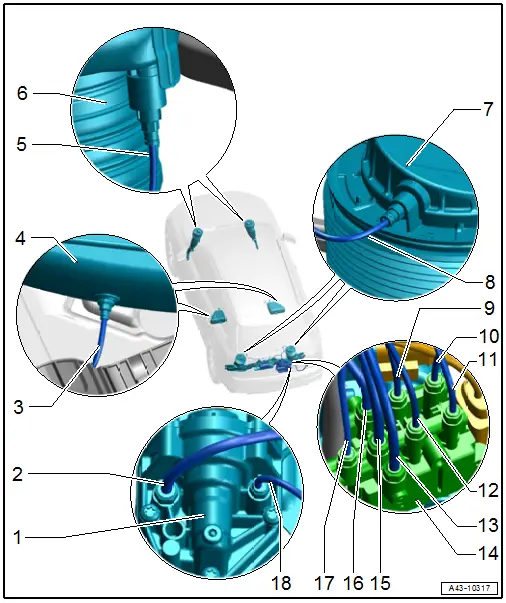

Audi Q7: Overview - Air Lines

1 - Air Supply Unit with Level Control System Compressor Motor -V66-

- Overview. Refer to → Chapter "Overview - Air Supply Unit".

2 - Air Line "Brown"

- To solenoid valve block

- Connector tightening specification 3 Nm

3 - "Purple" Air Line

- Connecting piece tightening specification 5 Nm

- From the solenoid valve

4 - Pressure Reservoir

- Removing and installing. Refer to → Chapter "Pressure Reservoir, Removing and Installing".

5 - Air Line

- Connector tightening specification 2 Nm

- Left "red", right "green"

- From the solenoid valve

- Front air line routing. Refer to → Fig. "Air Line Routing to the Front Air Spring"

- Do not loosen the residual pressure valve

6 - Front Air Spring

7 - Rear Air Spring

8 - Air Line

- Connector tightening specification 2 Nm

- Left "black", right "blue"

- From the solenoid valve

- If there is a damage claim replace completely. The repair of a damaged air line is not permitted.

- Rear air line routing. Refer to → Fig. "Air Line Routing on the Subframe to the Rear Air Spring"

9 - "Green" Air Line

- Connector tightening specification 2 Nm

- To the right front air spring

10 - "Blue" Air Line

- Connector tightening specification 2 Nm

- To the right rear air spring

11 - "Black" Air Line

- Connector tightening specification 2 Nm

- To the left rear air spring

12 - "Red" Air Line

- Connector tightening specification 2 Nm

- To the left front air spring

13 - "Purple" Air Line

- Connector tightening specification 3.6 Nm

- To the right pressure reservoir

14 - Solenoid Valve Block

15 - "Purple" Air Line

- To the left pressure reservoir

- Connector tightening specification 3.5 Nm

16 - Air Line "Brown"

- From the air supply unit

- Connector tightening specification 3.5 Nm

17 - Air Line "Brown"

- To the air supply unit

- Connector tightening specification 2 Nm

18 - Air Line "Brown"

- From the solenoid valve

- Connector tightening specification 2 Nm

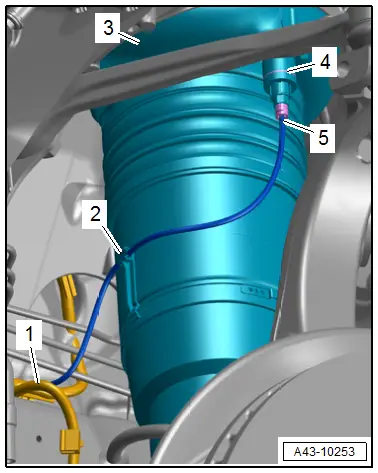

Air Line Routing to the Front Air Spring

- Contains the air line -5- on the Clip -2- in the wiring harness -1-.

