Audi Q7: Overview - Subframe

Audi Q7 (4M) 2016-2026 Workshop Manual / Chassis / Suspension, Wheels, Steering / Front Suspension / Overview - Subframe

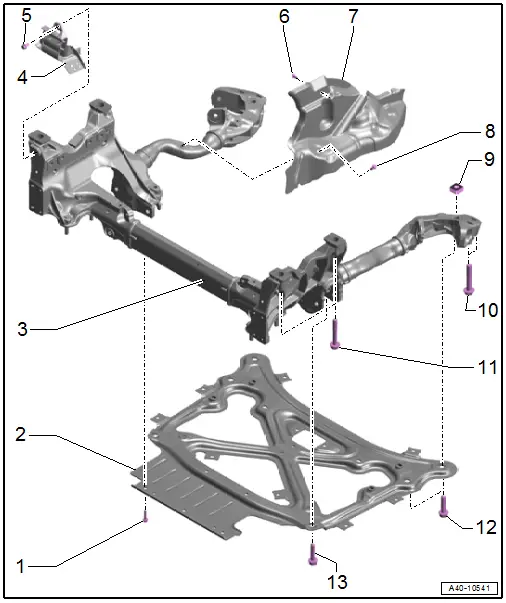

Subframe

Caution

Caution

There is a risk of damaging the threads on the subframe threaded connection to the body.

- The subframe bolts on the body must not be loosened or tightened with an impact wrench.

- Always install all bolts by hand for the first few turns.

1 - Bolt

- 20 Nm

2 - Subframe Crossbrace

- Removing and installing. Refer to → Chapter "Subframe Crossbrace, Removing and Installing".

Caution

Caution

There is a risk of damaging the suspension components.

- If the subframe mount, steering gear or subframe crossbrace are not installed correctly, do not rest the vehicle on its wheels.

- Supporting the vehicle at the subframe or the subframe crossbrace (for example, using a floor jack or similar device) is not permitted.

3 - Subframe

- Securing. Refer to → Chapter "Subframe, Securing".

- Lowering. Refer to → Chapter "Subframe, Lowering".

- Removing and installing. Refer to → Chapter "Subframe with Steering Gear, Removing and Installing".

Note

Note

Perform a pre-adjustment on the subframe if it is being replaced or if it had to be removed in order to loosen the crossbrace. Refer to → Fig. "Pre-Adjustment of the Subframe:".

4 - Bracket

- For the electrical wiring harness

5 - Bolt

- 9 Nm

6 - Bolt

- 9 Nm

7 - Shield

- There are different versions. Refer to the Parts Catalog.

- Removing and installing. Refer to → Chapter "Subframe Shield, Removing and Installing".

8 - Bolt

- 9 Nm

9 - Square Nut

10 - Bolt

- 130 Nm +180º

- Replace after removing

- Remove and tighten together with -11- diagonally in steps

11 - Bolt

- 115 Nm +90º

- Replace after removing

- Remove and tighten together with -10- diagonally in steps

12 - Bolt

- 90 Nm +135º

- 42 mm long

- Replace after removing

13 - Bolt

- 90 Nm +90º

- Replace after removing

- 51 mm long

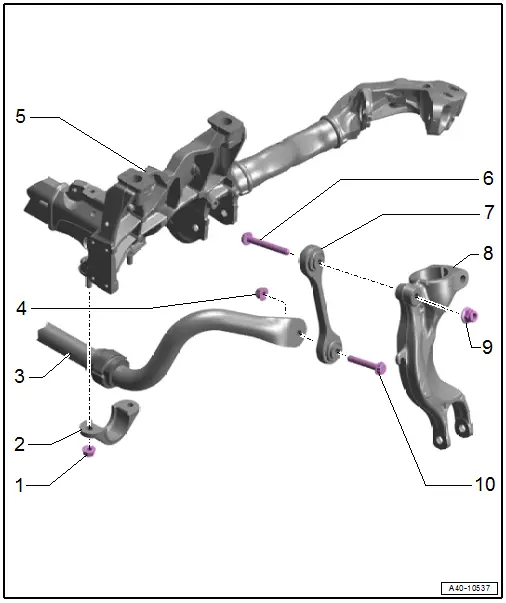

Stabilizer Bar

1 - Nut

- 50 Nm

- Replace after removing

- Remove and tighten evenly alternating from side to side.

2 - Clamp

3 - Stabilizer Bar

- With rubber bushing

- The rubber bushing cannot be replaced separately

- Removing and installing. Refer to → Chapter "Stabilizer Bar, Removing and Installing".

4 - Nut

- 40 Nm +90º

- Replace after removing

5 - Subframe

6 - Bolt

- Replace after removing

7 - Coupling Rod

- Removing and installing. Refer to → Chapter "Coupling Rod, Removing and Installing".

8 - Shock Absorber Fork

- Removing and installing. Refer to → Chapter "Shock Absorber Fork, Removing and Installing".

9 - Nut

- 40 Nm +90º

- Replace after removing

10 - Bolt

- Replace after removing