Audi Q7: Stabilizer Bar

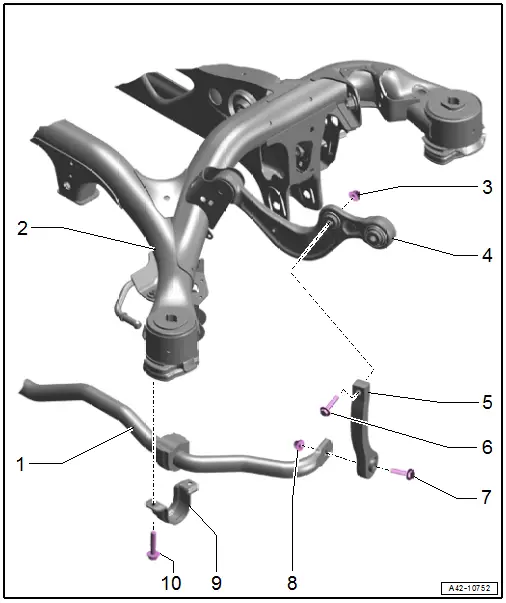

Overview - Stabilizer Bar

1 - Stabilizer Bar

- Removing and installing. Refer to → Chapter "Stabilizer Bar, Removing and Installing".

- With rubber bushing

- The bonded rubber bushing cannot be replaced separately

2 - Subframe

3 - Nut

- Replace after removing

4 - Transverse Link, Upper Front

5 - Coupling Rod

- Removing and installing. Refer to → Chapter "Coupling Rod, Removing and Installing".

6 - Bolt

- 40 Nm +180º

- Replace after removing

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing at Standard Vehicle Height, Lifting Vehicles with Air Suspension".

7 - Bolt

- 40 Nm +180º

- Replace after removing

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing at Standard Vehicle Height, Lifting Vehicles with Air Suspension".

8 - Nut

- Replace after removing

9 - Clamp

10 - Bolt

- 25 Nm +90º

- Replace after removing

Stabilizer Bar, Removing and Installing

Special tools and workshop equipment required

- Torque Wrench 1331 5-50Nm -VAG1331-

- Socket Bit XZN 10 -T10501-

Removing

Before starting work:

- Versions with coil springs: determine the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring".

- Versions with air suspension: determine the standard vehicle height. Refer to → Chapter "Wheel Bearing at Standard Vehicle Height, Lifting Vehicles with Air Suspension".

- Remove the right diagonal brace. Refer to → Body Exterior; Rep. Gr.66; Underbody Trim Panel.

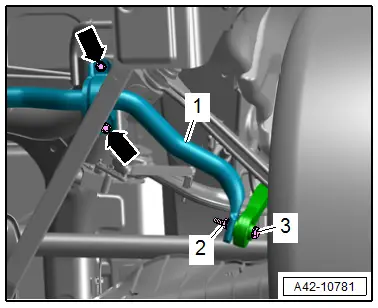

- Remove left and right bolts -arrow- and nut -2-.

- Remove the bolt -3- and stabilizer bar -1-.

Installing

Install in reverse order of removal and note the following:

- Install the threaded connections for the stabilizer bar only until stop but do not yet tighten.

Note

Note

Bonded rubber bushings have a limited range of motion. Only tighten suspension bolts when vehicle is in curb weight position or at standard vehicle height.

- Lifting the wheel bearing in curb weight position (refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring") or at standard vehicle height (refer to → Chapter "Wheel Bearing at Standard Vehicle Height, Lifting Vehicles with Air Suspension").

Tightening Specifications

- Refer to → Chapter "Overview - Stabilizer Bar"

Coupling Rod, Removing and Installing

Special tools and workshop equipment required

- Torque Wrench 1331 5-50Nm -VAG1331-

Removing

Before starting work:

- Versions with coil springs: determine the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring".

- Versions with air suspension: determine the standard vehicle height. Refer to → Chapter "Wheel Bearing at Standard Vehicle Height, Lifting Vehicles with Air Suspension".

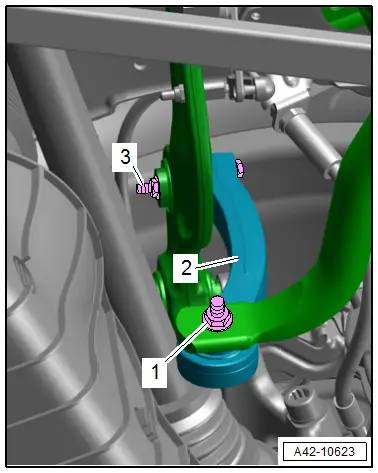

- Disconnect the connectors -1 and 3- and remove the coupling rod -2-.

Installing

Install in reverse order of removal and note the following:

- Install the threaded connections for the coupling rod only until stop but do not yet tighten.

Note

Note

Bonded rubber bushings have a limited range of motion. Only tighten suspension bolts when vehicle is in curb weight position or at standard vehicle height.

- Lifting the wheel bearing in curb weight position (refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring") or at standard vehicle height (refer to → Chapter "Wheel Bearing at Standard Vehicle Height, Lifting Vehicles with Air Suspension").

Tightening Specifications

- Refer to → Chapter "Overview - Stabilizer Bar"