Audi Q7: Solenoid Coupling, Removing and Installing

Special tools and workshop equipment required

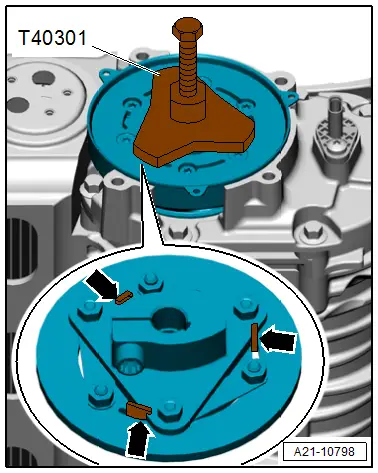

- Clutch Module Puller -T40301-

- Clutch Module Centering Device -T40302-

- Test Adapter For Compressor Module -VAS6909A-

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- O-ring - Solenoid coupling

Removing

- Supercharger secured to engine/transmission holder for repair work. Refer to → Chapter "Supercharger, Securing to Engine/Transmission Holder for Repair Work".

- Remove the coolant pipes from the supercharger. Refer to → Chapter "Supercharger Coolant Pipes, Removing and Installing".

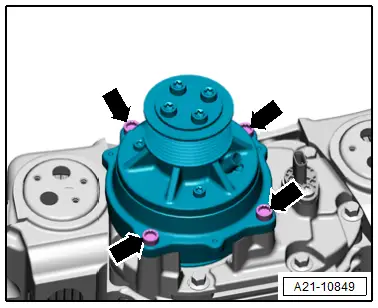

- Remove the bolts -arrows-.

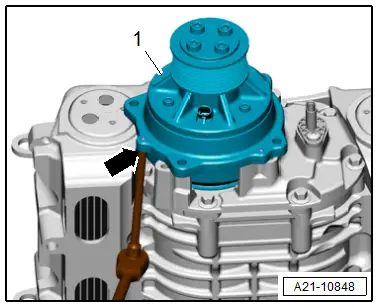

- Slightly lift the solenoid coupling -1- and turn until one of the three trim bolts is accessible.

- Remove the first bolt -arrow-.

- Remove the remaining bolts, to do so turn the solenoid coupling respectively 1/3 turn further.

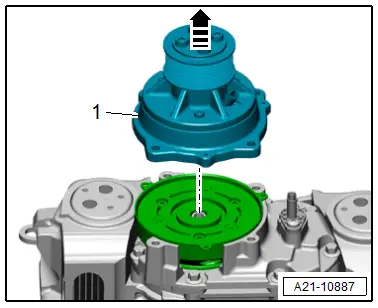

- Remove the solenoid coupling -1- in direction of -arrow-.

- Loosen the clamping screw -arrow- for the drive plate two turns by turning the drive plate in the respective position.

- Install the Clutch Module Puller -T40301- on the drive plate.

- The puller claws -arrows- must engage with the drive plate as shown.

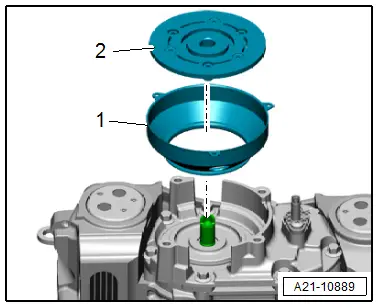

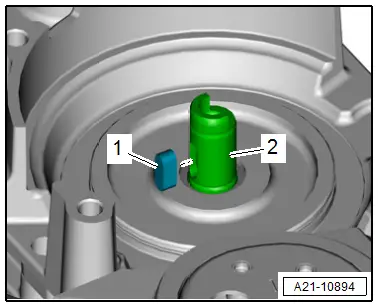

- Remove the drive plate -2-.

- Remove trim -1-.

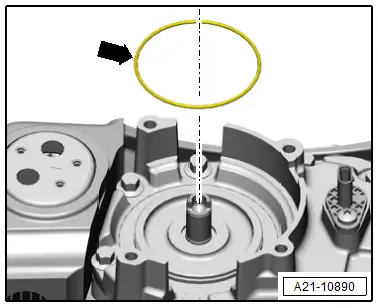

- Remove the O-ring -arrow-.

Check the Sacrificial Liner and the Outer Friction Lining for Wear.

Note

Note

Before reinstalling a used solenoid coupling the sacrificial liner and the outer friction lining must be checked for wear. If new solenoid coupling is installed this step does not apply.

