Audi Q7: Spring, Removing and Installing

Spring, Removing and Installing, Coil Spring

Special tools and workshop equipment required

- Pneumatic/Hydraulic Foot Pump -VAS6179-

- Spring Tensioning System -VAS6274-

- 30 mm long centering spring -5- from the Spring Tensioning System - Audi Set -VAS6274/10-

- Supplement Set VAS6274/12 -VAS6274/12-, not shown

Removing

- Remove the shock absorber. Refer to → Chapter "Shock Absorber, Removing and Installing".

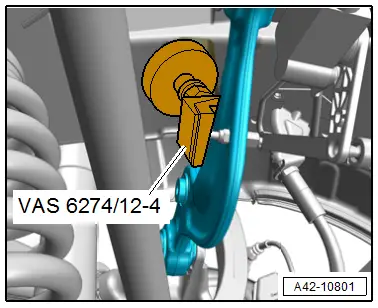

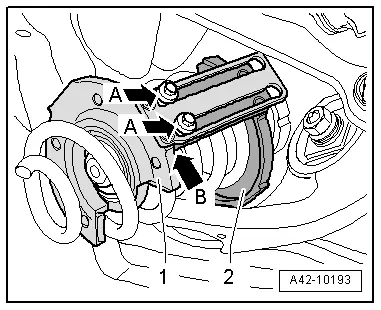

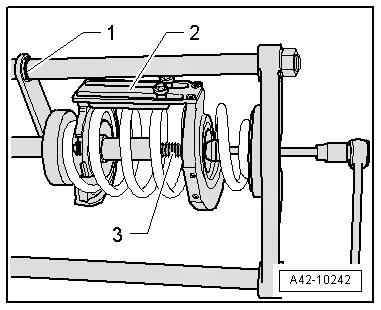

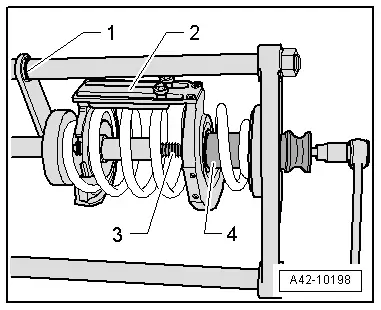

- Place the Supplement Set - Spreader Q7 -VAS6274/12-4- on the front transverse link, as shown.

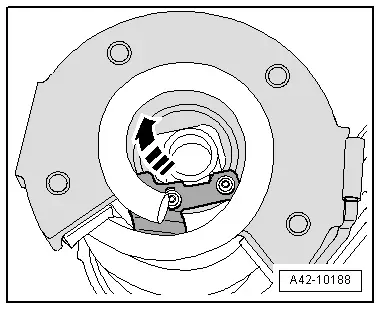

- Slide the securing lever back in the direction of -arrow- if necessary.

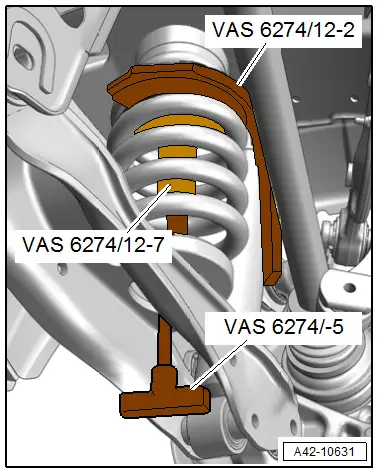

- Insert the Supplement Set - Thrust Plate With Securing Plate -VAS6274/12-2- from the supplement set from the outside, as shown.

