Audi Q7: Chain Drive

Overview - Camshaft Timing Chains

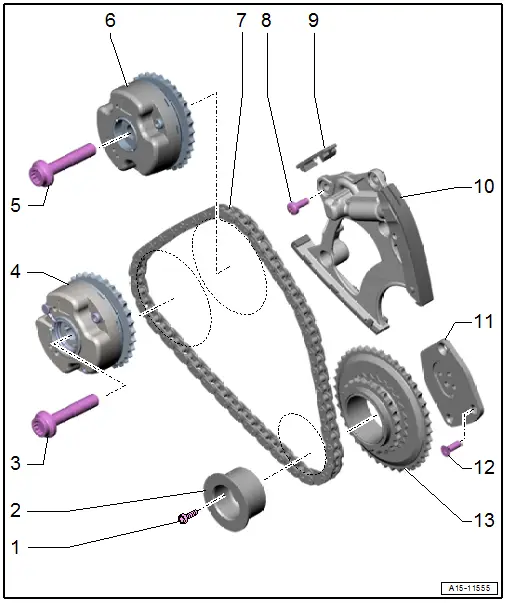

Left Camshaft Timing Chain

1 - Bolts

- Tightening specification. Refer to -item 4-

2 - Mounting Pin

- For the left camshaft timing chain drive chain sprocket

3 - Bolt

- 80 Nm +90º

- Replace after removing

4 - Camshaft Adjuster

- For the exhaust camshaft

- Designation "EX"

- Removing and installing. Refer to → Chapter "Camshaft Timing Chain, Removing from Camshafts".

5 - Bolt

- 80 Nm +90º

- Replace after removing

6 - Camshaft Adjuster

- For the intake camshaft

- Designation "IN"

- Removing and installing. Refer to → Chapter "Camshaft Timing Chain, Removing from Camshafts".

7 - Left Camshaft Timing Chain

- Mark the running direction with paint for reinstallation

- Removing from the camshafts. Refer to → Chapter "Camshaft Timing Chain, Removing from Camshafts".

- Removing and installing. Refer to → Chapter "Camshaft Timing Chain, Removing and Installing".

8 - Bolt

- 9 Nm

9 - Gliding Piece

10 - Chain Tensioner

- For the left camshaft timing chain

- Removing and installing. Refer to → Chapter "Camshaft Timing Chain, Removing and Installing".

11 - Bearing Plate

- For the drive chain sprocket

12 - Bolt

- Tightening specification. Refer to -item 8-

13 - Drive Chain Sprocket

- For the left camshaft timing chain

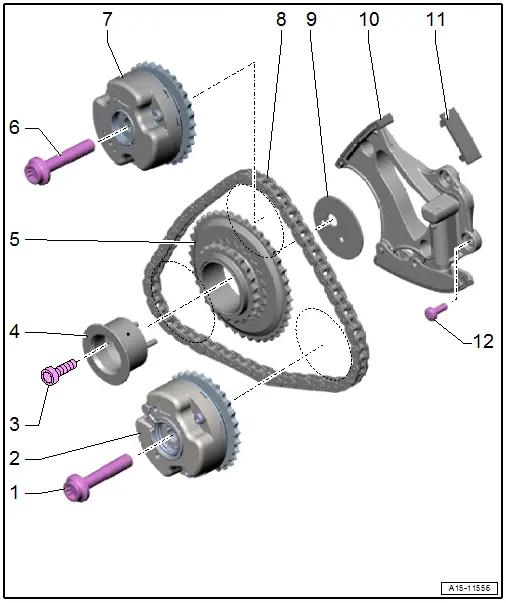

Right Camshaft Timing Chain

1 - Bolt

- 80 Nm +90º

- Replace after removing

2 - Camshaft Adjuster

- For the exhaust camshaft

- Designation "EX"

- Removing and installing. Refer to → Chapter "Camshaft Timing Chain, Removing from Camshafts".

3 - Bolt

- Tightening specification. Refer to -item 11-.

4 - Mounting Pin

- For the right camshaft timing chain drive chain sprocket

- Asymmetrical version

- Installation position. Refer to → Fig. "Mounting Pin for Right Camshaft Timing Chain Drive Chain Sprocket Installation Position".

5 - Drive Chain Sprocket

- For the right camshaft timing chain

- Installation position. Refer to → Fig. "Mounting Pin for Right Camshaft Timing Chain Drive Chain Sprocket Installation Position".

6 - Bolt

- 80 Nm +90º

- Replace after removing

7 - Camshaft Adjuster

- For the intake camshaft

- Designation "IN"

- Removing and installing. Refer to → Chapter "Camshaft Timing Chain, Removing from Camshafts".

8 - Right Camshaft Timing Chain

- Mark the running direction with paint for reinstallation

- Removing from the camshafts. Refer to → Chapter "Camshaft Timing Chain, Removing from Camshafts".

- Removing and installing. Refer to → Chapter "Camshaft Timing Chain, Removing and Installing".

9 - Thrust Washer

- For the right camshaft timing chain drive chain sprocket

- Asymmetrical version

- Installation position. Refer to → Fig. "Mounting Pin for Right Camshaft Timing Chain Drive Chain Sprocket Installation Position".

10 - Chain Tensioner

- For the right camshaft timing chain

- Removing and installing. Refer to → Chapter "Camshaft Timing Chain, Removing and Installing".

