Audi Q7: Subframe Mount

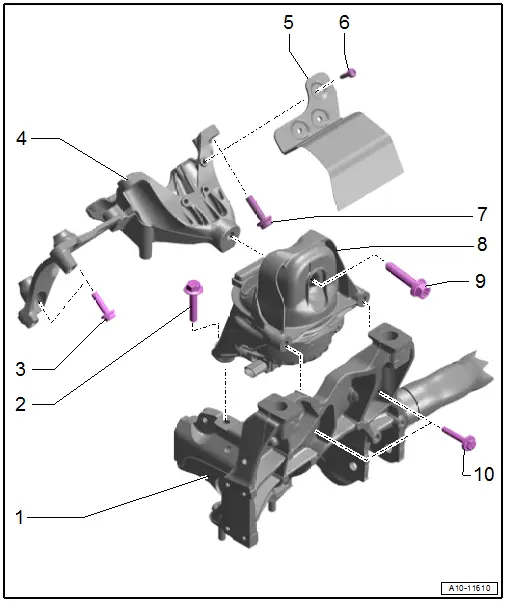

Overview - Subframe Mount

Engine Mount

1 - Subframe

2 - Bolt

- 55 Nm

3 - Bolt

- 20 Nm

- M8

4 - Engine Support

- Removing and installing. Refer to → Chapter "Engine Support, Removing and Installing".

5 - Heat Shield

6 - Bolt

- 10 Nm

7 - Bolt

- 55 Nm

- M10

8 - Engine Mount

- With

- Left Electrohydraulic Engine Mount Solenoid Valve -N144-

- Right Electrohydraulic Engine Mount Solenoid Valve -N145-

- Removing and installing. Refer to → Chapter "Engine Mount, Removing and Installing".

9 - Bolt

- 90 Nm +90º

- Replace after removing

10 - Bolt

- 30 Nm

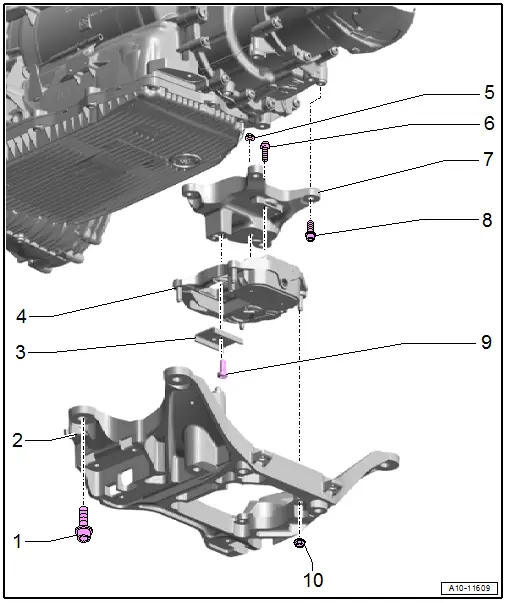

Transmission Mount

1 - Bolt

- Tightening specification. Refer to → 8-Speed Automatic Transmission; Rep. Gr.37; Subframe Mount; Overview - Subframe Mount.

2 - Tunnel Crossmember

- Removing and installing. Refer to → 8-Speed Automatic Transmission; Rep. Gr.37; Subframe Mount; Overview - Subframe Mount.

3 - Stop

- For the transmission mount

4 - Transmission Mount

- Removing and installing. Refer to → Chapter "Transmission Mount, Removing and Installing".

5 - Nut

- Tightening specification. Refer to → 8-Speed Automatic Transmission; Rep. Gr.37; Subframe Mount; Overview - Subframe Mount.

6 - Bolt

- Tightening specification. Refer to → 8-Speed Automatic Transmission; Rep. Gr.37; Subframe Mount; Overview - Subframe Mount.

7 - Transmission Support

- Removing and installing. Refer to → Chapter "Transmission Mount, Removing and Installing".

8, 9 - Bolt

- Tightening specification. Refer to → 8-Speed Automatic Transmission; Rep. Gr.37; Subframe Mount; Overview - Subframe Mount.

10 - Nut

- Tightening specification. Refer to → 8-Speed Automatic Transmission; Rep. Gr.37; Subframe Mount; Overview - Subframe Mount.