3 - Front Air Spring

4 - Residual Pressure Retaining Valve - Do Not Loosen

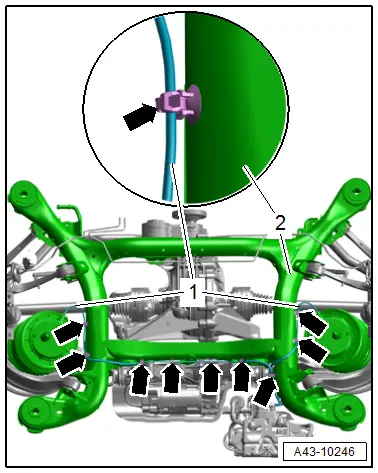

Air Line Routing on the Subframe to the Rear Air Spring

- Secure the air line -1- with the clips -arrows- on the subframe -2- as shown.

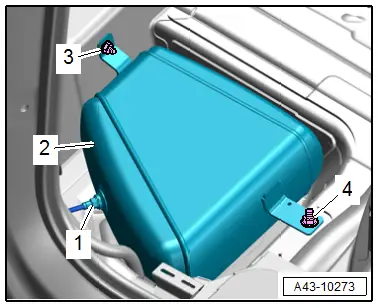

Pressure Reservoir - Tightening Specification

- Tighten the bolt -3- and nut -4- to 6 Nm.

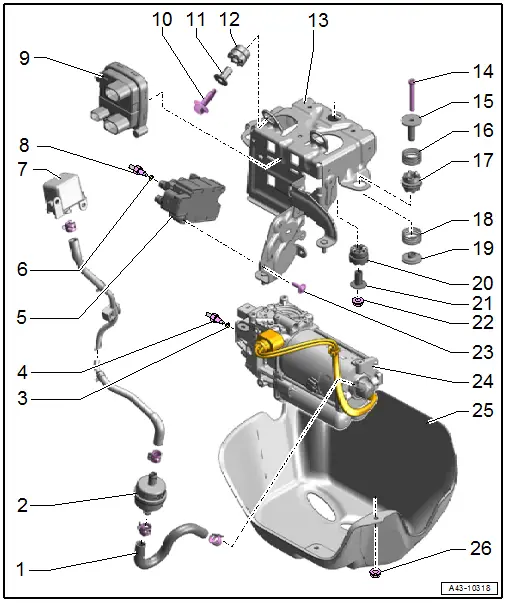

Overview - Air Supply Unit

1 - Hose

2 - Filter

- Removing and installing. Refer to → Chapter "Filter, Removing and Installing".

3 - O-Ring

- Replace after removing

4 - Air Line

- Air lines overview. Refer to → Chapter "Component Location Overview - Air Suspension"

- Connecting piece tightening specification. Refer to → Chapter "Overview - Air Lines".

5 - Solenoid Valve Block

- Line arrangement. Refer to → Chapter "Overview - Air Lines".

- Removing and installing. Refer to → Chapter "Solenoid Valve Block, Removing and Installing".

6 - O-Ring

- Replace after removing

7 - Muffler

- Component location in the interior (spare tire well)

8 - Air Line

- Air lines overview. Refer to → Chapter "Component Location Overview - Air Suspension"

- Connecting piece tightening specification. Refer to → Chapter "Overview - Air Lines".

9 - Compression Control Module

- Removing and Installing. Refer to → Chapter "Level Control System Compressor Electronics -J1135-, Removing and Installing".

10 - Bolt

- 9 Nm

- Quantity: 2

11 - Spacer Sleeve

12 - Grommet

13 - Bracket

- For the air supply unit

14 - Bolt

- 5 Nm

15 - Spacer Sleeve

16 - Spring

17 - Grommet

18 - Spring

19 - Spring Support

20 - Grommet

21 - Spacer Sleeve

22 - Nut

- 9 Nm

23 - Bolt

- 3.5 Nm

24 - Air Supply Unit with Level Control System Compressor Motor -V66-

- Removing and installing. Refer to → Chapter "Air Supply Unit, Removing and Installing".

25 - Cover

26 - Nut

- 9 Nm