Audi Q7: Hydraulic System

Brake Fluid General Information

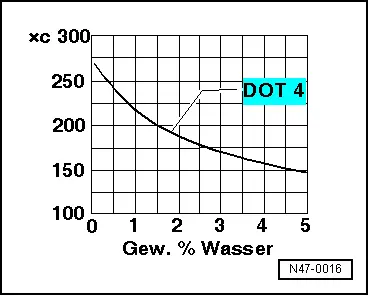

Brake Fluid Is Hygroscopic, Meaning That It Has the Ability to Absorb Water and Moisture from the Air.

If water has been absorbed, the boiling point will drop, for example, during high braking temperatures the brake fluid may develop steam bubbles and cause the brakes to fail.

Over time, brake fluid will darken in color. Dark-colored brake fluid does not specify anything about its quality. The color forms due to chemical reactions.

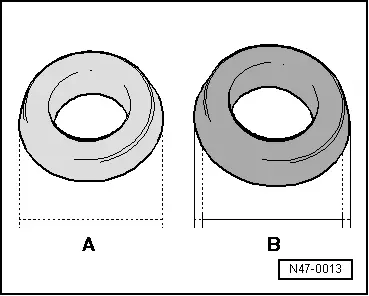

Even the smallest amount on a seal or boot can cause the part to change and thereby affect the function of the brake system. The results of an unclean brake system first show themselves months later, causing increased repair costs, especially on vehicles with ABS.

A - Boot - Original Size

B - Boot - swollen through contact with mineral oil

As a Result of the Previously Mentioned Points:

- Keep containers of brake fluid closed securely. This is to make sure that no oil, dirt or cleaning materials and no humidity can enter the container.

- Store containers of brake fluid away from oil (even hydraulic oil) and cleaning fluids to prevent an accidental mixing of both fluids or even filling the brake system with the wrong fluid.

WARNING

WARNING

Health Risk.

- Brake fluid is poisonous. NEVER siphon brake fluid by mouth!

- To prevent skin contact with brake fluid, wear chemical resistant safety gloves.

- Follow all disposal regulations.

Risk of accident due to steam bubbles developing when the water content in the brake fluid is too high.

- Brake fluid is hygroscopic, meaning that it absorbs moisture from the surrounding air.

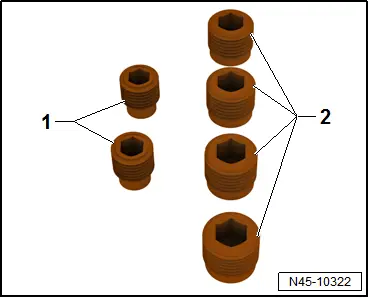

- Seal the open brake hoses and brake line with plugs from the Assembly Part Set -5Q0 698 311-.

- Always store brake fluid in air-tight containers.

Malfunctions from contact with brake fluid with fluids containing mineral oils.

Brake fluid must never come into contact with fluids containing mineral oils (oil, gas, cleaning solutions). Safety gloves must be free of oil and grease.

Risk of damaging the painted surfaces.

Due to its caustic nature, brake fluid must also never be brought into contact with paint. Wash off any spilled brake fluid immediately with plenty of water.

Note

Note

Only use new brake fluid.

Hydraulic System, Bleeding

Hydraulic System, Bleeding with Brake Charger/Bleeding Unit

Special tools and workshop equipment required

- Brake Charger/Bleeder Unit -VAS5234- with Brake Bleeder Adapter Adapter -VAS5234/1-

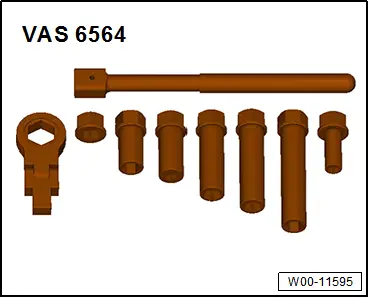

- Brake Bleeding Tool Set -VAS6564-

Note

Note

- On this vehicle the brake system is divided by axle.

- Right and left front axle

- Right and left rear axle

Note

Note

- The bleeding of hydraulic system using the Brake Charger/Bleeder Unit -VAS5234- is described.

