Output Stage

- Ignition Coil 1 with Power Output Stage -N70-

- Ignition Coil 2 with Power Output Stage -N127-

- Ignition Coil 3 with Power Output Stage -N291-

- Ignition Coil 4 with Power Output Stage -N292-

- Ignition Coil 5 with Power Output Stage -N323-

- Ignition Coil 6 with Power Output Stage -N324-

- Removing and installing. Refer to → Chapter "Ignition Coils with Power Output Stages, Removing and Installing".

8 - Bolt

- 5 Nm

9 - Wiring Harness

10 - Engine Speed Sensor -G28-

- Removing and installing. Refer to → Chapter "Engine Speed Sensor -G28-, Removing and Installing".

11 - Bolt

- 9 Nm

12 - O-Ring

- Replace after removing

13 - Camshaft Position Sensor

- Cylinder Bank 2 (Left)

- Intake side Camshaft Position Sensor 2 -G163-

- Exhaust side: Camshaft Position Sensor 4 -G301-

- Removing and installing. Refer to → Chapter "Camshaft Position Sensor, Removing and Installing".

14 - Bolt

- 9 Nm

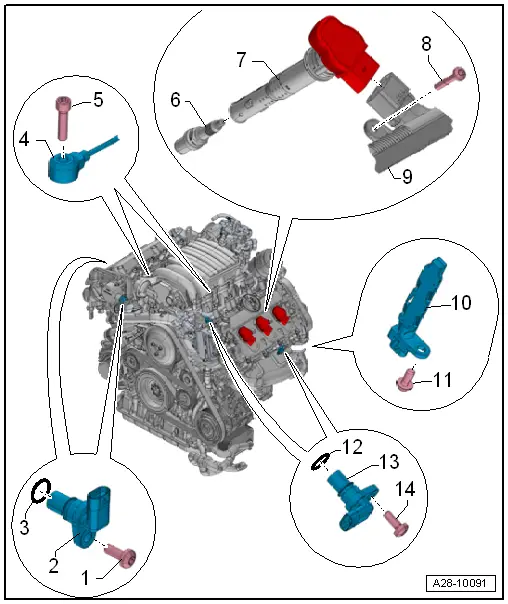

Test Data and Spark Plugs

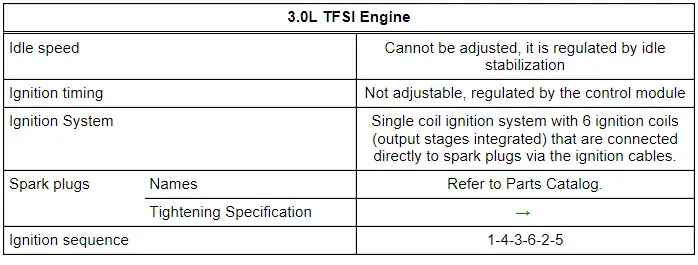

Ignition Coils with Power Output Stages, Removing and Installing

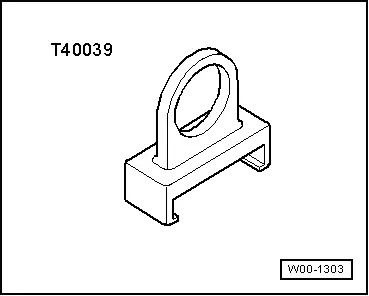

Special tools and workshop equipment required

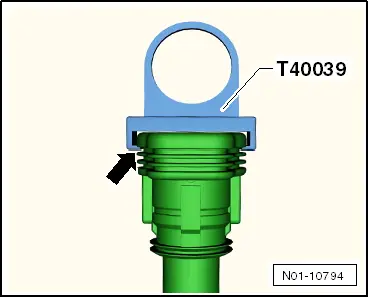

- Puller - Ignition Coil -T40039-

Removing

- Remove the air filter upper section. Refer to → Chapter "Air Filter Housing, Removing and Installing".

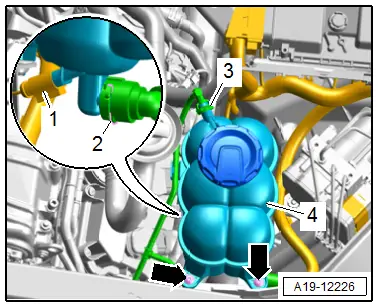

Cylinder Bank 2 (Left):

- Remove the bolts -arrows- and remove the coolant expansion tank -4- upward from the bracket.