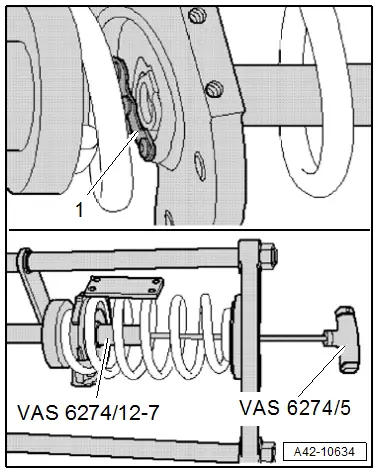

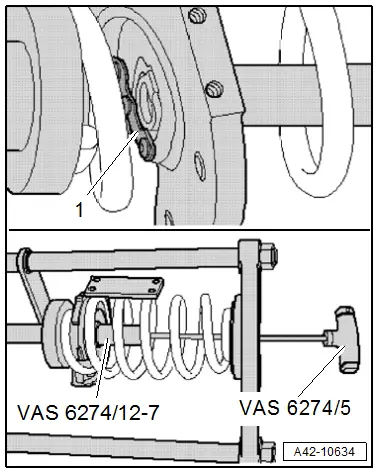

- Inset the Supplement Set - 89 mm Plunger -VAS6274/12-7- with the Spring Tensioning System - T-Bar -VAS6274/5- in the thrust plate. Slide the locking lever on the thrust plate back toward the outside (open).

- Press the locking lever in the direction of -arrow- to secure the piston.

- Turn the Supplement Set - Thrust Plate With Securing Plate -VAS6274/12-2- completely upward.

Caution

Caution

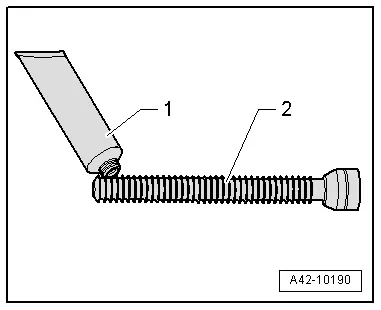

There is a risk of damaging the spindle due to missing or incorrect grease.

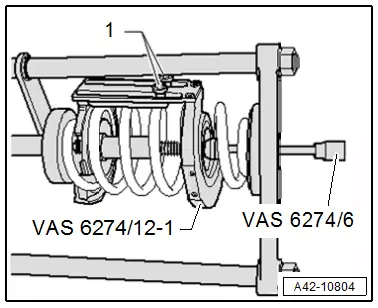

Coat the front area of the Spring Tensioning System - Audi Set - Spindle -VAS6274/10-4--Pos. 2- lightly with the accompanying grease -1- before removal and installation of each spring.

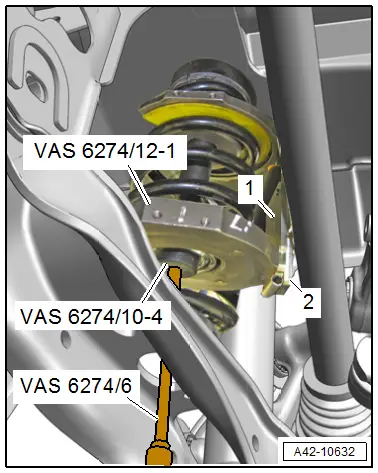

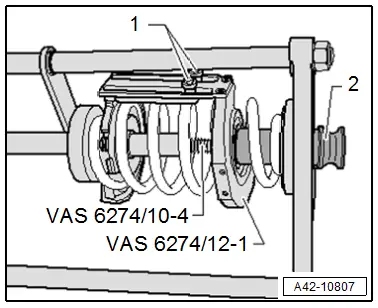

- Install the Supplement Set - Thrust Plate With Swivel Bearing - VAS6274/12-1- with the locking device brackets from the supplement set, as shown.

- The locking device brackets -1 and 2- from both thrust plates are parallel to each other.

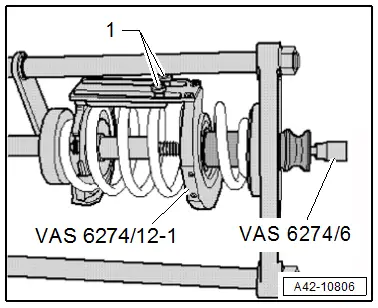

- Thinly grease the Spring Tensioning System - Audi Set -VAS6274/10-4- in the front area and install hand tight with the Spring Tensioning System - Socket -VAS6274/6-.

WARNING

WARNING

Risk of accident!