- An initial pressure of 2 bar (29 psi) is required to bleed the ABS Hydraulic Unit -N55-.

Procedure

- Wheels removed. Refer to → Suspension, Wheels, Steering; Rep. Gr.44; Wheels and Tires.

Note

Note

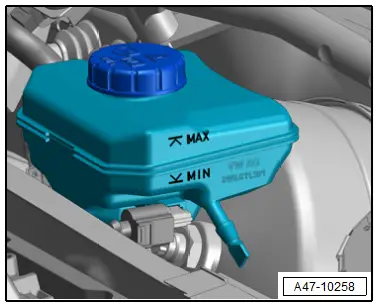

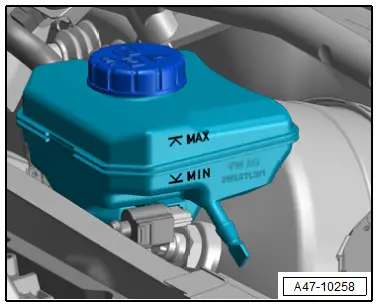

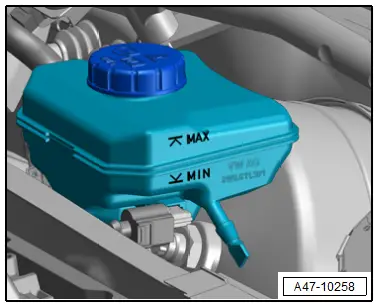

Make sure that the brake fluid reservoir is always filled, but not over the "MAX" mark.

- Fill the brake fluid reservoir up to the "MAX" mark.

- Connect the Brake Charger/Bleeder Unit -VAS5234-.

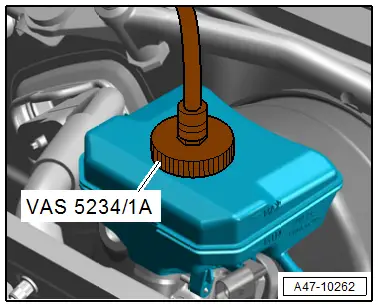

- Attach the Brake Bleeder Adapter -VAS5234/1A- on the brake fluid reservoir.

- Adjust the pressure direction on the Brake Charger/Bleeder Unit -VAS5234-. Refer to the Brake Charger/Bleeder Unit -VAS5234- Owner's Manual.

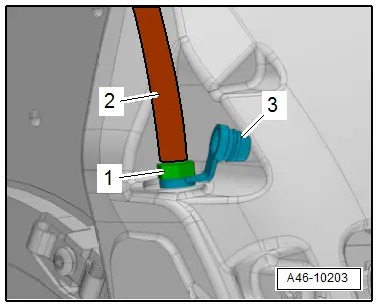

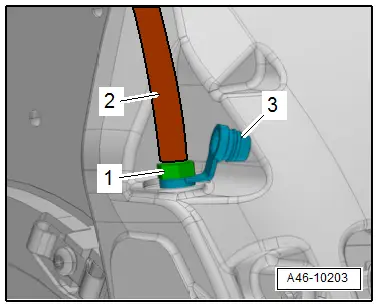

- Remove the protective cap -3- from the bleed screw -1- on the respective brake caliper.

- Connect the bleeder bottle hose -2- as shown.

Note

Note

- Use a suitable bleeder hose. It must seat tightly on the bleed screw so that no air can enter the brake system.

- The front brake calipers each have two bleed screws.

Bleeding sequence

1 - Inner Left Front Brake Caliper

2 - Outer Left Front Brake Caliper

3 - Inner Right Front Brake Caliper

4 - Outer Right Front Brake Caliper

5 - Left Rear Brake Caliper

6 - Right Rear Brake Caliper

- Leave the bleed screw open, with brake fluid hose connected, until brake fluid flows out clear and free of air bubbles.

- Press brake pedal five times to assist the bleeding procedure.

- Tighten the bleed screw, remove the bleed hose and place the dust cap on the bleed screw.

- Repeat the bleeding procedure in the specified sequence for the remaining brake calipers.