- Disconnect the connector -1-.

- Move the coolant reservoir to the side with the hoses -2 and 3- still attached.

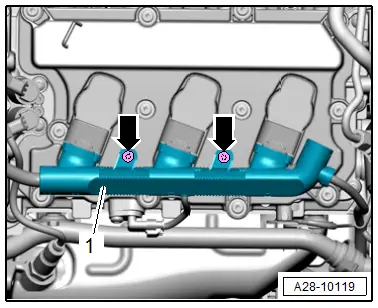

Continuation for Both Sides:

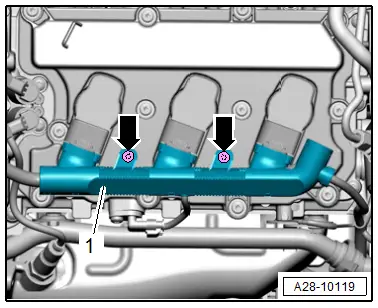

- Remove the bolts -arrows- and disconnect the connectors on the ignition coils.

- Lay the wiring harness -1- slightly underneath.

Note

Note

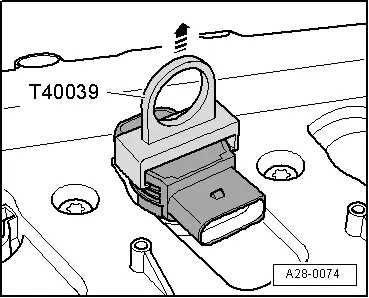

The installation position for cylinder bank 2 (left) is shown in the illustration.

Note

Note

- To remove the ignition coils, place the Puller - Ignition Coil -T40039- on topmost thick rib -arrow- of ignition coil with power output stage.

- The lower ribs may be damaged if they are used.

- Remove the ignition coil in direction of -arrow-.

Installing

Install in reverse order of removal and note the following:

- Install the air filter upper section. Refer to → Chapter "Air Filter Housing, Removing and Installing".

Tightening Specifications

- Refer to → Chapter "Overview - Ignition System"

Knock Sensor, Removing and Installing

Removing

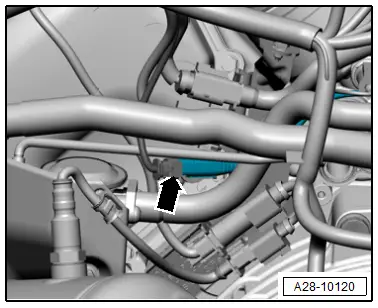

Cylinder Bank 1 (Right):

- Remove the cylinder "2" FSI fuel injector. Refer to → Chapter "Fuel Injectors, Removing and Installing, FSI Fuel Injection".

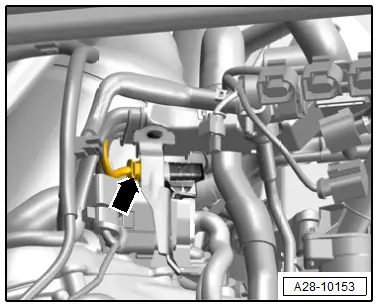

- Remove the connector -arrow- from the bracket, disconnect it, and free up the wire.

Cylinder Bank 2 (Left):

- Remove the cylinder "5" FSI fuel injector. Refer to → Chapter "Fuel Injectors, Removing and Installing, FSI Fuel Injection".

- Remove the connector -arrow- from the bracket, disconnect it, and free up the wire.

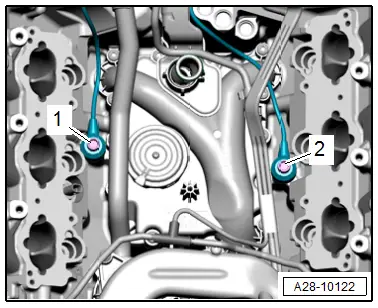

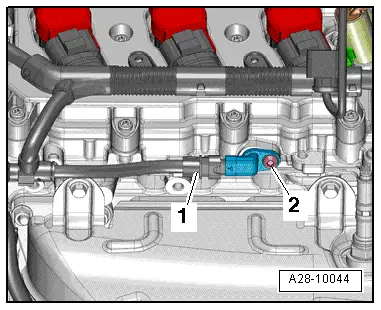

Continuation for Both Sides:

- Remove the bolt -1- for Knock Sensor 1 -G61- or the bolt -2- for the Knock Sensor 2 -G66- and then remove the knock sensor.

