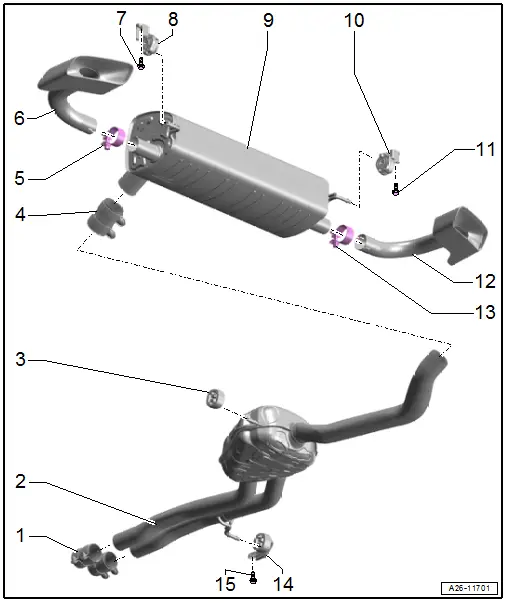

Audi Q7: Exhaust Pipes/Mufflers

Overview - Muffler

1 - Front Clamping Sleeves

- 30 Nm

- Installation position. Refer to → Fig. "Installed Position of Front Clamping Sleeves".

- Pushed all the way onto the front muffler

- Before tightening, align the exhaust system without tension. Refer to → Chapter "Exhaust System, Installing without Tension".

- Tighten threaded connections evenly.

2 - Center Muffler

- Original equipment as one unit with the rear muffler. If a repair is required replace each separately

- Separating point. Refer to → Chapter "Exhaust Pipes/Mufflers, Disconnecting".

- Exhaust System, Installing without Tension. Refer to → Chapter "Exhaust System, Installing without Tension".

3 - Retaining Loop

4 - Rear Clamping Sleeve

- 30 Nm

- For individual replacement of the center and rear mufflers

- Installation position. Refer to → Fig. "Installed Position of Rear Clamping Sleeve".

- Before tightening, align the exhaust system without tension. Refer to → Chapter "Exhaust System, Installing without Tension".

- Tighten threaded connections evenly.

5 - Screw-Type Clamp

- 60 Nm

6 - Left Tail Pipe

7 - Bolt

- 23 Nm

8 - Mount

- Replace if damaged

- Check the pretension. Refer to → Chapter "Exhaust System, Installing without Tension".

9 - Rear Muffler

- Original equipment as one unit with center muffler

- The center muffler and the rear muffler can be replaced individually if a repair is required.

- Separating point between the center and rear muffler. Refer to → Chapter "Exhaust Pipes/Mufflers, Disconnecting".

- Exhaust System, Installing without Tension. Refer to → Chapter "Exhaust System, Installing without Tension".

10 - Mount

- Replace if damaged

- Check the pretension. Refer to → Chapter "Exhaust System, Installing without Tension".

11 - Bolt

- 23 Nm

12 - Right Tail Pipe

13 - Screw-Type Clamp

- 60 Nm

14 - Mount

- Replace if damaged

- Check the pretension. Refer to → Chapter "Exhaust System, Installing without Tension".

15 - Bolt

- Tightening specification. Refer to → Body Exterior; Rep. Gr.66; Underbody Trim Panel; Overview - Tunnel Brace

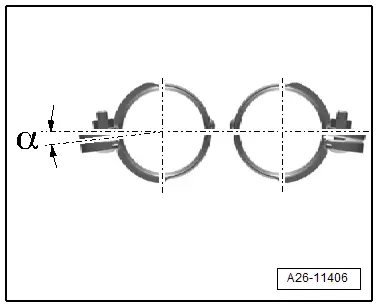

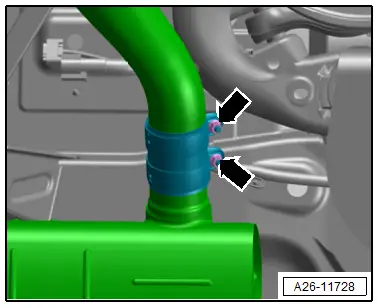

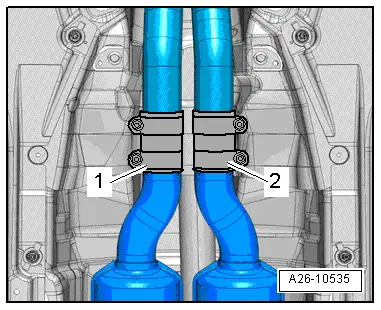

Installed Position of Front Clamping Sleeves

- Position the clamping sleeves in the center on the separating point.