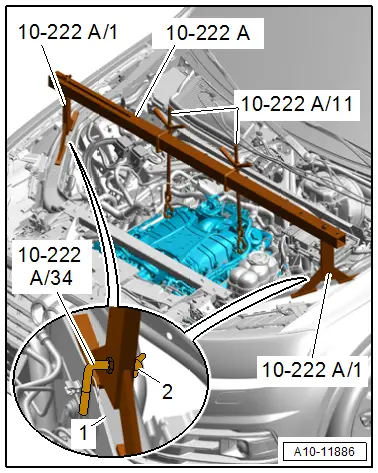

Engine, Supporting in Installation Position

Special tools and workshop equipment required

- Engine Support Bridge -10-222A-

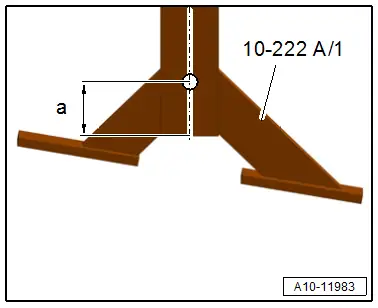

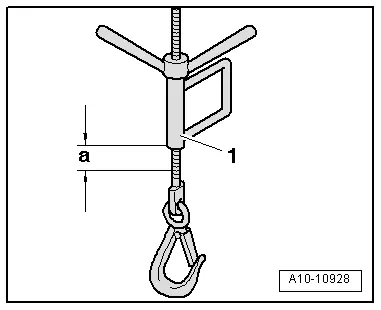

Tools, Preparing

- Make a 11 mm diameter hole in both Engine Support Bridge - Engine Bracket -10-222A/1- as shown.

- Dimension -a- = 30 mm

Procedure

WARNING

WARNING

Risk of accident due to the engine weight shifting.

The transmission and tunnel crossmember must be installed for the support procedure described in the following.

- Remove the engine cover. Refer to → Chapter "Engine Cover, Removing and Installing".

- Remove the left and right headlamp cover. Refer to → Body Exterior; Rep. Gr.50; Lock Carrier; Overview - Lock Carrier.

- Position the Engine Support Bridge -10-222A- on the left and right longitudinal member as shown.

- Tighten the Engine Support Bridge - Adapters -10-222A/34- on the Engine Support Bridge - Engine Bracket -10-222A/1- with the nut -2- at the same time the adapter must engage in the longitudinal member -1- as shown.

- Attach the spindles Engine Support Bridge - Spindle -10-222A/11- to the left and right engine lifting eyes.

- Slightly pretension the engine with the spindle, do not lift.

Assembling

Assemble in the reverse order of removal. Note the following:

- Install the engine cover. Refer to → Chapter "Engine Cover, Removing and Installing".

Tightening Specifications

- Refer to → Chapter "Overview - Subframe Mount"

- Refer to → Body Exterior; Rep. Gr.50; Lock Carrier; Overview - Lock Carrier.

Engine Mount, Removing and Installing

Left Engine Mount, Removing and Installing

Removing

- Support the engine in the installation position. Refer to → Chapter "Engine, Supporting in Installation Position".

- Remove the front noise insulation. Refer to → Body Exterior; Rep. Gr.66; Noise Insulation; Noise Insulation, Removing and Installing.

- Remove the left front section of the wheel housing liner. Refer to → Body Exterior; Rep. Gr.66; Wheel Housing Liner; Front Wheel Housing Liner, Removing and Installing.

- Remove the ribbed belt from the A/C compressor belt pulley. Refer to → Chapter "Ribbed Belt, Removing and Installing, Sub-Assembly Ribbed Belt".

- Remove the lower left longitudinal member. Refer to → Body Exterior; Rep. Gr.50; Lock Carrier; Overview - Lock Carrier.

- Remove the A/C compressor from the bracket and tie it up on the left side. Refer to → Heating, Ventilation and Air Conditioning; Rep. Gr.87; A/C Compressor; A/C Compressor, Removing and Installing at Bracket.

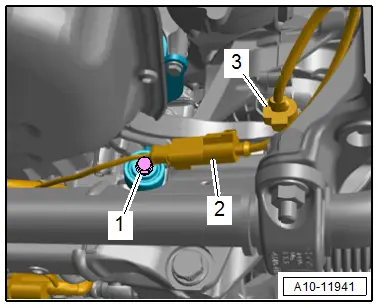

- Remove and disconnect the connector -3- for the Left Electrohydraulic Engine Mount Solenoid Valve -N144- from the bracket.

- Remove the connector -2- from the bracket, disconnect it and free up the wire.

Note

Note

Ignore -1-.

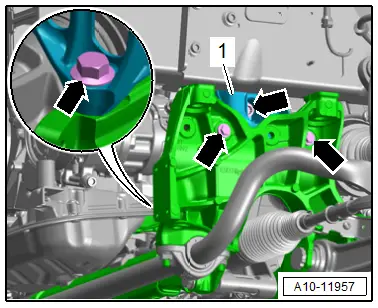

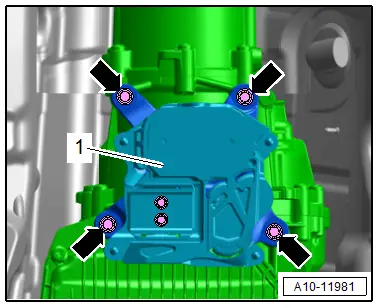

- Remove the bolts -arrows- for the engine mount -1-.

