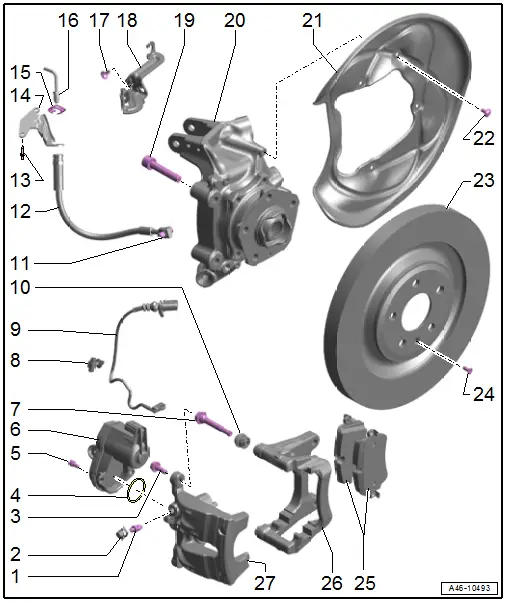

Audi Q7: Overview - Rear Brakes

Audi Q7 (4M) 2016-2025 Workshop Manual / Chassis / Brake System / Mechanical Components / Overview - Rear Brakes

1 - Bleed Screw

- 10 Nm

- Before installing, thinly coat with Assembly Paste -G 052 150 A2-.

2 - Protective Cap

3 - Bolt

- 35 Nm

- Replace after removing

- When loosening and tightening, counterhold at the guide pin

- Self-locking

4 - Gasket

- Replace after removing

5 - Bolt

- 12 Nm

6 - Electro-Mechanical Parking Brake Motor

- Left Parking Brake Motor -V282-

- Right Parking Brake Motor -V283-

- Refer to → Chapter "Left and Right Parking Brake Motor - V282-/-V283-, Removing and Installing"

7 - Guide Pin

- Check ease of movement

8 - Clip

9 - Brake Pad Wear Indicator Wire

- With Left Rear Brake Pad Wear Sensor -G36-/Right Rear Brake Pad Wear Sensor -G37-

- For inner brake pad

- Replace when replacing the brake pads.

- Refer to → Chapter "Brake Pad Wear Indicator Wire, Removing and Installing"

10 - Protective Cap

- Replace if damaged

11 - Banjo Bolt

- 10 Nm +45º

- Permanent with gaskets

- Check for damage

- Replace together with the brake hose

- Clean any corrosion from the sealing surface on the brake caliper

12 - Brake Hose

- Observe correct routing: make sure the brake hose is not blocked, bent or rubbing against the vehicle

- Replace if damaged

- Make sure that lugs are properly seated in grooves in bracket.

13 - Rivet

14 - Bracket

- For the brake line/hose

- On the body

15 - Spring

- Replace if damaged

16 - Brake Line

- Tightening specification, brake line to brake hose, 14 Nm

17 - Bolt

- 8 Nm

18 - Bracket

- For brake hose

19 - Bolt

- 100 Nm +90º

- Replace after removing

- Self-locking

20 - Wheel Bearing Housing

21 - Brake Shield

- Refer to → Chapter "Brake Shield, Removing and Installing"

22 - Bolt

- 10 Nm

23 - Brake Rotor

- Do not use excessive force to separate the brake rotor from the wheel hub. Use rust remover, if necessary, otherwise the brake rotor could be damaged.

- Replace on both sides of axle if worn.

- Refer to → Chapter "Brake Rotor, Removing and Installing"

24 - Bolt

- 10 Nm

25 - Brake Pads

- Check the pad thickness.

- Refer to → Chapter "Brake Pads, Removing and Installing"

- Always replace on both axles.

- Installation position. Refer to → Fig. "Brake Pads Installation Position".

26 - Brake Carrier

- Delivered as an assembled replacement part with sufficient grease on the guide pins

- Refer to → Chapter "Brake Carrier, Removing and Installing"

- Clean the contact surfaces for the brake pads and thinly coat with Lithium Grease -G 052 150 A2-

27 - Brake Caliper

- Refer to → Chapter "Brake Caliper, Removing and Installing"

- Refer to → Chapter "Brake Caliper, Replacing"

- After servicing or replacing perform "Guided Fault Finding". Refer to Vehicle Diagnostic Tester.

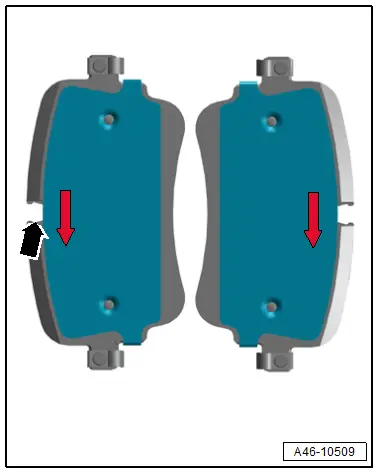

Brake Pads Installation Position

Version 1:

- In installed position, the arrow on the backing plate of the actual brake pad must point downward

Note

Note

- The layout of the arrow is different depending on the manufacturer.

- The contact of the brake pad wear indicator is inserted in the opening -arrow- of the inner brake pad.

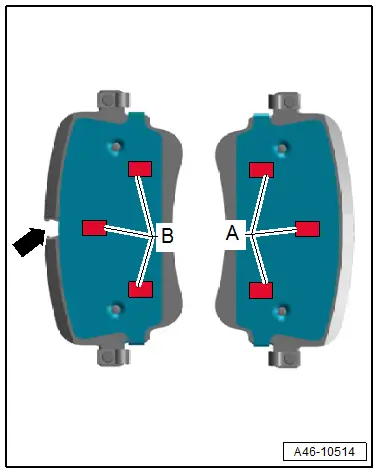

Version 2:

- Pay attention to the labeling on the backing plate of the brake pads.

A - Outside

B - Inner

Note

Note

Additionally the inner brake pad has an opening -arrow- for the contact of the brake pad wear indicator.