- Installed position: the threaded connections face outward.

- Angle -α- = at least 20º.

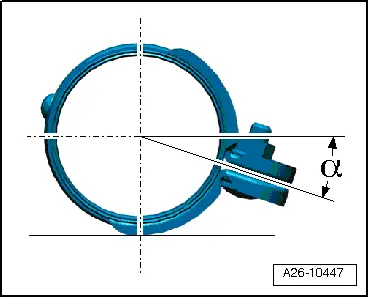

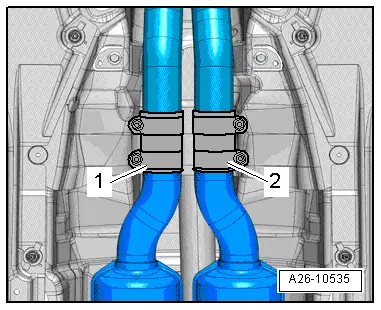

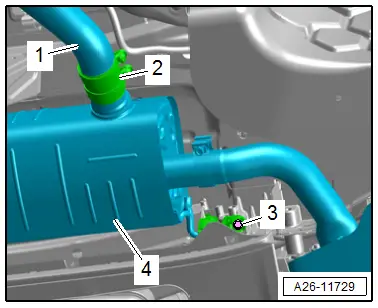

Installed Position of Rear Clamping Sleeve

- Position the clamping sleeve in the center on the separating point.

- Installation position: threaded connections to the right.

- Angle -α- = approximately 20º.

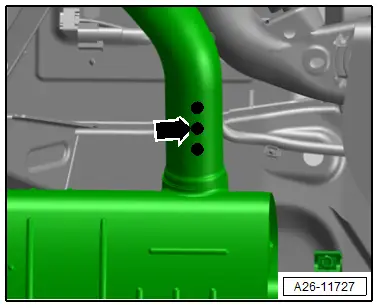

Exhaust Pipes/Mufflers, Disconnecting

- A separating point has been provided in the connecting pipe for individual replacement of the center or rear muffler.

- The separating point is marked by an indentation around the circumference of the exhaust pipe.

Special tools and workshop equipment required

- Chain Pipe Cutter -VAS6254-

Procedure

- Separate the exhaust pipes at a right angle at the separating point -arrow- using a Chain Pipe Cutter -VAS6254-.

- Position the clamping sleeve in the center ti the separation cut (refer to → Fig. "Installed Position of Rear Clamping Sleeve") and tighten the nuts -arrows-.

- Install the exhaust system without tension. Refer to → Chapter "Exhaust System, Installing without Tension".

Tightening Specifications

- Refer to → Chapter "Overview - Muffler"

Front Muffler, Removing and Installing

Removing

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- Seals - Catalytic Converter

- Lock nuts - Front muffler

- Remove the rear noise insulation. Refer to → Body Exterior; Rep. Gr.66; Noise Insulation; Noise Insulation, Removing and Installing.

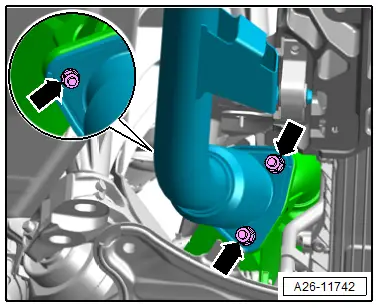

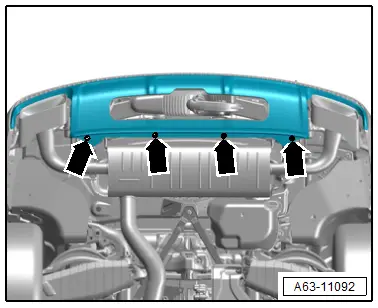

- Remove the nuts -arrows- from the corresponding front muffler.

Caution

Caution

Risk of damaging the decoupling element inside the front exhaust pipe.

Do not bend decoupling element in the front muffler more than 10Âş.

- Remove the bolts -arrows-.

- Loosen the clamping sleeves -1 or 2-, slide it back and remove the corresponding front muffler.

Installing

Install in reverse order of removal and note the following:

Note

Note

Replace seals and self-locking nuts after disassembly.

- Install the exhaust system without tension. Refer to → Chapter "Exhaust System, Installing without Tension".

Tightening Specifications

- Refer to → Chapter "Overview - Muffler"

- Refer to → Body Exterior; Rep. Gr.66; Noise Insulation; Overview - Noise Insulation.