11 - Gliding Piece

12 - Bolt

- 9 Nm

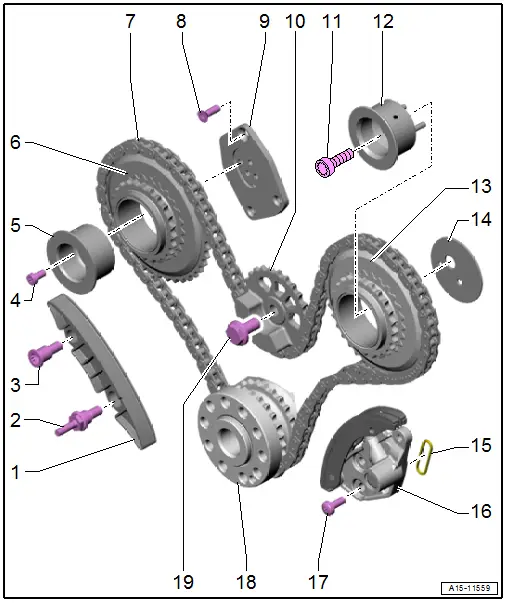

Overview - Timing Mechanism Drive Chain

1 - Guide Rail

2 - Bolt

- 16 Nm

3 - Bolt

- 16 Nm

4 - Bolts

- 5 Nm +90º

- Replace after removing

5 - Mounting Pin

- For the left camshaft timing chain drive chain sprocket

6 - Drive Chain Sprocket

- For the left camshaft timing chain

7 - Drive Chain

- For timing mechanism

- Mark the running direction with paint for reinstallation

- Removing and installing. Refer to → Chapter "Timing Mechanism Drive Chain, Removing and Installing".

8 - Bolt

- 8 Nm +45º

- Replace after removing

9 - Bearing Plate

- For the left camshaft timing chain drive chain sprocket

10 - Balance Shaft Chain Sprocket

- With transmission side balance weight

11 - Bolt

- 30 Nm +90º

12 - Mounting Pin

- For the right camshaft timing chain drive chain sprocket

- Asymmetrical version

- Installation position. Refer to → Fig. "Mounting Pin for Right Camshaft Timing Chain Drive Chain Sprocket Installation Position".

13 - Drive Chain Sprocket

- For the right camshaft timing chain

- Installation position. Refer to → Fig. "Mounting Pin for Right Camshaft Timing Chain Drive Chain Sprocket Installation Position".

14 - Thrust Washer

- For the right camshaft timing chain drive chain sprocket

- Asymmetrical version

- Installation position. Refer to → Fig. "Mounting Pin for Right Camshaft Timing Chain Drive Chain Sprocket Installation Position".

15 - Seal

- Replace after removing

16 - Chain Tensioner

- Removing and installing. Refer to → Chapter "Timing Mechanism Drive Chain, Removing and Installing".

17 - Bolt

- 9 Nm

18 - Crankshaft

19 - Bolt

- Tightening specification. Refer to -item 2-.

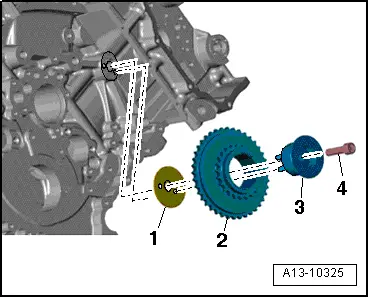

Mounting Pin for Right Camshaft Timing Chain Drive Chain Sprocket Installation Position

- The alignment pins in the right camshaft timing chain drive chain sprocket mounting pin -3- must engage in the holes in the thrust washer -1- and in the cylinder block.

2 - Drive Chain Sprocket for Right Camshaft Timing Chain

4 - Bolt

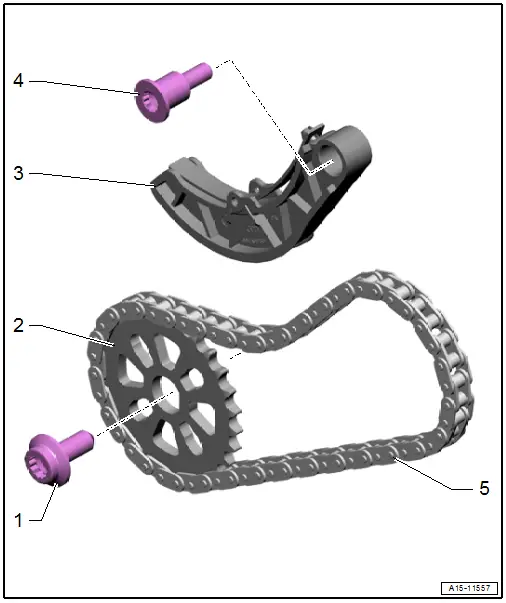

Overview - Oil Pump Drive Chain

1 - Bolt

- 30 Nm +90º

- Replace after removing

2 - Drive Chain Sprocket

- For the oil pump

- Installed position: the side with the lettering faces the transmission

- Installation only possible in one position.

3 - Chain Tensioner

- With glide rail

4 - Bolt

- 20 Nm

5 - Drive Chain

- For the oil pump

- Mark the running direction with paint for reinstallation

- Removing and installing. Refer to → Chapter "Oil Pump Drive Chain, Removing and Installing".