Audi Q7: Cylinder Block, Transmission Side

Overview - Cylinder Block, Transmission Side

Note

Note

For assembly work, secure the engine on the Engine and Gearbox Bracket -VAS6095A-. Refer to → Chapter "Engine, Securing to Engine and Transmission Holder".

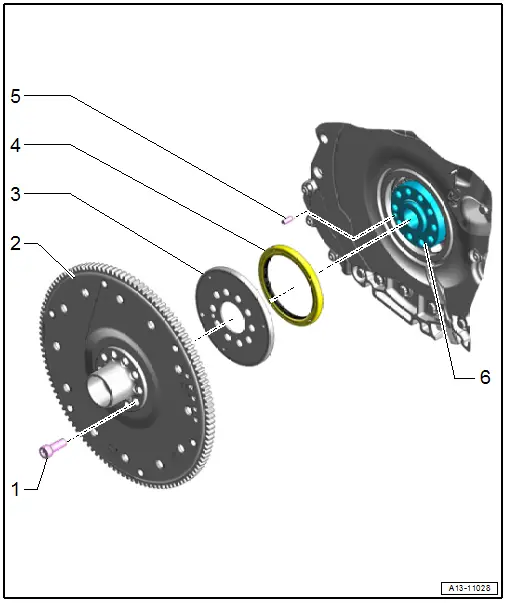

1 - Bolt

- 60 Nm +90º

- Replace after removing

2 - Drive Plate

- With the bearing flange

- Check the contact surfaces on the bearing flange and the torque converter holes for cracks and wear grooves.

- Removing and installing. Refer to → Chapter "Drive Plate, Removing and Installing".

3 - Sensor Wheel

- For the Engine Speed Sensor -G28-

- Removing and installing. Refer to → Chapter "Sensor Wheel, Removing and Installing".

- Checking using the Vehicle Diagnostic Tester. Refer to → Chapter "Sensor Wheel, Checking".

4 - Gasket

- For the crankshaft on the transmission side

- Replacing. Refer to → Chapter "Crankshaft Seal, Replacing, Transmission Side".

5 - Alignment Pin

6 - Crankshaft

Drive Plate, Removing and Installing

Special tools and workshop equipment required

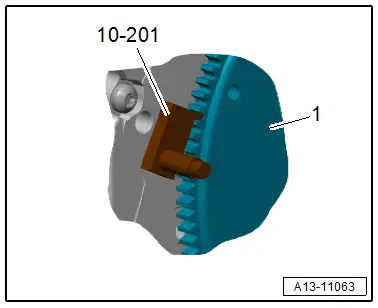

- Counterhold - Flywheel -10-201-

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- Bolts - Drive plate

Removing

- The transmission is removed. Refer to → 8-Speed Automatic Transmission 0D5; Rep. Gr.37; Transmission, Removing and Installing; Transmission, Removing.

- Insert the Counter Hold Tool -10-201- to loosen the bolts.

Caution

Caution

Risk of damaging the outer surface of the bearing flange at the drive plate.

Use an internal multi-point socket with a shaft that is at least 40 mm long to loosen and tighten the drive plate bolts.

- Remove the bolts, drive plate and sensor wheel.

Installing

Install in reverse order of removal and note the following:

Note

Note

Replace the bolts that were tightened with an additional turn after removing them.

- Pay attention to the alignment pin when installing the drive plate.

- Reposition the Counter Hold Tool -10-201- to tighten the bolts.

Tightening Specifications

- Refer to → Chapter "Overview - Cylinder Block, Transmission Side"

Crankshaft Seal, Replacing, Transmission Side

Special tools and workshop equipment required

- Seal Installer - Crankshaft -T10122A-

- Crank Shaft Seal Installer - Guide Piece -T10122/6-

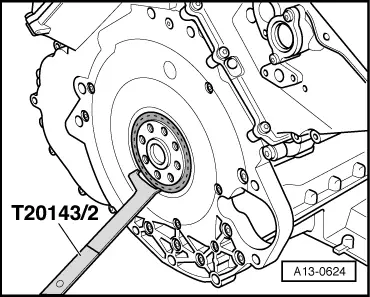

- Puller - Crankshaft/Power Steering Seal -T20143/2-

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- Seal - Crankshaft on the transmission side

Procedure

- The transmission is removed. Refer to → 8-Speed Automatic Transmission 0D5; Rep. Gr.37; Transmission, Removing and Installing; Transmission, Removing.

- Remove the drive plate. Refer to → Chapter "Drive Plate, Removing and Installing".

- Pry out the shaft seal using the Puller - Crankshaft/Power Steering Seal -T20143/2-.

- Clean the contact and sealing surface.

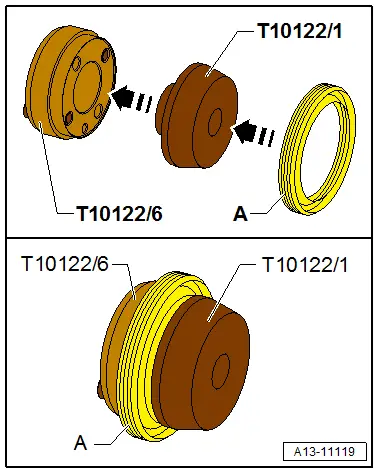

- Attach the Crankshaft Seal Installer Kit - Guide Piece -T10122/1- to the Crankshaft Seal Installer Kit - Guide Piece -T10122/6- and push the shaft seal -A- on the guide piece.

- Remove the Crankshaft Seal Installer Kit - Guide Piece -T10122/1-.

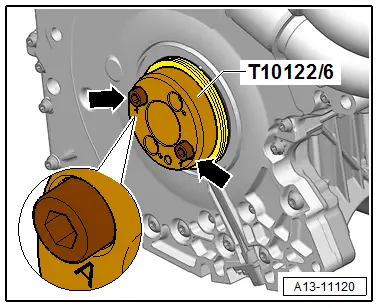

- Position the Crankshaft Seal Installer Kit - Guide Piece -T10122/6- on the crankshaft.

- Attach the Guide Piece to the crankshaft through the mounting points -A- with the bolts -arrows-.

Caution

Caution

There is a risk of leaks due to incorrect assembly.

To prevent the shaft seal sealing lip from rolling onto itself, insert the shaft seal by hand on the crankshaft.

- Push the shaft seal by hand using the Crankshaft Seal Installer Kit - Guide Piece - T10122/6- on the crankshaft.

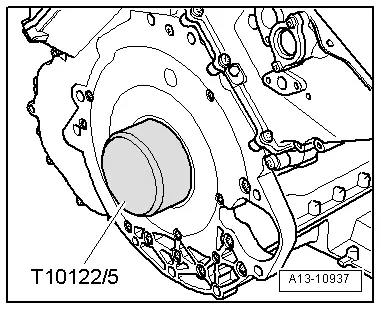

- Press the shaft seal in evenly all around with Crankshaft Seal Installer Kit - Thrust Sleeve -T10122/5-.

- Remove the Crankshaft Seal Installer Kit - Guide Piece -T10122/6-.

- Check the shaft seal as well as its sealing lip for correct seating. If the sealing lip is partially rolled back, repeat the procedure with a new shaft seal.

- Install the drive plate. Refer to → Chapter "Drive Plate, Removing and Installing".