Audi Q7: Left Center Vent Motor -V110-, Removing and Installing

Note

Note

- Depending on vehicle equipment, there are different versions of the A/C system for the Audi Q7. Make sure to use the correct version and pay attention to the allocation of different components. Refer to → Chapter "A/C System Versions" and Parts Catalog.

- The Left Center Vent Motor -V110- is only installed on vehicles with a "Mix" or "High" A/C system. On vehicles with a "Low" or "Mid" A/C system, the left door is actuated using the lever and a curved washer from the Left Side Vent Motor -V299-.

- Currently in this vehicle, all actuators are identical in construction. During the basic setting, the actuators are assigned and adapted corresponding to the switching sequence of the wiring. If this sequence does not conform with the specification, the actuators will adapt incorrectly and the door control will be wrong. Refer to → Chapter "Main Wiring Diagram for A/C System Actuators".

- Therefore, perform the basic setting for the A/C system after installation of the adjustment motor. Refer to Vehicle Diagnostic Tester in the "Guided Fault Finding" function.

- Using the "output diagnostic test mode" and "basic setting" functions, the activation of A/C system electrical components can be tested if necessary (for example, allocation test). Refer to Vehicle Diagnostic Tester in the "Guided Fault Finding" function.

- After installing a new actuator, check the activation via the Front A/C Display Control Head -E87- and the actuator function. Refer to Vehicle Diagnostic Tester in the "Guided Fault Finding" function.

- Refer to → Chapter "Bracket for Right Adjustment Motors, Removing and Installing (on a Low or Mid A/C System)"

Removing

- Move the driver seat as far back as possible.

- Turn off the ignition.

- Remove the driver side instrument panel cover. Refer to → Body Interior; Rep. Gr.68; Storage Compartments and Covers; Driver Side Instrument Panel Cover, Removing and Installing.

- Remove the left footwell vent (driver side). Refer to → Chapter "Driver Side Footwell Vent, Removing and Installing".

- Loosen the left air duct above the central tube and push as far as possible to the outer side. Remove the air duct for the left instrument panel vent to do this. Refer to → Chapter "Overview - Air Routing and Air Distribution in Passenger Compartment, Front".

Caution

Caution

A/C system malfunctions in the case of interchanged control motors and/or connectors. Refer to → Chapter "Main Wiring Diagram for A/C System Actuators".

- The adjustment motors and connectors are identical. If they are installed or connected incorrectly, the corresponding doors cannot be properly adapted and/or activated.

- Clearly label the actuators and connectors prior to removal to prevent incorrect installation.

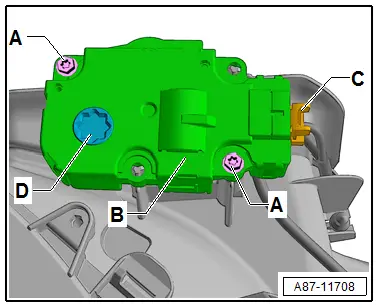

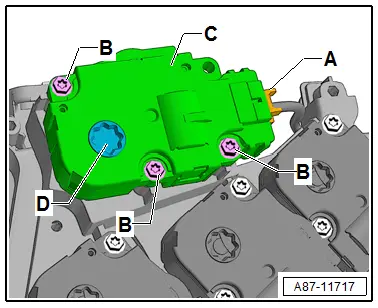

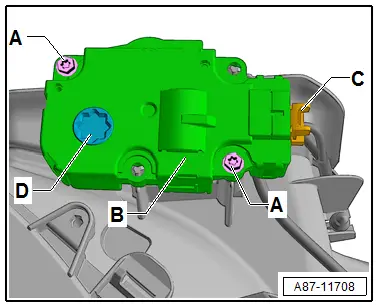

- Label the connector -C- (to prevent a mix up if several connectors are disconnected at the same time).

- Remove the bolts -A-.

- Remove the actuator -B- from the door shaft -D-.

- Disconnect the connector -C-.