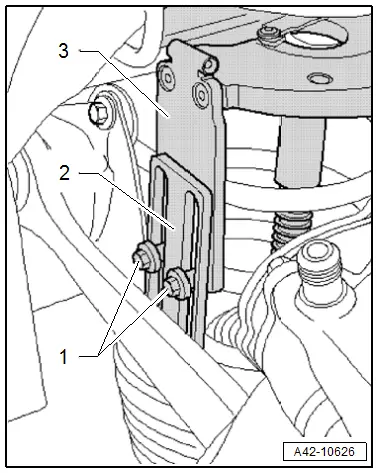

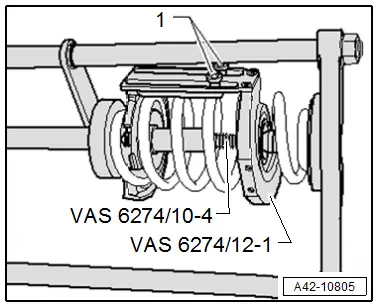

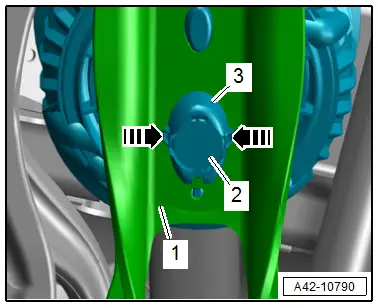

The coil spring may only be tensioned or released if both locking device brackets -2- and -3- are connected to each other using both bolts -1-.

- Install the bolts -1- for both the thrust plates locking device brackets -2 and 3- hand tight.

- Lightly tension the thrust plates using the Spring Tensioning System - Audi Set - Spindle -VAS6274/10-4-.

- Check if both coil springs are seated correctly in the pressure plates.

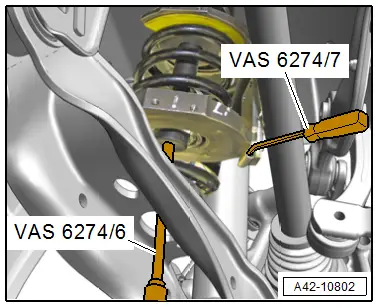

- Tension the coil spring with the Spring Tensioning System - Socket -VAS6274/6-, to do so counterhold with the Spring Tensioning System - Counterhold Tool -VAS6274/7-.

WARNING

WARNING

Risk of injury due to uneven tensioning of the coil springs.

- Do not use an impact wrench to tension the coil springs.

- Use a commercially available ratchet to tighten.

- Tension the coil spring until it can be removed.

Caution

Caution

There is a risk of damaging the spring tensioning system when tensioning.

- The bolts -A arrows- must not contact the stop of the Supplement Set - Thrust Plate With Securing Plate -VAS6274/12-2--1-.

- The locking device brackets from the Supplement Set - Thrust Plate With Securing Plate -VAS6274/12-1--2- must not contact the stop -arrow B- of the thrust plate.

- Remove the coil spring forward and down.

Release the Tension of the Coil Spring in the Spring Tensioning System -VAS6274-.

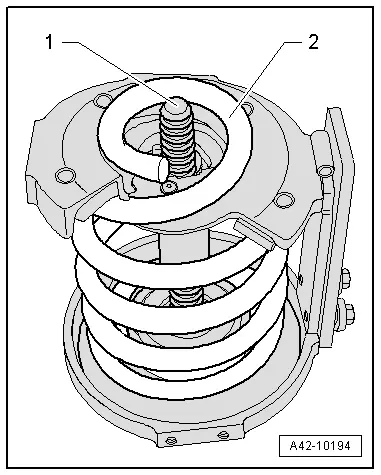

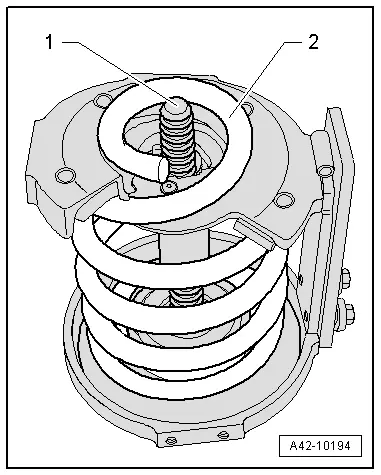

- Turn back the Spring Tensioning System - Audi Set - Spindle -VAS6274/10-4--1- slightly if necessary.

