Audi Q7: Air Line, Servicing

Note

Note

- Both rear axle air lines (blue and black) are completely replaced if there is a damage claim. The repair of a damaged line is not permitted.

- The front axle and pressure reservoir air lines are routed in the wiring harness and can be repaired.

Special tools and workshop equipment required

- Torque Wrench 1783 - 2-10Nm -VAG1783-

- Torque Wrench 1783 - Open Jaw - 10mm -VAG1783/1-

- Hose Cutting Pliers -VAS6228-

- Air line repair kit. Refer to the Parts Catalog.

Repair 1

- The damaged point of the air line in the wiring harness is not larger than the coupling itself and is not located in a bend of the line routing.

- Free up the corresponding air line from the wiring harness.

- Remove the damaged location.

- Connect the ends of the original line with a coupling from the repair kit.

- Rebundle the wiring harness after servicing.

Repair 2

- The damaged point of an air line in the wiring harness is larger than the coupling itself.

- Open the wiring harness at the damaged location.

- Remove the faulty section of the air line.

- Starting at the solenoid valve block, suspension strut or pressure reservoir route the repair piece parallel to the original wiring harness.

- Connect the ends of the lines with a coupling from the repair kit.

Note

Note

To prevent leaks, the air line in front of and behind the coupling must run straight to a length of 100 mm.

Procedure

Note

Note

- For each line a maximum of two repairs is permitted.

- For a connected wiring harnesses only one repair location each is permitted.

- The position of the repair location must be documented and supplied in the vehicle.

- Clean separation point area before disconnecting air line connector.

- Contaminants entering the lines can lead to system malfunction.

- Clean the area on the connecting piece on the corresponding separation point. Refer to → Chapter "Overview - Air Lines" for the separation point overview.

- Cut through the air line at a right angle at the connector area using Hose Cutting Pliers -VAS6228-.

- Remove connector piece and air line.

- Mark ends of air line in the vehicle and both ends of new air line with a waterproof pen.

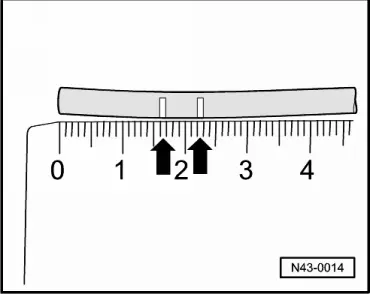

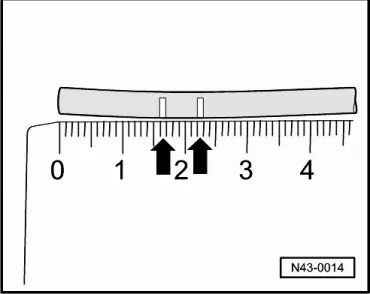

- With "17 mm" or "22 mm" marks, it is checked whether the connector piece is inserted far enough in air line.

- Place the foam rubber on both line.

- Install a new line connector.

Note

Note

Connector pieces in line connector are already tightened to proper torque. Air lines only have to be connected.

- Remove transport protection cap.