Installing

Install in reverse order of removal. Note the following:

Caution

Caution

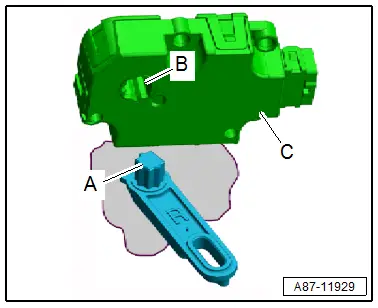

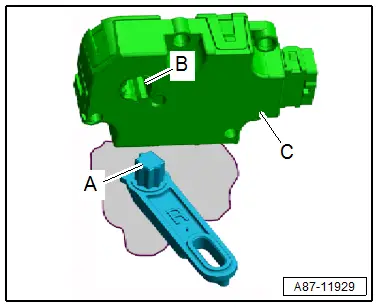

If the mount -B- for the actuator -C- is turned by hand, then the electronics in the actuator can be damaged.

Note

Note

The actuator mount does not have a stop. It turns constantly if the actuator is activated. Therefore, this should not be activated with the adjustment motor removed.

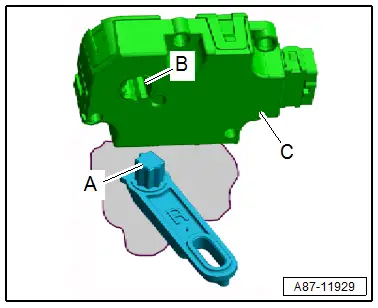

- Check the shaft -A- and the mount -B- for the actuator -C-. They must be properly aligned so that they can be joined.

- Attach the actuator mount -B- to the door shaft -A-.

Note

Note

Check the connection between the actuator mount and the shaft; there must not be any play.

- Connect the connector -C- .

- Tighten the bolts -A-.

- Route the wiring harness to the connector -C- so that it cannot come in contact with any moving parts.

- Perform the basic setting and the output diagnostic test mode of the A/C system. Refer to Vehicle Diagnostic Tester in the "Guided Fault Finding" function.

Note

Note

- In this vehicle, the actuators are equipped with electronics. During the basic setting, a new control motor learns its position on the heater and A/C unit and can then be activated by the Front A/C Display Control Head -E87- (currently all actuators are identical). Refer to Vehicle Diagnostic Tester in the "Guided Fault Finding" function.

- During the basic setting, the actuators are assigned and adapted corresponding to the switching sequence of the wiring. If this sequence does not conform with the specification, the actuators will adapt incorrectly and the door control will be wrong. Refer to → Chapter "Main Wiring Diagram for A/C System Actuators".

- Check the DTC memory on the Front A/C Display Control Head -E87- and erase any displayed malfunctions. Refer to Vehicle Diagnostic Tester in the "Guided Fault Finding" function.

Right Center Vent Motor -V111-, Removing and Installing

Note

Note

- Depending on vehicle equipment, there are different versions of the A/C system for the Audi Q7. Make sure to use the correct version and pay attention to the allocation of different components. Refer to → Chapter "A/C System Versions" and Parts Catalog.

- The Right Center Vent Motor -V111- is only installed on vehicles with a "Mix" or "High" A/C system. On vehicles with a "Low" or "Mid" A/C system, the right door is actuated via the lever and a curved washer from the Right Side Vent Motor -V300-.

- Currently in this vehicle, all actuators are identical in construction. During the basic setting, the actuators are assigned and adapted corresponding to the switching sequence of the wiring. If this sequence does not conform with the specification, the actuators will adapt incorrectly and the door control will be wrong. Refer to → Chapter "Main Wiring Diagram for A/C System Actuators".

- Therefore, perform the basic setting for the A/C system after installation of the adjustment motor. Refer to Vehicle Diagnostic Tester in the "Guided Fault Finding" function.

- Using the "output diagnostic test mode" and "basic setting" functions, the activation of A/C system electrical components can be tested if necessary (for example, allocation test). Refer to Vehicle Diagnostic Tester in the "Guided Fault Finding" function.

- After installing a new actuator, check the activation via the Front A/C Display Control Head -E87- and the actuator function. Refer to Vehicle Diagnostic Tester in the "Guided Fault Finding" function.

