Audi Q7: Rear Brake Pads, Removing and Installing

Special tools and workshop equipment required

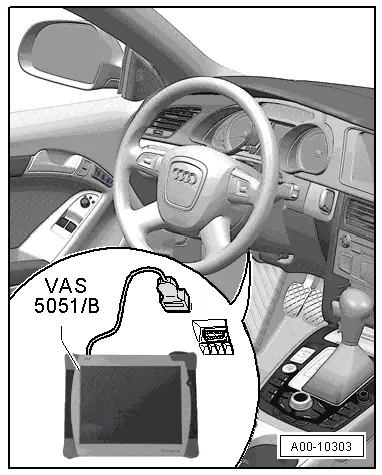

- Vehicle Diagnostic Tester

- Torque Wrench 1331 5-50Nm -VAG1331-

- Piston Resetting Tool -T10145-

- Lithium Grease -G 052 150 A2-. Refer to the Parts Catalog.

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- Brake Pad Wear Indicator Wire - Replace when pads are replaced.

- Brake Pad Retaining Plate - Replace when pads are replaced.

- Brake Pad Spring - Replace when pads are replaced.

Removing

- Loosen the parking brake.

- Switch off the ignition.

Note

Note

- Label the brake pads that will be used again when removing. Install in the same position, otherwise the braking effect will be uneven.

- Do not disconnect the connectors from the parking brake motors.

- Remove the rear wheel. Refer to → Suspension, Wheels, Steering; Rep. Gr.44; Wheels and Tires.

Note

Note

If the brake pads are replaced, use the Vehicle Diagnostic Tester to press back the parking brake motor.

- Drive back the parking brake motor:

- Connect the Vehicle Diagnostic Tester to the diagnostic connection on the vehicle with the ignition switched off.

- Switch the ignition on.

- Select diagnostic and start.

- Select the Test plan tab.

- Select Individual tests... and select the following tree structures one after the other:

- Suspension

- Brake System

- 01 - OBD-capable systems

- 03 - ABS Control Module J104 integrated parking brake

- 03 - Electric parking brake functions

- 03 - Removing the brake pads

- Start the selected program and follow the instructions in the display of the Vehicle Diagnostic Tester.

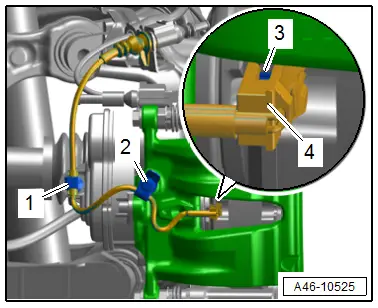

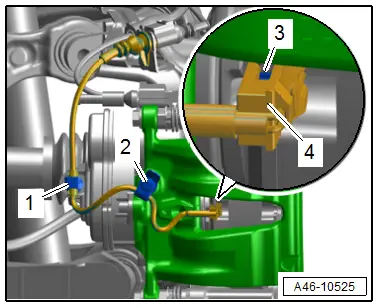

- Free up the wire, to do so open the protective cap -2- from the bleed screw and open the clip -1-.

- Carefully remove the contact -4- for the brake pad wear indicator using pliers at the same time pay attention to the clip -3-.

Note

Note

If the clips go missing, the brake pad wear indicator wire must be replaced.

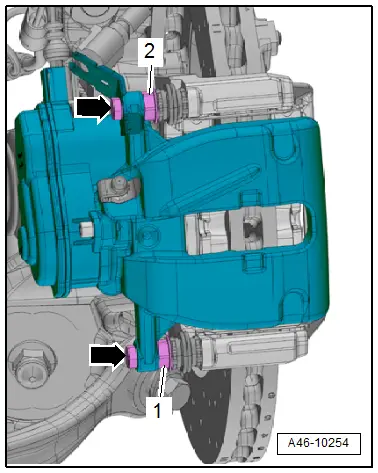

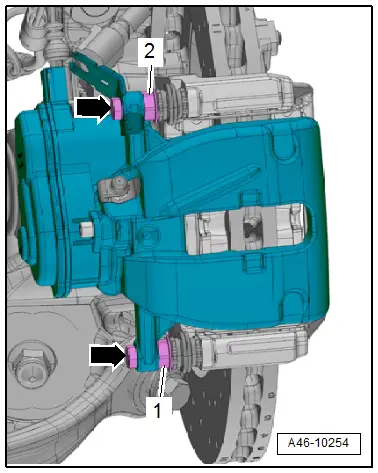

- Remove the bolts -arrows- by counterholding the guide pins -1 and 2-.