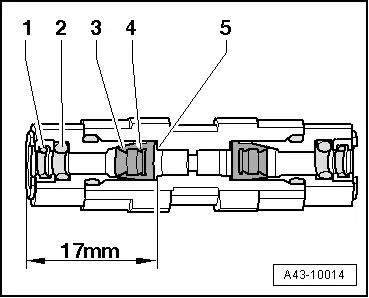

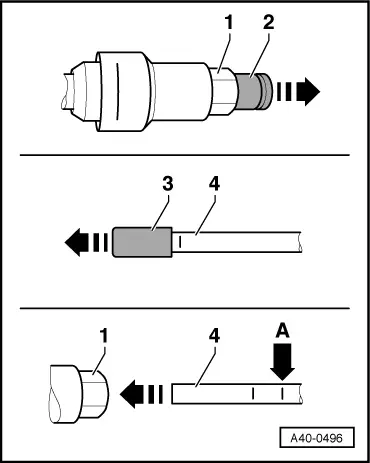

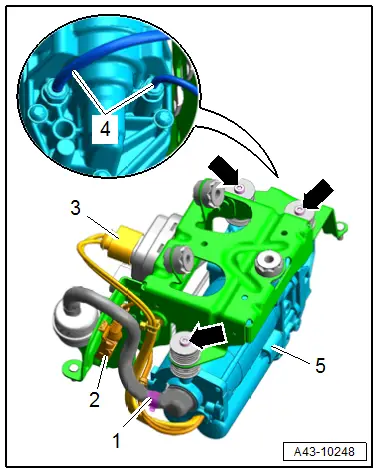

- Push the old air line through the sealing rings -1 and 2-.

- Then slide the air line with some force through edges -3 and 4- of cutting rings as far as stop -5- in line connector.

- Push the foam rubber on the connecting pieces.

- Repeat the procedure with the new air line.

- Connecting piece, replacing. Refer to → Chapter "Connecting Piece, Replacing".

Separating Point: Air Line for the Left Front Air Spring

- Loosen the original air line -4- from the wiring harness -1-.

- Surround the wiring harness properly.

- Service the air line.

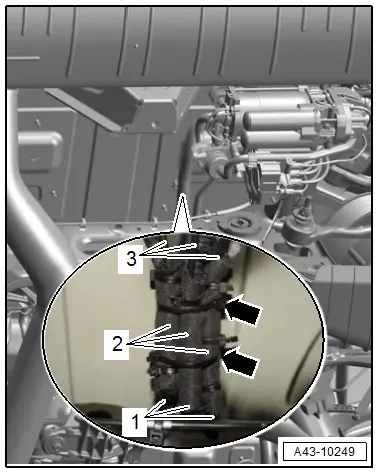

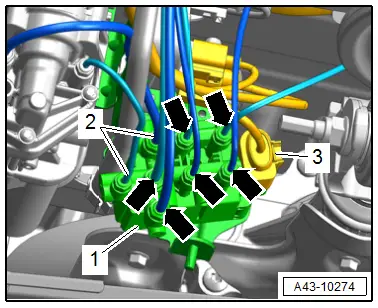

- Attach the wiring connector -3- and the new air line -2- to the wiring harness with cable ties -arrows-.

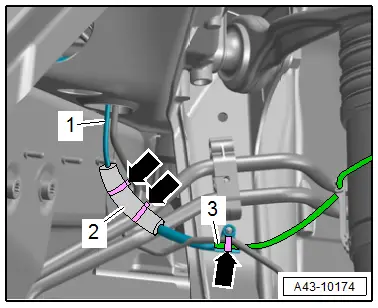

Separating Point: Air Line for the Right Front Air Spring

- Service the air line -1-.

- Secure the coated wiring connector -2- and new air line -3- with cable ties -arrows- on the brake line.

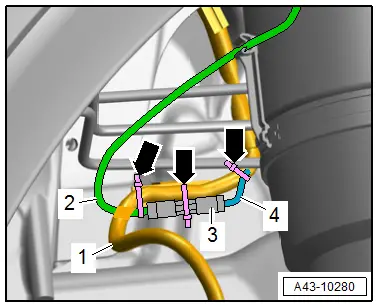

Rear Air Line and Front Air Spring Separating Point

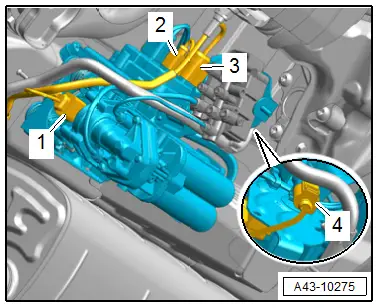

- Loosen the original air lines -1- from the wiring harness.

- Surround the wiring harness properly.

- Service the air line.

- Attach the wiring connector -2- and the new air lines -3- to the wiring harness with cable ties -arrows-.

Note

Note

A repair with multiple repair locations is shown.