Installing

Install in reverse order of removal and note the following:

- Install the FSI fuel injector. Refer to → Chapter "Fuel Injectors, Removing and Installing, FSI Fuel Injection".

Tightening Specifications

- Refer to → Chapter "Overview - Ignition System"

Camshaft Position Sensor, Removing and Installing

Camshaft Position Sensor -G40-, Removing and Installing

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- O-ring - Camshaft position sensor

Removing

- Remove the engine cover. Refer to → Chapter "Engine Cover, Removing and Installing".

- Disconnect the connector -1- on cylinder bank 1.

- Remove the bolt -arrow- and the Camshaft Position Sensor -G40-.

Installing

Install in reverse order of removal and note the following:

Note

Note

Replace the O-ring after removing.

- Install the engine cover. Refer to → Chapter "Engine Cover, Removing and Installing".

Tightening Specifications

- Refer to → Chapter "Overview - Ignition System"

Camshaft Position Sensor 2 -G163-, Removing and Installing

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- O-ring - Camshaft position sensor

Removing

- Remove the engine cover. Refer to → Chapter "Engine Cover, Removing and Installing".

- Disconnect the connector -1- on cylinder bank 2.

- Remove the bolt -arrow- and the Camshaft Position Sensor 2 -G163-.

Installing

Install in reverse order of removal and note the following:

Note

Note

Replace the O-ring after removing.

- Install the engine cover. Refer to → Chapter "Engine Cover, Removing and Installing".

Tightening Specifications

- Refer to → Chapter "Overview - Ignition System"

Camshaft Position Sensor 3 -G300-, Removing and Installing

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- O-ring - Camshaft position sensor

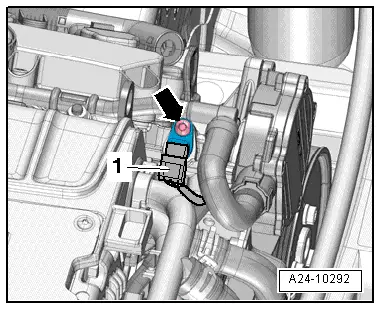

Removing

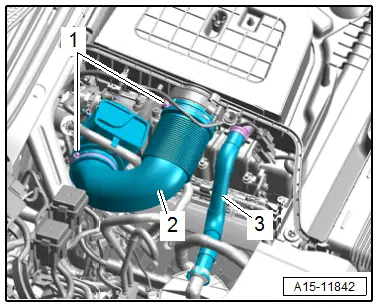

- Loosen the hose clamps -1- and remove the air duct pipe -2-.

Note

Note

Ignore -3-.

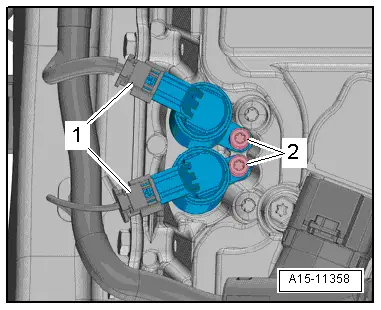

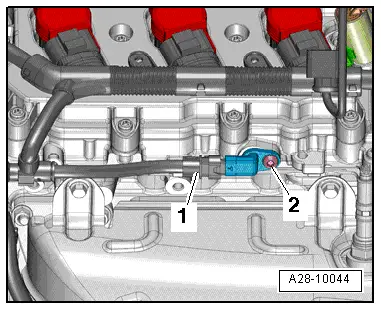

- Disconnect the connectors -1- on the camshaft adjustment valves.

Note

Note

Ignore -2-.

- Remove the bolts -arrows- and disconnect the connectors on the ignition coils.

- Press the wiring harness upward slightly.

- Disconnect the connector -1-.

- Remove the bolt -2- and remove the camshaft position sensor.

Note

Note

The installation position for the Camshaft Position Sensor 4 -G301- on cylinder bank 2 (left) is shown.

Installing

Install in reverse order of removal and note the following:

Note

Note

- Replace the O-ring after removing.

- Secure all hose connections with hose clamps that match the ones used in series production. Refer to the Parts Catalog.

