Audi Q7: Engine, Securing to Engine and Transmission Holder

Special tools and workshop equipment required

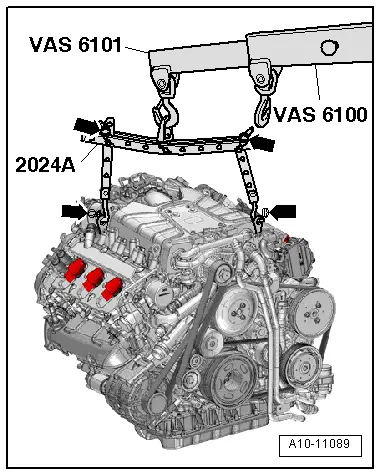

- Engine Sling -2024A-

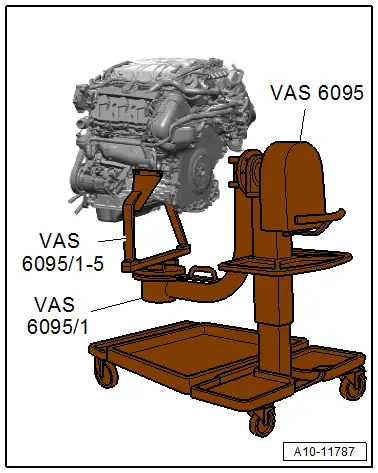

- Engine and Gearbox Bracket -VAS6095A-

- Engine/Transmission Holder - Universal Mounting -VAS6095/1- and Engine/Transmission Holder - V6 FSI Bracket -VAS6095/1-5-

- Shop Crane -VAS6100-

- Lift Arm Extension -VAS6101-

Procedure

- Engine/transmission assembly removed and separated on Scissor Lift Table -VAS6131B-. Refer to → Chapter "Engine and Transmission, Separating".

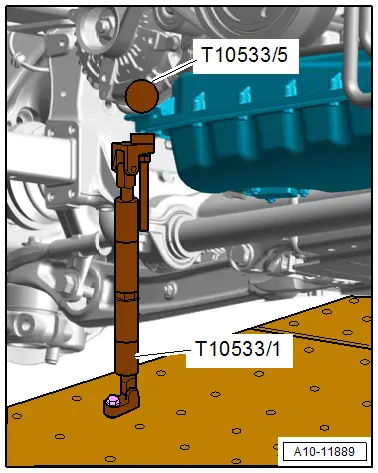

- Engine secured with the Engine Support -T10533-.

WARNING

WARNING

Risk of accident!

The engine may only be transported in the manner described and without the transmission.

- Engage the Engine Sling -2024A- on the engine lifting eyes and on the Shop Crane -VAS6100- with Lift Arm Extension - VAS6101- as shown in the illustration.

Note

Note

To be aligned to the center of gravity of the assembly, the rails with holes of the lifting hooks must be inserted as shown.

WARNING

WARNING

There is the risk of an accident.

Lifting hooks and pins on the engine sling must be secured with securing pins in direction of -arrows-.

- Tension the engine slightly with the shop crane, but do not lift.

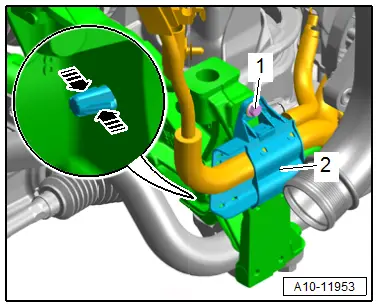

- Remove the bolt -1-.

- Release the catches in direction of -arrows- and free up the bracket -2- for the wires from the subframe.

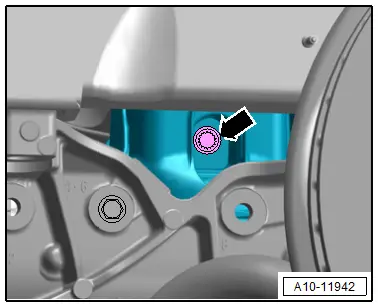

- Remove engine bracket left and right bolt -arrow-.

- Remove the Engine Support -T10533/1- with -T10533/5- from the engine.

- Raise the engine from the engine support.

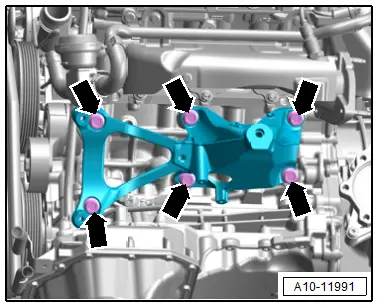

- Remove the bolts -arrows- and the left engine support with the A/C compressor bracket.

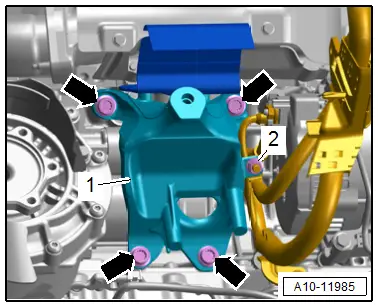

- Remove the nut -2- and free up the ground wire at the engine support -1-.

- Remove the bolts -arrows- and the right engine support.

- Secure the starter on the engine.

- Fasten the engine with the Engine/Transmission Holder - Universal Mounting -VAS6095/1- and Engine/Transmission Holder - V6 FSI Bracket -VAS6095/1-5- on the Engine and Gearbox Bracket -VAS6095A- to 40 Nm as shown.