Audi Q7: Supercharger, Securing on Engine and Transmission Holder

Supercharger, Securing to Engine/Transmission Holder for Repair Work

Note

Note

The openings on the bottom of the supercharger housing should make it possible to see and reach the charge air cooler.

Special tools and workshop equipment required

- Engine and Gearbox Bracket -VAS6095A-

- Gearbox Support -T40206- with -T40206/1-

- Support -T40304-

Procedure

- Supercharger removed. Refer to → Chapter "Supercharger, Removing and Installing".

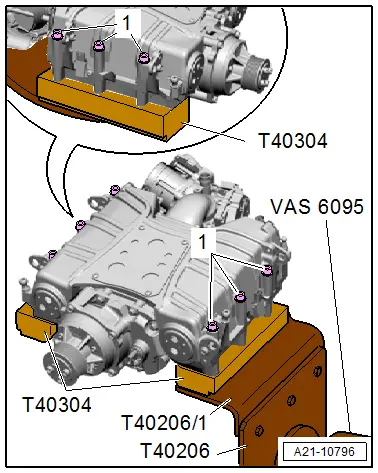

- Insert the Gearbox Support -T40206- with -T40206/1- in the Engine and Gearbox Bracket -VAS6095A-.

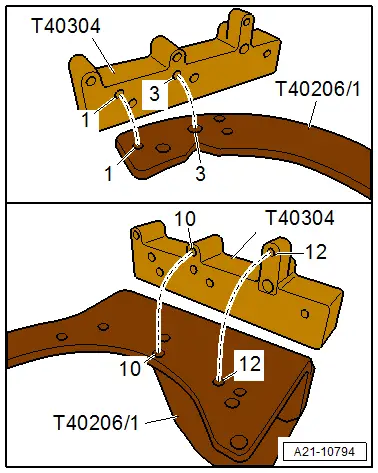

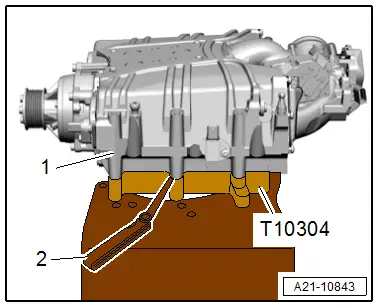

- Install the Supercharger Module Support -T40304- next loosely on the -T40206/1- while doing so pay attention to the allocation of the holes -1, 3, 10 and 12- on the mount and the Gearbox Support -T40206-.

- Place the supercharger on the Support -T40304- as shown in the illustration.

- It is possible to see and reach the charge air cooler through the openings on the bottom inside the supercharger housing.

- Tighten the bolts -1- evenly on the left and the right diagonally hand-tight.

- Tighten the Support -T40304- to 21 Nm on the -T40206/1-.

- Tighten the left and right bolts -1- diagonally to 21 Nm.

Supercharger, Securing to Engine/Transmission Holder for Leak Test

Note

Note

The seals on the Supercharger Module Support -T40304- should seal off the openings inside the compressor housing during the leakage test.

Special tools and workshop equipment required

- Engine and Gearbox Bracket -VAS6095A-

- Gearbox Support -T40206- with -T40206/1-

- Support -T40304-

Procedure

- Supercharger removed. Refer to → Chapter "Supercharger, Removing and Installing".

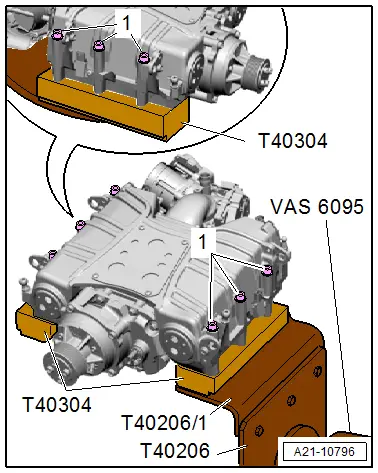

- Insert the Gearbox Support -T40206- with -T40206/1- in the Engine and Gearbox Bracket -VAS6095A-.

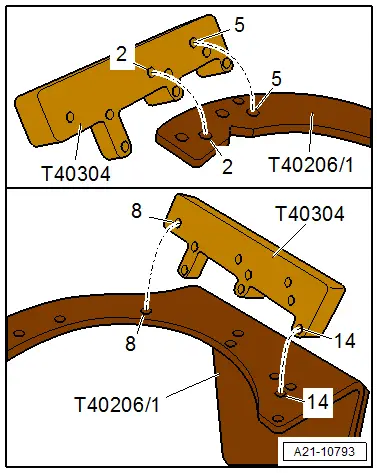

- Install the Support -T40304- next loosely on the -T40206/1- while doing so pay attention to the allocation of the holes -2, 5, 8 and 14- on the mount and the Gearbox Support -T40206-.

- Place the supercharger on the Support -T40304- as shown in the illustration.

- The seals on the supports seal off the openings in the supercharger housing.

- Lightly tighten the bolts -1- evenly on the left and the right diagonally hand-tight.

- Tighten the Support -T40304- to 21 Nm on the -T40206/1-.

- Check that the bolts are tightened evenly with the feeler gauge -2- and adjust if required.

- A uniform gap must be all around between the supercharger -1- and the Support -T40304-.

- Maximum gap dimension tolerance = 0.2 mm

Turbocharger Speed Sensor 1 -G688-, Removing and Installing

Removing

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- O-ring - Turbocharger speed sensor 1

- Remove the engine cover. Refer to → Chapter "Engine Cover, Removing and Installing".

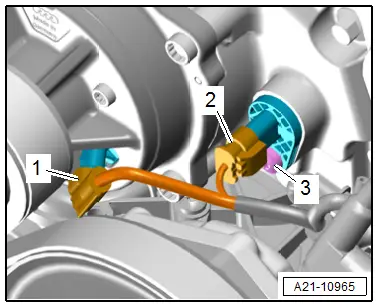

- Disconnect the connector -2-.

- Remove the bolt -3- and the Turbocharger Speed Sensor 1 -G688-.

Note

Note

Ignore -1-.

Installing

Install in reverse order of removal and note the following:

Note

Note

Replace the seal.

- Install the engine cover. Refer to → Chapter "Engine Cover, Removing and Installing".

Tightening Specifications

- Refer to → Chapter "Overview - Supercharger"