Audi Q7: Engine Oil Cooler

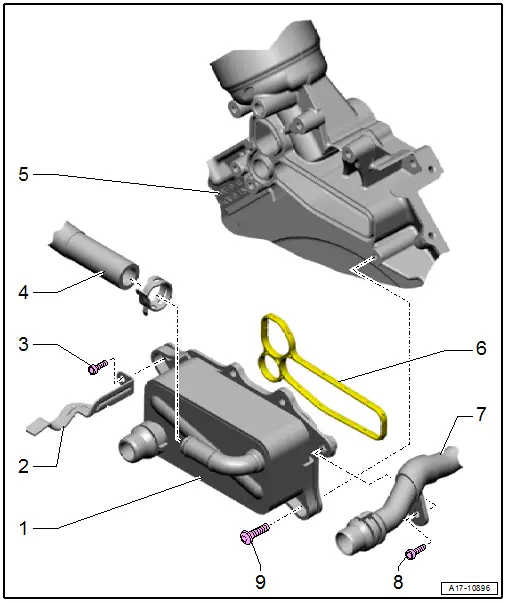

Overview - Engine Oil Cooler

1 - Engine Oil Cooler

- With oil cooler bypass valve

- See note.

- Removing and installing. Refer to → Chapter "Engine Oil Cooler, Removing and Installing".

2 - Bracket

3 - Bolt

- 3 Nm +90Âş

- Replace after removing

4 - Coolant Hose

5 - Lower Timing Chain Cover

6 - Seal

- Replace after removing

7 - Upper Coolant Pipe

- Removing and installing. Refer to → Chapter "Upper Coolant Pipe, Removing and Installing".

8 - Bolt

- Tightening specification. Refer to -item 19-.

9 - Bolt

- 3 Nm +90Âş

- Replace after removing

Engine Oil Cooler, Removing and Installing

Special tools and workshop equipment required

- Hose Clip Pliers -VAS6362-

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- Bolts - Engine oil cooler

- Seal - Engine oil cooler

Removing

- Drain the coolant. Refer to → Chapter "Coolant, Draining and Filling".

- Remove the Coolant Recirculation Pump -V50- with bracket. Refer to → Chapter "Coolant Recirculation Pump -V50-, Removing and Installing".

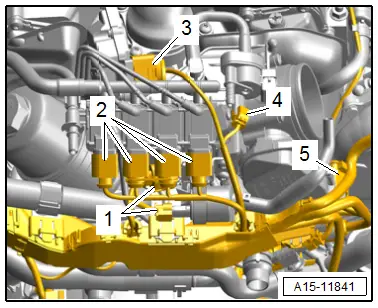

- Disconnect the connectors -1 to 5- and free them up.

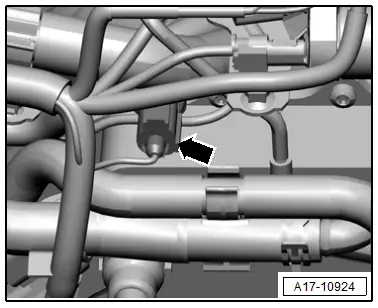

- Disconnect the connector -arrow- for the Oil Pressure Switch -F22- and free up the wire.

- Disconnect the connectors -1 through 5- and remove them from the bracket.

- Free up the wiring harness.

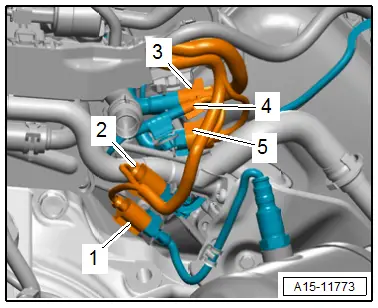

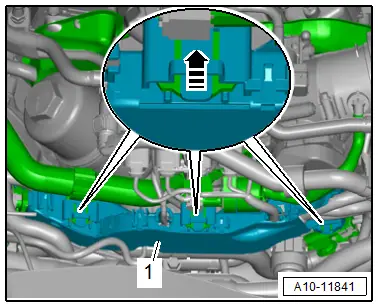

- Release the catches in direction of -arrow-, remove the wiring duct -1- toward the rear and push to the side.

- Push the wires and hoses to the side.

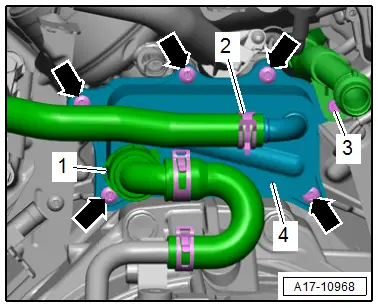

- Lift the clamp -1-, loosen the hose clamp -2- and remove the coolant hoses.

- Remove the bolts -3 and arrows- and remove the engine oil cooler -4- to the left side.

Installing

Install in reverse order of removal and note the following:

Note

Note

- Replace the bolts that were tightened with an additional turn after removing them.

- Replace the seal after removal.

- Secure all hose connections with hose clamps that match the ones used in series production. Refer to the Parts Catalog.

- Connections and wire routing. Refer to → Wiring diagrams, Troubleshooting & Component locations.

- Connect the coolant hoses with the connector coupling. Refer to → Fig. "Connect the Coolant Hose to the Connector Coupling".

Note

Note

Used coolant cannot be used again.

- Fill with coolant.

Tightening Specifications

- Refer to → Chapter "Overview - Oil Pan/Oil Pump"

- Refer to → Chapter "Overview - Electric Coolant Pump"