Tightening Specifications

- Refer to → Chapter "Overview - Ignition System"

- Refer to → Chapter "Overview - Charge Air Hose Connections"

Camshaft Position Sensor 4 -G301-, Removing and Installing

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- O-ring - Camshaft position sensor

Removing

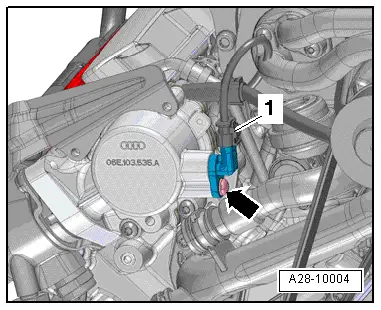

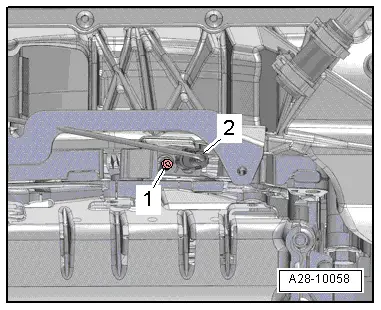

- Remove the air filter upper section. Refer to → Chapter "Air Filter Housing, Removing and Installing".

- Disconnect the connector -1-.

- Remove the bolt -2- and remove the camshaft position sensor.

Installing

Install in reverse order of removal and note the following:

Note

Note

Replace the O-ring after removing.

- Install the air filter upper section. Refer to → Chapter "Air Filter Housing, Removing and Installing".

Tightening Specifications

- Refer to → Chapter "Overview - Ignition System"

Engine Speed Sensor -G28-, Removing and Installing

Removing

- Remove the rear noise insulation. Refer to → Body Exterior; Rep. Gr.66; Noise Insulation; Noise Insulation, Removing and Installing.

- Disconnect the connector -2-.

- Remove the bolt -1- and the Engine Speed Sensor -G28-.

Installing

Install in reverse order of removal.

Tightening Specifications

- Refer to → Chapter "Overview - Ignition System"

- Refer to → Body Exterior; Rep. Gr.66; Noise Insulation; Overview - Noise Insulation.

Special Tools

Special tools and workshop equipment required

- Puller - Ignition Coil -T40039-

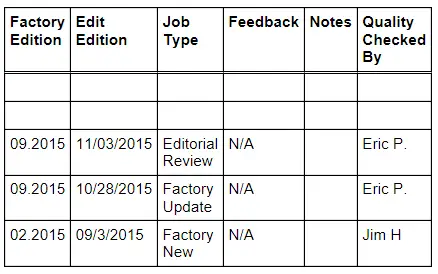

Revision History

DRUCK NUMBER: A0Q5A020921

Oil Gauge Tester T40178 Service Values

Engine Overview with Adjustment Values, Gauge - Oil Gauge Tester (T40178)

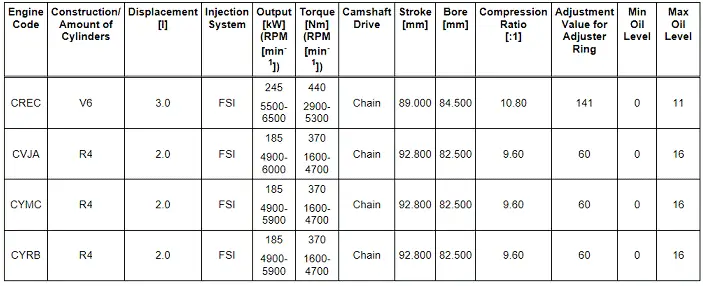

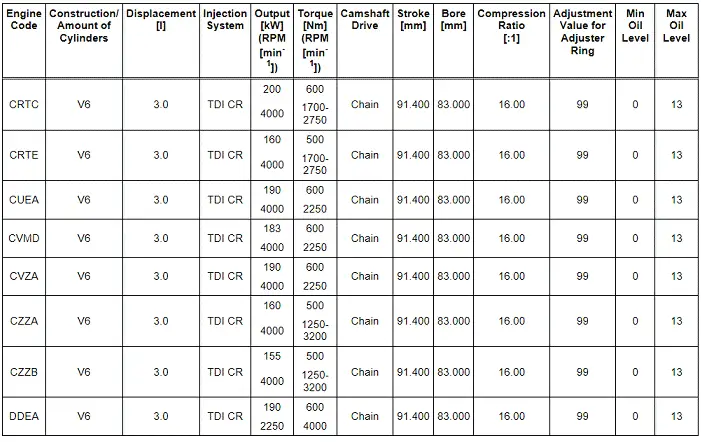

Audi Q7 - Model Code 4M

Gasoline Engines

Diesel Engines

Audi R8 - Model Code 4S

Gasoline Engines