- Refer to → Chapter "Bracket for Right Adjustment Motors, Removing and Installing (on a Low or Mid A/C System)"

Removing

- Turn off the ignition.

- Move the front passenger seat as far back as possible.

- Remove the glove compartment. Refer to → Body Interior; Rep. Gr.68; Storage Compartments and Covers; Glove Compartment, Removing and Installing.

- If equipped, remove the air duct for the glove compartment cooling. Refer to → Chapter "Air Guide for Glove Compartment Cooling, Removing and Installing".

Note

Note

On right-hand drive vehicles, move the driver seat to the farthest back position and remove the driver side instrument panel cover. Refer to → Body Interior; Rep. Gr.68; Storage Compartments and Covers; Driver Side Instrument Panel Cover, Removing and Installing.

- Remove the right footwell vent (front passenger side). Refer to → Chapter "Front Passenger Side Footwell Vent, Removing and Installing".

- Loosen the air duct over the central tube and push as far as possible to the outer side.

Caution

Caution

A/C system malfunctions in the case of interchanged control motors and/or connectors. Refer to → Chapter "Main Wiring Diagram for A/C System Actuators".

- The adjustment motors and connectors are identical. If they are installed or connected incorrectly, the corresponding doors cannot be properly adapted and/or activated.

- Clearly label the actuators and connectors prior to removal to prevent incorrect installation.

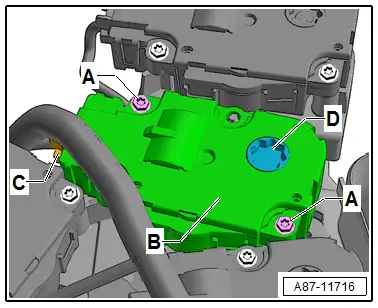

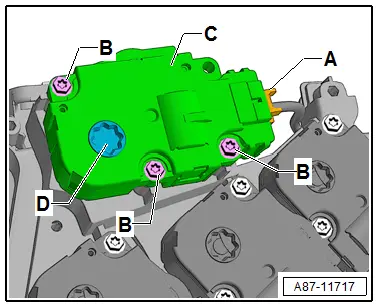

- Label the connector -A- and the actuator -C- (to avoid a mix up in case several connectors are disconnected at the same time).

- Remove the bolts -B-. If necessary, remove the right instrument panel vent air duct from the heater and A/C unit and push slightly to the side.

- Remove the actuator -C- from the shaft -D- for operating the doors.

- Disconnect the connector -A-.

Installing

Install in reverse order of removal. Note the following:

Caution

Caution

If the mount -B- for the actuator -C- is turned by hand, then the electronics in the actuator can be damaged.

Note

Note

The actuator mount does not have a stop. It turns constantly if the actuator is activated. Therefore, this should not be activated with the adjustment motor removed.

- Check the shaft -A- and the mount -B- for the actuator -C-. They must be properly aligned so that they can be joined.

- Attach the actuator mount -B- to the door shaft -A-.

Note

Note

Check the connection between the actuator mount and the shaft; there must not be any play.

- Connect the connector -A-.

- Tighten the bolts -B-.

- Route the wiring harness to the connector -A- so that it cannot come in contact with any moving parts.

- Perform the basic setting and the output diagnostic test mode of the A/C system. Refer to Vehicle Diagnostic Tester in the "Guided Fault Finding" function.

Note

Note

- In this vehicle, the actuators are equipped with electronics. During the basic setting, a new control motor learns its position on the heater and A/C unit and can then be activated by the Front A/C Display Control Head -E87- (currently all actuators are identical). Refer to Vehicle Diagnostic Tester in the "Guided Fault Finding" function.

- During the basic setting, the actuators are assigned and adapted corresponding to the switching sequence of the wiring. If this sequence does not conform with the specification, the actuators will adapt incorrectly and the door control will be wrong. Refer to → Chapter "Main Wiring Diagram for A/C System Actuators".

