Audi Q7: Overview - Steering Gear

Audi Q7 (4M) 2016-2025 Workshop Manual / Chassis / Suspension, Wheels, Steering / Steering / Overview - Steering Gear

Overview - Steering Gear

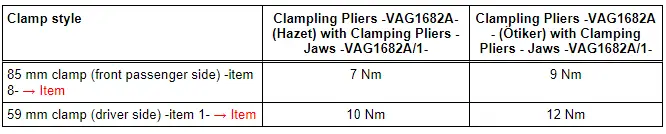

1 - Steering Gear with Tie Rods

- With integrated Power Steering Control Module -J500-

- The Power Steering Control Module -J500- cannot be replaced separately if faulty replace the steering gear.

- Removing and installing. Refer to → Chapter "Steering Gear, Removing and Installing".

- Servicing. Refer to → Chapter "Overview - Steering Gear, Tie Rods".

2 - Bolt

- 80 Nm +180º

- Replace after removing

3 - Subframe

4 - Nut

- Pushed into the subframe

- Replace after removing

5 - Steering Intermediate Shaft

- Removing and installing. Refer to → Chapter "Steering Intermediate Shaft, Removing and Installing".

6 - Bolt

- Tightening specification. Refer to -item 1-

7 - Wheel Bearing Housing

- Removing and installing. Refer to → Chapter "Wheel Bearing Housing, Removing and Installing".

8 - Nut

- 140 Nm

- Replace after removing

- After loosening remove the adhesive residue from the pin threads

Overview - Steering Gear, Tie Rods

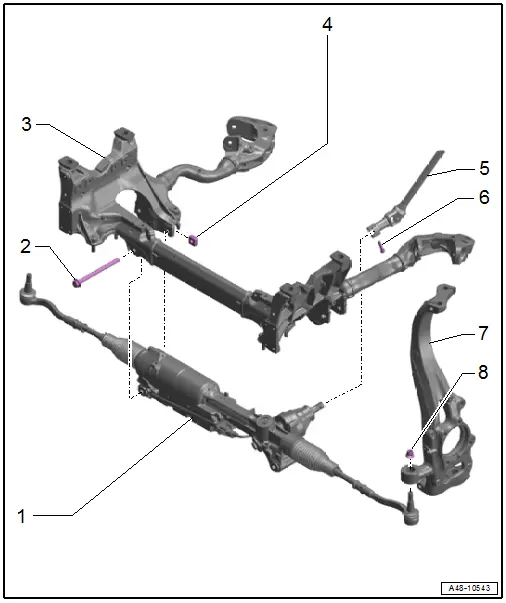

1 - Clamp

- Replace after removing

- Do not open the new clamp

- Tensioning.

2 - Tie Rod

- 100 Nm

- Grease the joint with Steering Gear Grease -G 052 168 A1-

- Removing and installing. Refer to → Chapter "Tie Rod, Removing and Installing".

3 - Steering Gear

- Grease the steering rack with Steering Gear Grease -G 052 168 A1-

- Removing and installing. Refer to → Chapter "Steering Gear, Removing and Installing".

4 - Tie Rod End

- Check dust cap for damage and correct seating.

- Check dimension. Refer to → Fig. "Tie Rod End Check Dimension"

- Removing and installing. Refer to → Chapter "Tie Rod End, Removing and Installing".

5 - Nut

- 80 Nm

- When loosening and tightening, counterhold at the tie rod end

6 - Spring Clamp

- Replace after removing

- Spring Clamp, Installing.

7 - Boot

- Check for damage

- Replace after removing

- Must not be twisted when toe is being adjusted

- Do not crumple the boot

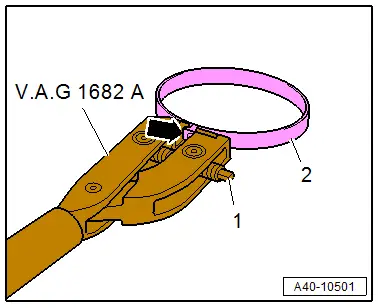

- Make sure it is installed correctly. Refer to → Fig. "Tension the Inner Clamp Using the Clampling Pliers -VAG1682A-.".

