Audi Q7: Sensors

Intake Air Temperature Sensor -G42-/Manifold Absolute Pressure Sensor -G71-, Removing and Installing

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- O-ring - IAT/MAP sensor

Removing

- Remove the engine cover. Refer to → Chapter "Engine Cover, Removing and Installing".

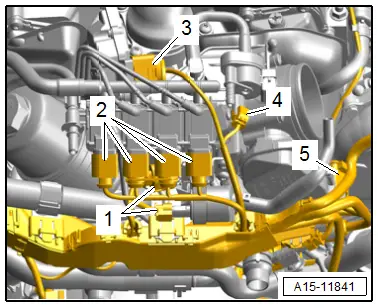

- Disconnect the connectors -1 through 4-.

Note

Note

Ignore -5-.

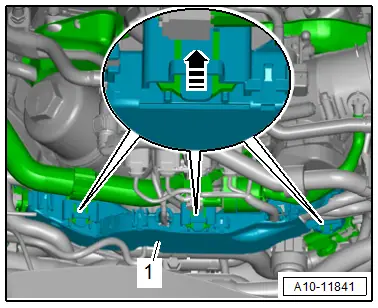

- Release the retainers in direction of -arrow- and remove wiring duct -1- toward the rear.

- Push the wiring duct downward.

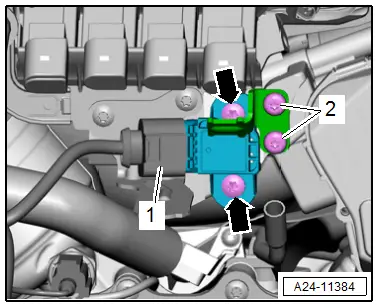

- Remove the Crankcase Ventilation Shut-Off Valve -N548- from the bracket and move it to the side.

- Remove the bolts -2-, and remove the bracket for the Crankcase Ventilation Shut-Off Valve -N548-.

- Remove the bolts -arrows- and remove the Intake Air Temperature Sensor -G42-/Manifold Absolute Pressure Sensor - G71-.

Installing

Install in reverse order of removal and note the following:

Note

Note

Replace the O-rings after removing them.

- Connections and wire routing. Refer to → Wiring diagrams, Troubleshooting & Component locations.

- Install the engine cover. Refer to → Chapter "Engine Cover, Removing and Installing".

Tightening Specifications

- Refer to → Chapter "Overview - Supercharger"

Fuel Pressure Sensor -G247-, Removing and Installing

Special tools and workshop equipment required

- Elbow Assembly Tool -T10118-

- Socket - 27mm -T40218- or 27 mm socket, commercially available

Removing

- Remove the supercharger. Refer to → Chapter "Supercharger, Removing and Installing".

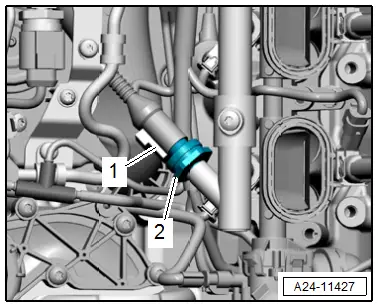

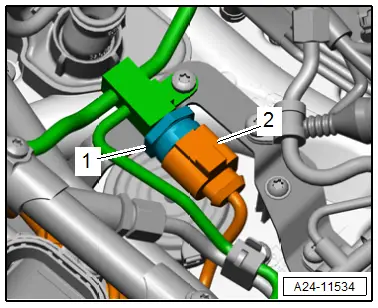

- Disconnect the connector -1-.

WARNING

WARNING

The fuel system is under pressure.

Risk of injury from fuel spraying out.

- Wear protective eyewear.

- Wear safety gloves.

- Reduce the pressure: place clean cloths around the connection point and carefully open the connection point.

- Remove the Fuel Pressure Sensor -G247--2-.

Installing

Install in reverse order of removal and note the following:

- Before tightening the fuel pressure sensor check the connection tightening specification.

- Install the supercharger. Refer to → Chapter "Supercharger, Removing and Installing".

Tightening Specifications

- Refer to → Chapter "Overview - Fuel Rail with Fuel Injectors"

Low Fuel Pressure Sensor -G410-, Removing and Installing

Removing

- Remove the supercharger. Refer to → Chapter "Supercharger, Removing and Installing".

- Disconnect the connector -2-.

WARNING

WARNING

The fuel system is under pressure.

Risk of injury from fuel spraying out.

- Wear protective eyewear.

- Wear safety gloves.

- Reduce the pressure: place clean cloths around the connection point and carefully open the connection point.

- Remove the Low Fuel Pressure Sensor -G410--1-.

Installing

Install in reverse order of removal and note the following:

- Install the supercharger. Refer to → Chapter "Supercharger, Removing and Installing".

Tightening Specifications

- Refer to → Chapter "Overview - Intake Manifold Lower Section with Fuel Rail"