- Lift the engine using the Engine Support Bridge - Spindle -10-222A/11--1- to dimension -a-.

- Dimension -a- = approximately 15 mm.

- Remove the engine mount.

Installing

Install in reverse order of removal and note the following:

Note

Note

Replace the bolts that were tightened with an additional turn after removing them.

- Install the ribbed belt. Refer to → Chapter "Ribbed Belt, Removing and Installing, Sub-Assembly Ribbed Belt".

Tightening Specifications

- Refer to → Chapter "Overview - Subframe Mount"

- Refer to → Heating, Ventilation and Air Conditioning; Rep. Gr.87; A/C Compressor; Overview - A/C Compressor Power Unit.

- Refer to → Body Exterior; Rep. Gr.50; Lock Carrier; Overview - Lock Carrier.

- Refer to → Body Exterior; Rep. Gr.66; Wheel Housing Liner; Overview - Front Wheel Housing Liner.

- Refer to → Body Exterior; Rep. Gr.66; Noise Insulation; Overview - Noise Insulation.

Right Engine Mount, Removing and Installing

Removing

- Lower the subframe. Refer to → Suspension, Wheels, Steering; Rep. Gr.40; Subframe; Subframe, Lowering.

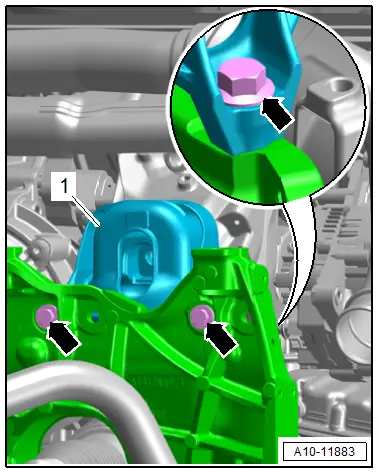

- Remove the bolts -arrows- and right engine mount -1-.

Installing

Install in reverse order of removal and note the following:

Note

Note

Replace the bolts that were tightened with an additional turn after removing them.

- Install the subframe. Refer to → Suspension, Wheels, Steering; Rep. Gr.40; Subframe; Subframe, Lowering.

Tightening Specifications

- Refer to → Chapter "Overview - Subframe Mount"

Transmission Mount, Removing and Installing

Transmission Support with Transmission Mount, Removing and Installing

Removing

- Remove the tunnel crossmember. Refer to → 8-Speed Automatic Transmission; Rep. Gr.37; Subframe Mount; Overview - Subframe Mount.

- Remove the bolts -arrows- and remove the transmission support with the transmission mount from the transmission.

Installing

Install in reverse order of removal.

Tightening Specifications

- Refer to → 8-Speed Automatic Transmission; Rep. Gr.37; Subframe Mount; Overview - Subframe Mount.

Transmission Mount, Removing and Installing

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- Bolts - Transmission mount stop

Removing

- Remove the transmission support with the transmission mount. Refer to → Chapter "Transmission Support with Transmission Mount, Removing and Installing".

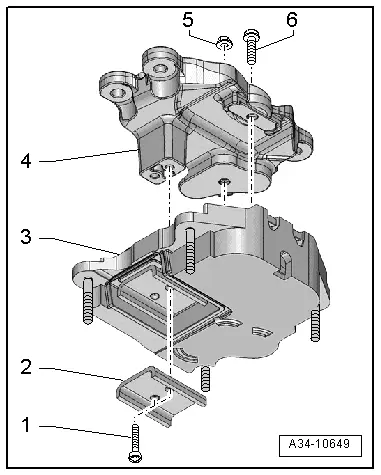

- Remove the bolts -1- and remove the stop -2- for the transmission mount.

- Remove the nut -5- and the bolt -6- and remove the transmission mount -3- from the transmission support -4-.

Installing

Install in reverse order of removal and note the following:

- Place the transmission support -4- on the transmission mount -3-.

- Tighten the nut -5- and bolt -6- hand-tight.

- Tighten the bolts -1- for the stop -2-.

- Tighten the nut -5- and bolt -6-.

- Install the transmission support with the transmission mount. Refer to → Chapter "Transmission Support with Transmission Mount, Removing and Installing".

Tightening Specifications

- Refer to → 8-Speed Automatic Transmission; Rep. Gr.37; Subframe Mount; Overview - Subframe Mount.