- The spindle must not project over the end of the coil spring -2-.

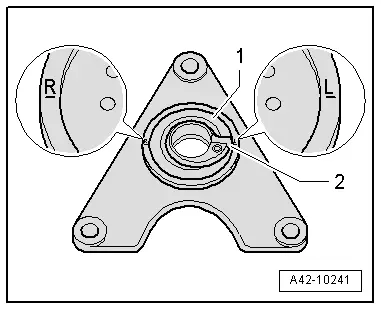

- Place the coil spring on the spring plate -1- so the stop -2- aligns with the corresponding mark.

Note

Note

The opposite mark applies to the Audi Q7 coil springs.

R - Left Side of Vehicle

L - Right Side of Vehicle

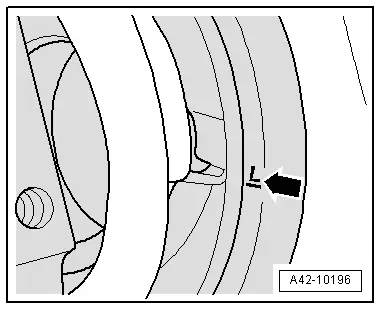

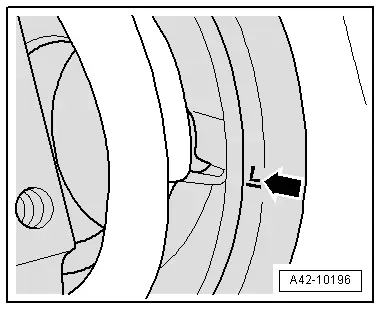

- Position the bottom of the coil spring in the Spring Tensioning System -VAS6274- at the -arrow- corresponding mark.

R - Left Side of Vehicle

L - Right Side of Vehicle

- Make a marking -1- with a waterproof felt-tip marker.

- The locking device -2- faces upward.

Note

Note

- The mark is needed when tightening for installation.

- Ignore -3-.

- Tighten the bolts -1- slightly by hand.

- Release the coil spring tension using the Spring Tensioning System - Socket -VAS6274/6-. Release the tension at the same time using the Spring Tensioning System -VAS6274- and the Pneumatic/Hydraulic Foot Pump -VAS6179-.

- After the tension on the coil spring is released, remove the Spring Tensioning System - Audi Set - Spindle -VAS6274/10-4-.

- Remove the locking device bolts -1- and the Supplement Set - Thrust Plate With Swivel Bearing -VAS6274/12-1-.

- Slide the locking lever -1- back.

- Remove the Supplement Set - 89 mm Plunger -VAS6274/12-7- with the Spring Tensioning System - T-Bar -VAS6274/5-.

- Release the coil spring completely.

Installing

Install in reverse order of removal and note the following:

- Insert the bottom of the coil spring in the Spring Tensioning System -VAS6274-. Refer to → Fig. "Coil spring and spring plate installation position" for the installation position.

- Position the coil spring in the Spring Tensioning System -VAS6274- at the -arrow- corresponding mark.

Note

Note

The opposite mark applies to the Audi Q7 coil springs.

R - Left Side of Vehicle

L - Right Side of Vehicle

- Insert the Supplement Set - Thrust Plate With Securing Plate -VAS6274/12-2- and install the Supplement Set - 89 mm Plunger -VAS6274/12-7- with the Spring Tensioning System - T-Bar - VAS6274/5-.

- Secure the piston with the securing lever -1-.

- Insert the Supplement Set - Thrust Plate With Securing Plate -VAS6274/12-1-.

- Install the locking device bolts -1- loosely.

- Insert the Spring Tensioning System - Audi Set - Spindle -VAS6274/10-4-.

- Install the 130 mm long centering spring -2- until stop.