- Check the DTC memory on the Front A/C Display Control Head -E87- and erase any displayed malfunctions. Refer to Vehicle Diagnostic Tester in the "Guided Fault Finding" function.

Recirculation Door Motor -V113-, Removing and Installing

Note

Note

- Therefore, perform the basic setting for the A/C system after installation of the adjustment motor. Refer to Vehicle Diagnostic Tester in the "Guided Fault Finding" function.

- Using the "output diagnostic test mode" and "basic setting" functions, the activation of A/C system electrical components can be tested if necessary (for example, allocation test). Refer to Vehicle Diagnostic Tester in the "Guided Fault Finding" function.

- Currently in this vehicle, all actuators are identical in construction. During the basic setting, the actuators are assigned and adapted corresponding to the switching sequence of the wiring. If this sequence does not conform with the specification, the actuators will adapt incorrectly and the door control will be wrong. Refer to → Chapter "Main Wiring Diagram for A/C System Actuators".

- After installing a new control motor, check the activation through the Front A/C Display Control Head -E87-, and the function of the actuator (correct position of the recirculation door and the back pressure/fresh air door). Refer to Vehicle Diagnostic Tester in the "Guided Fault Finding" function.

- In the event of problems with moisture in passenger compartment, additionally check recirculation door (must close completely).

Removing

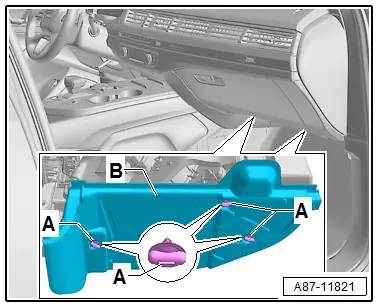

- Move the right front seat (front passenger seat) as far back as possible.

- Turn off the ignition.

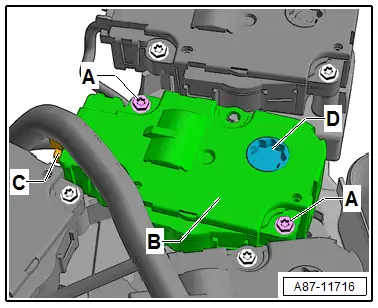

- Remove screw clips -A-.

- Loosen the insulation -B- from the heater and A/C Unit air intake housing and remove.

- Label the connector -C- (to prevent a mix up if several connectors are disconnected at the same time).

- Remove the bolts -A-.

- Remove the actuator -B- from the door shaft -D-.

- Disconnect the connector -C-.

Installing

Install in reverse order of removal. Note the following:

Caution

Caution

If the mount -B- for the actuator -C- is turned by hand, then the electronics in the actuator can be damaged.

Note

Note

The actuator mount does not have a stop. It turns constantly if the actuator is activated. Therefore, this should not be activated with the adjustment motor removed.

- Check the shaft -A- and the mount -B- for the actuator -C-. They must be properly aligned so that they can be joined.

- Attach the actuator mount -B- to the door shaft -A-.

Note

Note

Check the connection between the actuator mount and the shaft; there must not be any play.

- Connect the connector -C- .

- Tighten the bolts -A-.

- Route the wiring harness to the connector -C- so that it cannot come in contact with any moving parts.

- Perform the basic setting and the output diagnostic test mode of the A/C system. Refer to Vehicle Diagnostic Tester in the "Guided Fault Finding" function.

Note

Note

- In this vehicle, the actuators are equipped with electronics. During the basic setting, a new control motor learns its position on the heater and A/C unit and can then be activated by the Front A/C Display Control Head -E87- (currently all actuators are identical). Refer to Vehicle Diagnostic Tester in the "Guided Fault Finding" function.

- During the basic setting, the actuators are assigned and adapted corresponding to the switching sequence of the wiring. If this sequence does not conform with the specification, the actuators will adapt incorrectly and the door control will be wrong. Refer to → Chapter "Main Wiring Diagram for A/C System Actuators".

- Check the DTC memory on the Front A/C Display Control Head -E87- and erase any displayed malfunctions. Refer to Vehicle Diagnostic Tester in the "Guided Fault Finding" function.