- Replacing. Refer to → Chapter "Boot, Removing and Installing".

8 - Clamp

- Replace after removing

- Do not open the new clamp

- Tensioning. Refer to → Fig. "Tension the Inner Clamp Using the Clampling Pliers -VAG1682A-.".

9 - Tie Rod

- 100 Nm

- Grease the joint with Steering Gear Grease -G 052 168 A1-

- Removing and installing. Refer to → Chapter "Tie Rod, Removing and Installing".

10 - Tie Rod End

- Check dust cap for damage and correct seating.

- Check dimension. Refer to → Fig. "Tie Rod End Check Dimension"

- Removing and installing. Refer to → Chapter "Tie Rod End, Removing and Installing".

11 - Nut

- 80 Nm

- When loosening and tightening, counterhold at the tie rod end

12 - Spring Clamp

- Replace after removing

- Spring Clamp, Installing. Refer to → Fig. "Outer Boot Installation Position".

13 - Boot

- Check for damage

- Replace after removing

- Do not turn when toe is being adjusted

- Do not crumple the boot

- Do not bring into contact with hard or sharp objects.

- Installation position. Refer to → Fig. "Outer Boot Installation Position".

- Removing and installing. Refer to → Chapter "Boot, Removing and Installing".

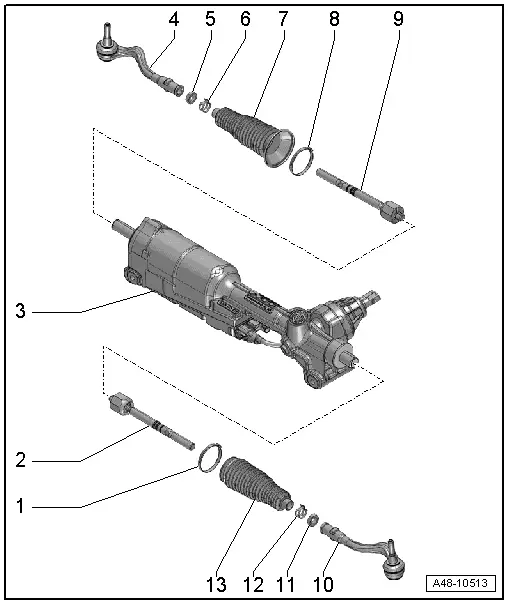

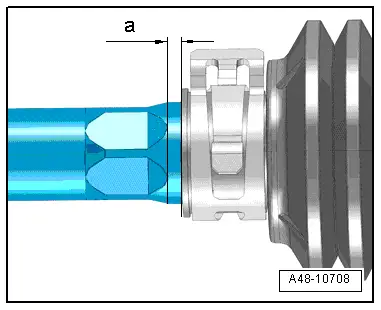

Tie Rod End Check Dimension

- Place a steel ruler -2- on the tie rod end and push it all the up to the edge -arrow- of the tie rod end -1-.

- Replace the complete steering gear with the tie rod and tie rod end if the check dimension -a- is less than 200 mm.

Outer Boot Installation Position

- Dimension -a- = 2 mm.

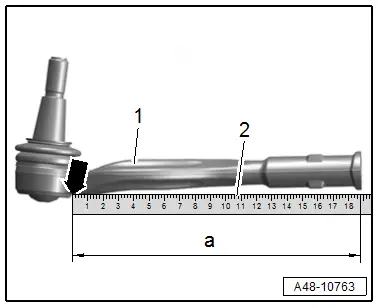

Tension the Inner Clamp Using the Clampling Pliers -VAG1682A-.

- Attach the Clampling Pliers -VAG1682A- as shown.

- The jaws on the pliers must be centered -arrow- on the clamp -2-.

Note

Note

- The spindle threads must turn easily. If necessary, coat with MoS2 lubricating grease.

- If difficult to tighten, for example because of dirty threads, the proper clamping force of the clamping sleeve will not be reached even when tightened to the specification.

- Tension the clamp by turning the spindle -1- with the torque wrench, at the same time do not tilt the clamping pliers.

Tightening Specifications