- Tighten the locking device bolts -1- lightly by hand. The locking device must face upward when tightening the coil spring.

- Tension the coil spring using the Spring Tensioning System - Socket -VAS6274/6-. At the same time tension using the Spring Tensioning System -VAS6274- and the Pneumatic/Hydraulic Foot Pump -VAS6179-.

Caution

Caution

There is a risk of damaging the spring tensioning system when tensioning.

- The bolts from the locking device brackets must not contact the stop of the Supplement Set - Thrust Plate With Securing Plate -VAS6274/12-1-.

- The anti-twist mechanism bracket for the Supplement Set - Thrust Plate With Securing Plate -VAS6274/12-2- must also not lie on the stop for the Supplement Set - Thrust Plate With Securing Plate -VAS6274/12-1-.

- Only tighten the coil spring as far as the marking -1-. The locking device -2- must face up.

- When tensioning via the spindle -3-, make sure the centering sleeve -4- does not slip out of the Supplement Set - Thrust Plate With Securing Plate -VAS6274/12-1-.

- Release the Spring Tensioning System -VAS6274- and remove the coil spring with the tensioner.

- If necessary slightly re-tension the coil spring -2- via the Spring Tensioning System - Audi Set - Spindle -VAS6274/10-4--1-.

- The spindle must only project far enough over the coil spring that the upper spring plate can still rest completely on the coil spring.

- Bring the coil spring and the spring plate into the installation position. Refer to → Fig. "Coil spring and spring plate installation position".

- Install shock absorber. Refer to → Chapter "Shock Absorber, Removing and Installing".

- Tension the coil spring.

- Overview table for if an axle alignment is necessary. Refer to → Chapter "Need for Axle Alignment, Evaluating".

- Adjust the headlamps. Refer to → Electrical Equipment; Rep. Gr.94; Headlamps; Headlamp, Adjusting.

- Driver Assistance Systems Front Camera, Calibrating. Refer to → Chapter "Driver Assistance Systems Front Camera, Calibrating".

- Infrared System, Calibrating. Refer to → Chapter "Infrared System, Calibrating".

Spring, Removing and Installing, Air Spring

Special tools and workshop equipment required

- Torque Wrench 1331 5-50Nm -VAG1331-

- Torque Wrench 1332 40-200Nm -VAG1332-

Removing

Note

Note

Follow the guidelines for clean working conditions. Refer to → Chapter "Guidelines for Clean Working Conditions".

- Remove the air suspension system. Refer to → Chapter "Air Suspension System, Filling and Bleeding".

- Remove the rear wheel. Refer to → Chapter "Wheels and Tires".

- Remove the drive axle. Refer to → Chapter "Drive Axle, Removing and Installing".

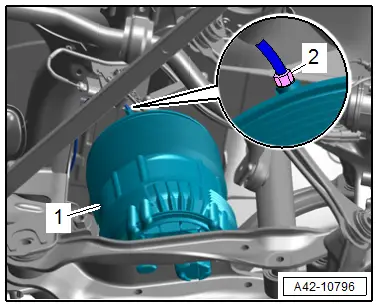

- Unclip the cap -2-.

- Release the catches in direction of -arrows- and free up the air spring -3- on the lower transverse link -1-.

- Remove the connecting piece -2- from the rear air spring.

Note

Note

If the connecting piece is removed separately (without the attached lines) check if the cutting ring has a loose components and is still in the threads and if necessary remove.

- Remove the air spring -1- downward.

Installing

Install in reverse order of removal and note the following:

- Air suspension system, filling. Refer to → Chapter "Air Suspension System, Filling and Bleeding".

Note

Note

- The vehicle may be removed from the vehicle hoist only after the air springs have been filled again.

- Before filling the air spring, check the installation position. Refer to → Fig. "Air Spring Installed Position".

- Readapt the standard vehicle height. Refer to → Chapter "Standard Vehicle Height, Readapting".

Tightening Specifications

- Refer to → Chapter "Overview - Suspension Strut, Shock Absorber and Spring, Air Spring"

- Refer to → Chapter "Wheels and Tires"