Muffler, Removing and Installing

Muffler with Center Muffler, Removing and Installing, Rear Muffler without Separating Point

Removing

- Remove the center underbody trim panel. Refer to → Body Exterior; Rep. Gr.66; Underbody Trim Panel; Underbody Trim Panels, Removing and Installing.

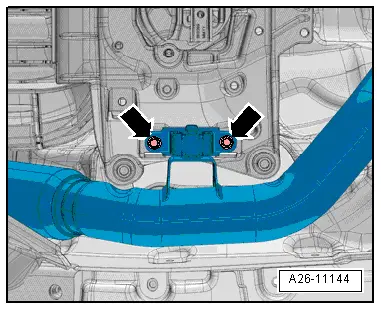

- Remove the bolts -arrows- on the rear diffuser.

- Loosen the front clamping sleeves -1 and 2--arrows- and slide them toward the rear.

- Slightly lower the front exhaust pipe and remove the clamping sleeves.

WARNING

WARNING

Risk of accident due to the weight of the muffler.

A second technician is needed to remove the rear muffler.

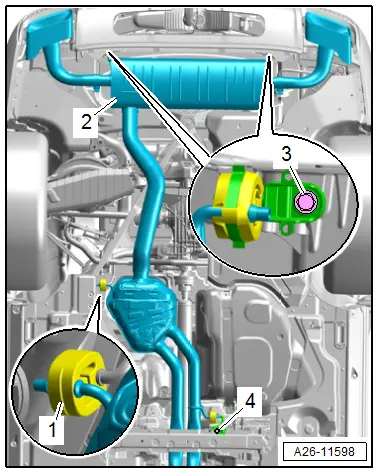

- Remove the left and right bolts -3- and disengage the retaining loop -1-.

- Remove the bolt -4- and the muffler -2-. While doing so, pay attention to the diffuser.

Installing

Install in reverse order of removal and note the following:

- Install the exhaust system without tension. Refer to → Chapter "Exhaust System, Installing without Tension".

Tightening Specifications

- Refer to → Chapter "Overview - Muffler"

- Refer to → Body Exterior; Rep. Gr.66; Underbody Trim Panel; Overview - Underbody Trim Panels.

- Refer to → Body Exterior; Rep. Gr.63; Rear Bumper; Overview - Bumper Cover.

Muffler, Removing and Installing, Rear Muffler with Separating Point

Removing

- Loosen the clamping sleeve -2- and push it on the exhaust pipe.

- Remove the left and right bolts -3- and remove the muffler -4-.

- Tie up the exhaust pipe -1-.

Installing

Install in reverse order of removal and note the following:

- Install the exhaust system without tension. Refer to → Chapter "Exhaust System, Installing without Tension".

Tightening Specifications

- Refer to → Chapter "Overview - Muffler"

Exhaust System, Installing without Tension

Procedure

- Align the exhaust system when cold.

Exhaust System, Aligning

- Loosen the threaded connections on the front clamping sleeves.

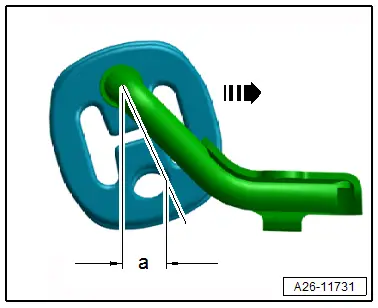

- Push the exhaust system far enough forward in direction of -arrow- until the pre-load on the retaining loop at the exhaust pipe is -a- = 6 to 10 mm.

- Position the front clamping sleeves (refer to → Fig. "Installed Position of Front Clamping Sleeves") and tighten the threaded connections evenly.

Tail Pipes, Aligning

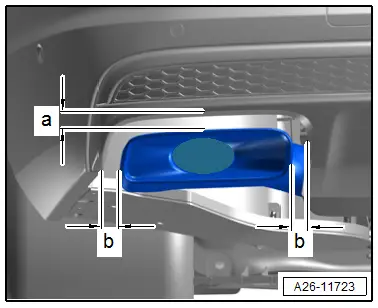

- Check distance of left and right tail pipes to bumper:

- Dimension -a- 16 mm.

- Dimension -b- left = dimension -b- right.

Tightening Specifications

- Refer to → Chapter "Overview - Muffler"

Exhaust System, Checking for Leaks

- Start the engine and let it run at idle.

- Seal the tail pipes with cloths or plugs during the leakage test.

- Check for leaks by listening at connection areas at cylinder head and exhaust manifold, exhaust manifold and front exhaust pipe, etc.

- Repair the determined leaks.