- Fill the brake fluid reservoir under consideration of brake pad wear up to the "MAX" mark and screw on the fuel cap.

Note

Note

Do not add more brake fluid above the "MAX" mark otherwise it will leak out of the reservoir.

- Start the engine and check the brake pedal travel and pressure.

- If the pedal travel is too long, check the brake system for leaks or repeat the bleeding procedure.

Note

Note

A road test must be performed after bleeding. During this, at least one ABS regulation must be performed at all four wheels!

WARNING

WARNING

Risk of accident!

Make sure the brakes are working correctly before driving the vehicle for the first time.

Tightening Specifications

- Refer to → Chapter "Overview - Front Brakes"

- Refer to → Chapter "Overview - Rear Brakes"

Hydraulic System, Bleeding without Brake Charger/Bleeding Unit

Special tools and workshop equipment required

- Container

- Brake Bleeding Tool Set -VAS6564-

Note

Note

- On this vehicle the brake system is divided by axle.

- Right and left front axle

- Right and left rear axle

Procedure

- Wheels removed. Refer to → Suspension, Wheels, Steering; Rep. Gr.44; Wheels and Tires.

Note

Note

Make sure that the brake fluid reservoir is always filled.

- Fill the brake fluid reservoir up to the "MAX" mark.

- Remove the protective cap -3- from the bleed screw -1- on the respective brake caliper.

- Connect the bleeder bottle hose -2- as shown.

Note

Note

- Use a suitable bleeder hose. It must seat tightly on the bleed screw so that no air can enter the brake system.

- The front brake calipers each have two bleed screws.

- Bleed the brake caliper at each bleed screw.

Bleeding Sequence

1 - Inner Left Front Brake Caliper

2 - Outer Left Front Brake Caliper

3 - Inner Right Front Brake Caliper

4 - Outer Right Front Brake Caliper

5 - Left Rear Brake Caliper

6 - Right Rear Brake Caliper

- Build pressure up in brake system by pumping brake pedal.

Note

Note

Slowly press the brake pedal to prevent bubbles.

- As soon as pressure is built up, hold brake pedal in depressed position.

- Open the bleeder screw, with bleeder bottle hose connected, until the pressure is relieved (pedal drops).

- Hold the pedal in the completely depressed position and close the bleed screw.

- Release brake pedal and wait approximately 2 seconds so that brake fluid can flow out of the brake fluid reservoir.

- Repeat the procedure until the brake fluid flows out clear and free of bubbles.

- Tighten the bleed screw, remove the bleed hose and place the dust cap on the bleed screw.

- Repeat the bleeding procedure in the specified sequence for the remaining brake calipers.

- Fill the brake fluid reservoir under consideration of brake pad wear up to the "MAX" mark and screw on the fuel cap.

Note

Note

Do not add more brake fluid above the "MAX" mark otherwise it will leak out of the reservoir.

- Start the engine and check the brake pedal travel and pressure.

- If the pedal travel is too long, check the brake system for leaks or repeat the bleeding procedure.

WARNING

WARNING

Risk of accident!

Make sure the brakes are working correctly before driving the vehicle for the first time.

Tightening Specifications

- Refer to → Chapter "Overview - Front Brakes"

- Refer to → Chapter "Overview - Rear Brakes"

Leak Test

Special tools and workshop equipment required

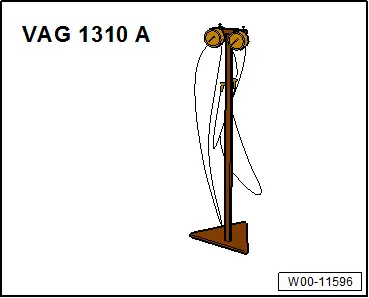

- Brake Pressure Gauge -VAG1310A-

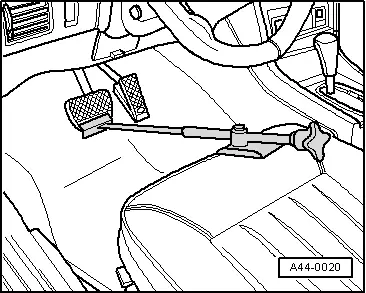

- Brake Pedal Actuator -VAG1869/2-.