Tightening Specifications

- -Item 5-

Connecting Piece, Replacing

Special tools and workshop equipment required

- Torque Wrench 1783 - 2-10Nm -VAG1783-

- Torque Wrench 1783 - Open Jaw - 10mm -VAG1783/1-

- Hose Cutting Pliers -VAS6228-

Procedure

If connector leaks, if air line is long enough, it can be shortened by 10 mm and a new connecting piece installed.

Note

Note

- Replace the connecting piece after removing

- Clean separation point area before disconnecting air line connector.

- Contaminants entering the lines can lead to system malfunction.

- Remove connector piece and air line.

- Remove cutting ring from air line.

- Using the Hose Cutting Pliers -VAS6228-, cut the air line behind the pressure point from cutting ring at right angle.

- Mark the air line ends of the air line in the vehicle with a waterproof felt-tip marker.

Note

Note

With 17 mm or 22 mm marks, it is checked whether the connector piece is inserted far enough in air line.

- Install new connecting piece by hand and tighten.

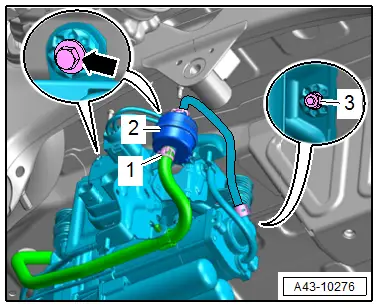

- Only remove the transport protection caps -2 and 3- after connecting air line -4-.

- Route the air line with the applicable clips/grommets in the vehicle. If necessary replace the cut cable tie.

- Remove the transport protection caps.

- Slide air line -4- in with some force as far as stop in connector piece -1-.

- Air lines are installed correctly when only one of the two markings is visible -arrow A-.

Tightening Specifications

- Refer to → Chapter "Overview - Air Lines"

Air Supply Unit, Removing and Installing

Air Supply Unit with Bracket, Removing and Installing

Special tools and workshop equipment required

- Torque Wrench 1783 - 2-10Nm -VAG1783-

- Torque Wrench 1783 - Open Jaw - 10mm -VAG1783/1-

Removing

Note

Note

Follow the guidelines for clean working conditions. Refer to → Chapter "Guidelines for Clean Working Conditions".

- Vent the system. Refer to → Chapter "Air Suspension System, Filling and Bleeding".

- Switch off the ignition.

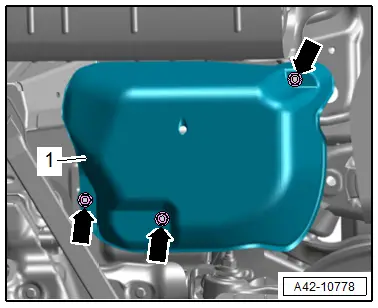

- Remove the nuts -arrows-, and remove the cover -1- for the air supply unit.

- Disconnect the connector -3- from the solenoid valve -1-.

- Remove the air lines -arrows- and protect them from dirt.

Note

Note

Ignore -2-.

- Disconnect the connectors -1, 2 and 3-.

- Free up the wiring harness.

Note

Note

Ignore item -4-.

- Loosen the clamp -1- and remove the intake air guide from the air filter -2- and free it up.

- Remove the bolt -arrow- and nut -3- and remove the bracket with the air supply unit.

Installing

Install in reverse order of removal and note the following:

- Fill the system. Refer to → Chapter "Air Suspension System, Filling and Bleeding".

Tightening Specifications

- Refer to → Chapter "Overview - Air Supply Unit"

Air Supply Unit, Removing and Installing

Special tools and workshop equipment required

- Torque Wrench 1783 - 2-10Nm -VAG1783-

Removing

Note

Note

Follow the guidelines for clean working conditions. Refer to → Chapter "Guidelines for Clean Working Conditions".

- Disconnect the connector -3- and free up the wire.

- If equipped, remove the connector -2- from the bracket and free it up.

- Remove the air lines -4- from the solenoid valve.

- Loosen the clamp -1- and remove the intake line.

- Remove the bolts -arrows- and remove the air supply unit -5-.

Installing

Install in reverse order of removal.

Tightening Specifications

- Refer to → Chapter "Overview - Air Supply Unit"