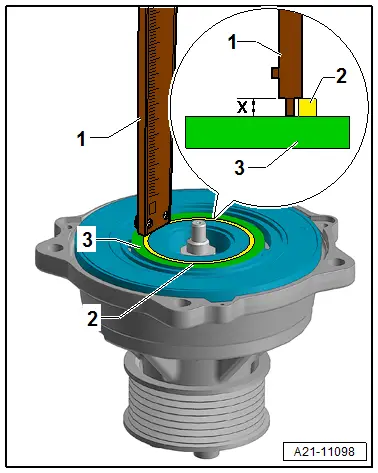

- Place the caliper -1- as shown on the highest point on the sacrificial liner -2- and measure the distance -X- to the friction lining -3-.

- Specified value -X-: minimum 0.2 mm.

- Perform the measurement all around on at least three locations.

- If specified value is not reached, replace the solenoid coupling.

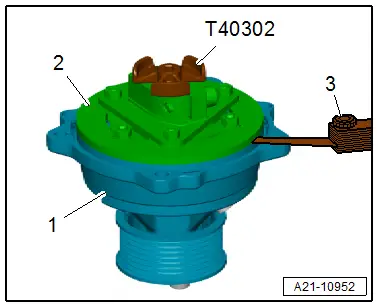

- Place the drive plate -2- on the solenoid coupling -1- and install the Clutch Module Centering Device -T40302- hand-tight.

- With the feeler gauge -3- check the distance of the outer friction lining to the outer friction surface.

- Specified value: minimum 0.2 mm.

- Perform the measurement all around on at least three locations.

- If specified value is not reached, replace the solenoid coupling.

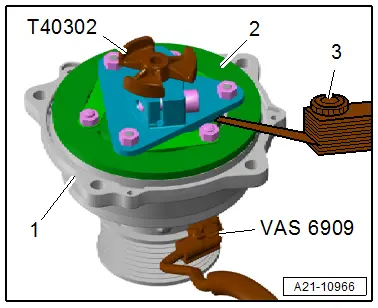

- The driver is still placed -2- on the solenoid coupling -1- and the Clutch Module Centering Device -T40302- is installed hand-tight.

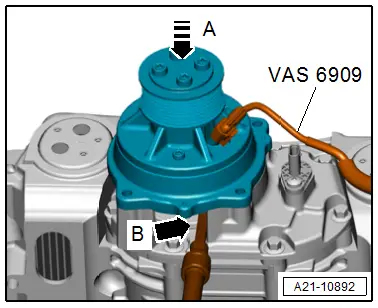

- Connect the Test Adapter For Compressor Module -VAS6909- to a 12V battery or on the vehicle jump start terminal.

- Connect the Test Adapter for Compressor Module -VAS6909- connector with the solenoid coupling and switch on the power supply to the solenoid coupling.

Caution

Caution

There is a risk of destroying the solenoid coupling.

- The solenoid coupling must not be connected longer than 15 minutes to the power supply.

- The current feed heats the solenoid coupling.

- With the feeler gauge -3- on the position shown in the illustration check the distance from the clamping hub -shown in blue- to the outer friction surface in the energized state.

- Perform this measurement on all three locations on the clamping hub.

- Specified value: maximum 1.3 mm

- If specified value is exceeded, replace the solenoid coupling.

- Switch off the Test Adapter For Compressor Module -VAS6909A-.

Installing

Note

Note

Replace the O-ring after removing.

- Lay the O-ring -arrow- in the groove on the compressor housing.

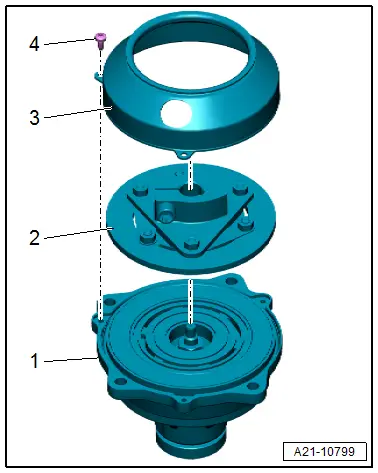

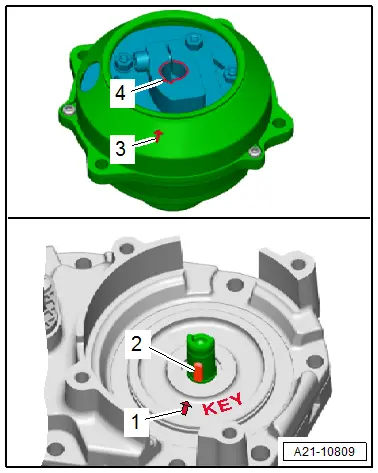

- Place the driver -2- on the solenoid coupling -1-.