High Pressure Testing:

- Brake system (brake master cylinder, brake hoses, brake lines and brake calipers) tested for function and leaks.

- Remove bleed screw at one of the front brake calipers. Connect the Brake Pressure Gauge -VAG1310A- and bleed.

- Insert the Brake Pedal Actuator -VAG1869/2- between the brake pedal and driver seat. Apply pressure to the brake pedal until the pressure gauge indicates a pressure of 50 bar (725.18 psi). The pressure must not drop more than 4 bar (58.01 psi) during the test period of 45 seconds.

- Replace the brake master cylinder if the pressure decrease is too high.

Low Pressure Testing:

- Set the brake pedal actuator back far enough that the pressure gauge indicates 6 bar (87.02 psi) positive pressure.

- The pressure must not drop by more than 1 bar (14.5 psi) during a test period of 3 minutes.

- Replace the brake master cylinder if the pressure decrease is too high.

Special Tools

Special tools and workshop equipment required

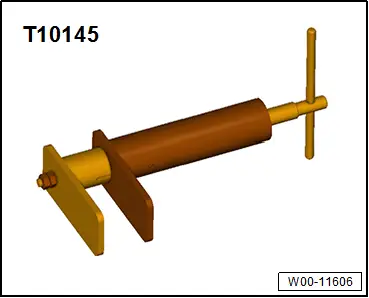

- Piston Resetting Tool -T10145-

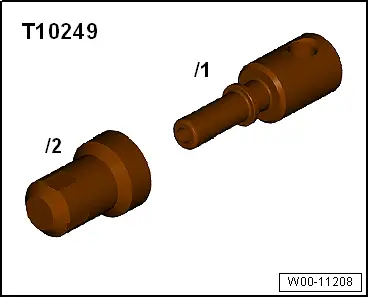

- Sealing Tool -T10249-

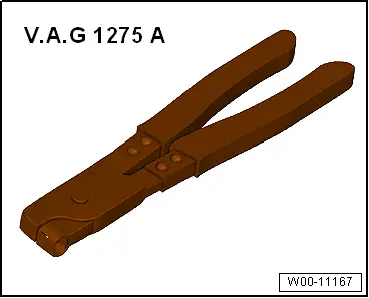

- Hose Clip Pliers -VAG1275A-

- Brake Pressure Gauge -VAG1310A-

- Torque Wrench 1331 5-50Nm -VAG1331-

- Brake Charger/Bleeder Unit -VAS5234- with Brake Bleeder Adapter Adapter -VAS5234/1-

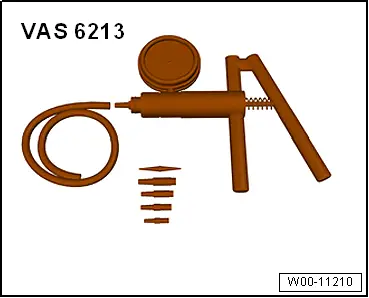

- Hand Vacuum Pump -VAS6213-

- Brake Bleeding Tool Set -VAS6564-

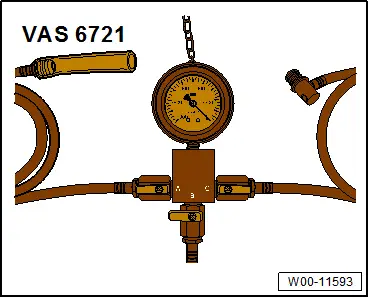

- Brake Servo Tester -VAS6721-

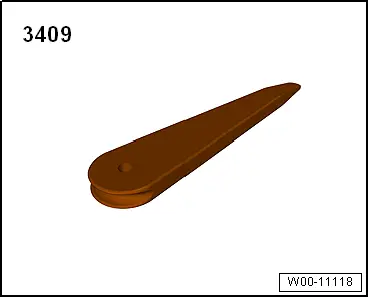

- Trim Removal Wedge -3409-

- M10 plug -item 1- or M12 -item 2- from the Assembly Part Set -5Q0 698 311-

Revision History

DRUCK NUMBER: A005A011221