- Remove the brake caliper and guide the brake pad wear indicator wire out at the same time.

Caution

Caution

Danger of damaging the brake hose.

- Do not let the brake caliper hang on the brake hose. Do not support the weight with the brake hose.

- Replace the brake hose if damaged.

Risk of damaging the brake caliper piston.

Do not operate the brakes or the electro-mechanical parking brake when the brake caliper is removed.

- Hang the brake caliper using a suitable wire.

- Remove the brake pads.

Installing

Install in reverse order of removal and note the following:

- When the brake pads are replaced, check the brake rotors for wear and damage:

- Brake rotor wear limit. Refer to → Chapter "Technical Data".

Note

Note

- Always replace brake pads on the same axle at the same time.

- When installing new brake pads use the repair kit and new brake pad wear indicator wire.

- Replace the brake caliper bolts after disassembly.

WARNING

WARNING

Health Risk.

Do not blow out brake system with compressed air.

Note

Note

- Use only mineral spirits to clean the brake caliper.

- Check the brake caliper piston protective caps for damage and install the complete repair kit, if necessary. Refer to → Chapter "Brake Caliper Piston, Removing and Installing".

Caution

Caution

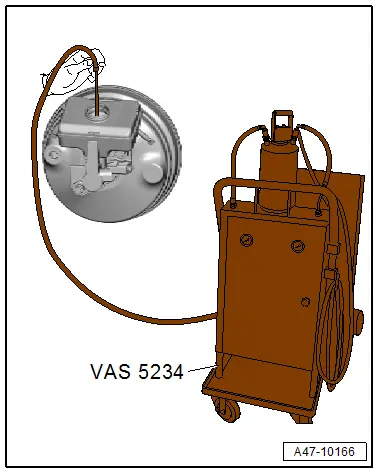

Danger of contamination and paint damage from escaping brake fluid.

- If the brake pads are worn out and unnecessary brake fluid was filled, the brake fluid may overflow, when the brake caliper pistons in the brake cylinders are pressed back.

- Check the brake fluid level before pressing back the brake caliper pistons. If there is brake fluid up to the "MAX" mark, some brake fluid will need to be extracted.

- Use the Brake Charger/Bleeder Unit -VAS5234- to extract brake fluid from brake fluid reservoir.

- Use the Piston Resetting Tool -T10145- to completely press back the brake caliper piston.

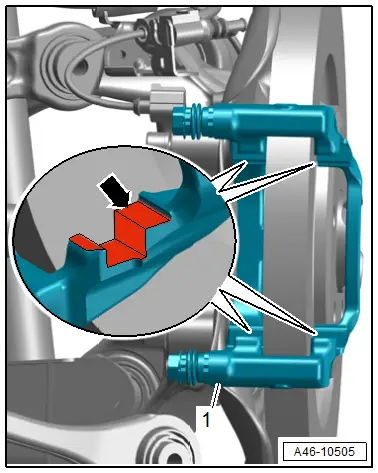

- Clean the brake carrier -1- on the brake pad spring contact surfaces -arrow- and thinly coat them with lithium grease.

- If re-using, install the marked brake pads in the same location.

- Insert brake pads in brake carrier.

- Push the brake caliper over the installed brake pads.

Note

Note

- Make sure that the wire and brake hose are routed correctly.

- Make sure the brake hose is not blocked, bent, twisted or rubbing against the vehicle.

- Tighten the new brake caliper bolts -arrows- by counterholding the guide pins -1 and 2-.

Note

Note

- Check the brake pad wear indicator contact for damage and if required replace.

- Make sure that the brake pad wear indicator contact fits correctly in the brake pad.

- If the clips go missing, the brake pad wear indicator wire must be replaced.

- Insert the contact -4- for the brake pad wear indicator with the clip -3- until it engages in the inner brake pad.

- Secure the brake pad wear indicator wire with the protective cap -2- and the clip -1-, as shown.

- With the vehicle stationary, firmly press the brake pedal several times so that the brake pads in the operating condition properly set in their respective position.

- Drive the parking brake motor out. Refer to Vehicle Diagnostic Tester by following the instructions in the display.

WARNING

WARNING

Risk of accident!

- With the vehicle stationary, firmly press the brake pedal several times so that the brake pads in the operating condition properly set in their respective position.

- Make sure the brakes are working correctly before driving the vehicle for the first time.

Tightening Specifications

- Refer to → Chapter "Overview - Rear Brakes"

- Refer to → Suspension, Wheels, Steering; Rep. Gr.44; Wheels and Tires.