- Place the trim -3- on the solenoid coupling and secure with three bolts -4-.

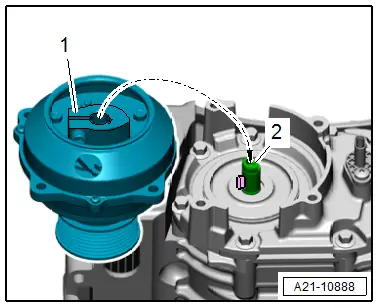

- Insert the Clutch Module Centering Device -T40302- in the drive plate and the solenoid coupling.

- The drive plate is centered to the solenoid coupling.

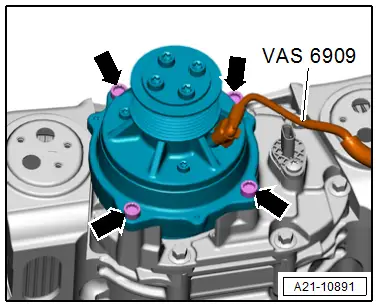

- Connect the Test Adapter For Compressor Module -VAS6909- to a 12V battery or on the vehicle jump start terminal.

- Connect the Test Adapter for Compressor Module -VAS6909- connector with the solenoid coupling and switch on the power supply to the solenoid coupling.

- With the power supply switched on the drive plate is secured on the solenoid coupling.

Note

Note

- Pay attention during the assembly that the solenoid coupling current feed with the Test Adapter for Compressor Module -VAS6909- is not interrupted.

- Interrupting the solenoid coupling current feed with the Test Adapter for Compressor Module -VAS6909- may only take place when the clamping hub clamping screw is secured on the shaft.

Caution

Caution

There is a risk of destroying the solenoid coupling.

- The solenoid coupling must not be connected longer than 15 minutes to the power supply.

- The current feed heats the solenoid coupling.

- Remove the Clutch Module Centering Device -T40302- with the power supply switched on.

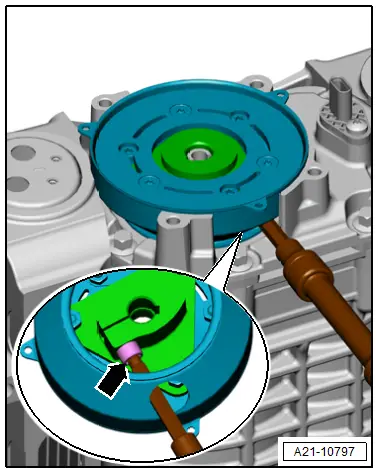

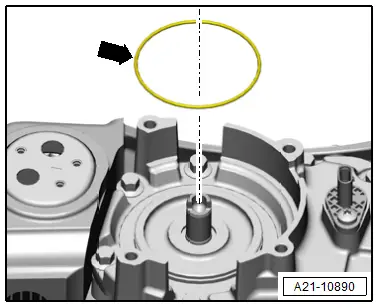

- Check that the coil spring -1- is seated correctly in the drive axle -2-.

- The drive axle must be free of oil and grease.

The following marks help with the allocation of the solenoid coupling driver to the supercharger shaft:

- Position the solenoid coupling drive plate so that the groove -4- for the coil spring alights with the arrow marking on the trim -3-.

- Position the supercharger so that the coil spring -2- points to the mark "KEY"-1-.

- Place the solenoid coupling drive plate -1- on the supercharger shaft -2--arrow-.

- With the power supply still switched on place the solenoid coupling on the supercharger and tighten the bolts -arrows-.

- With the power supply still switched on push the belt pulley by hand downward to the supercharger in direction of -arrow A- and at the same time tighten the clamping screw -arrow B-.

- Switch off the power supply, remove the Test Adapter for Compressor Module -VAS6909- from the solenoid coupling and from the power source.

- Install the coolant pipes to the supercharger. Refer to → Chapter "Supercharger Coolant Pipes, Removing and Installing".

Adapt the solenoid coupling after removing and installing or replacing:

- Connect the Vehicle Diagnostic Tester.

- Switch the ignition on.

- Select and start the Diagnostic operating mode.

- Select the Test plan tab.

- Select the button Individual tests and select the following tree structures one after the other:

- Drivetrain

- TFSI V6

- 01 - OBD-capable systems

- Simos Fuel Injection and Ignition

- Functions

- 01 - Supercharger clutch adaptation

Tightening Specifications

- Refer to → Chapter "Overview - Solenoid Coupling"