Audi Q7: Oil Filter/Oil Pressure Switch

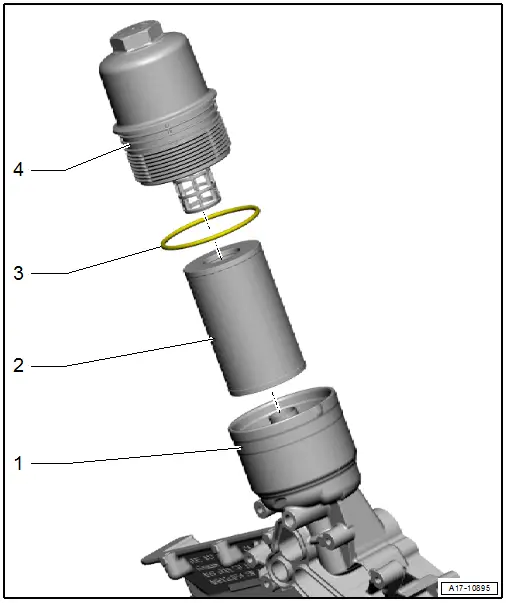

Overview - Oil Filter

1 - Oil Filter Housing

- With filter bypass valve

- With oil drain valve

- One unit with the lower timing chain cover

2 - Oil Filter Element

- Removing and installing.

3 - Gasket

4 - Cap

- 25 Nm

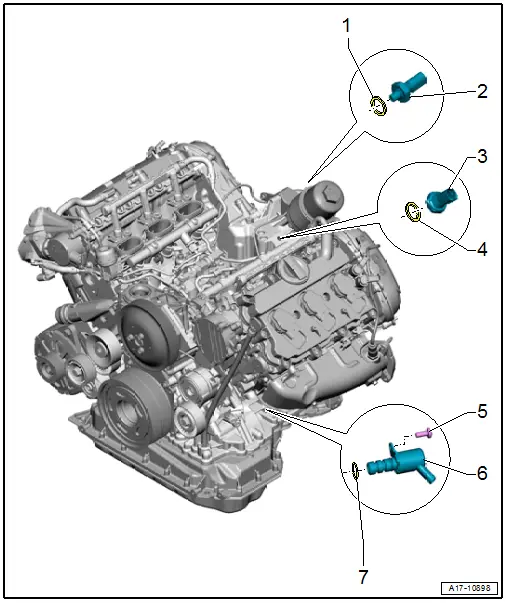

Overview - Oil Pressure Switch/Oil Pressure Regulation Valve

1 - Gasket

- Replace after removing

2 - Oil Pressure Switch -F22-

- 20 Nm

- Switching pressure 2.5 to 3.2 bar (36.25 to 46.41 psi) (oil pump high pressure side)

- Black insulation

- Checking using Vehicle Diagnostic Tester.

- Removing and installing. Refer to → Chapter "Oil Pressure Switch -F22-, Removing and Installing".

3 - Reduced Oil Pressure Switch -F378-

- 20 Nm

- Switching pressure 0.75 to 1.05 bar (10.87 to 15.22 psi) (oil pump low pressure side)

- Light gray insulation

- Checking using Vehicle Diagnostic Tester.

- Removing and installing. Refer to → Chapter "Reduced Oil Pressure Switch -F378-, Removing and Installing".

4 - Gasket

- Replace after removing

5 - Bolt

- 9 Nm

6 - Oil Pressure Regulation Valve -N428-

- Checking using the Vehicle Diagnostic Tester.

- Removing and installing. Refer to → Chapter "Oil Pressure Regulation Valve -N428-, Removing and Installing".

7 - O-Ring

- Replace after removing

Oil Pressure Switch -F22-, Removing and Installing

Special tools and workshop equipment required

- Socket and Jointed Extension - 24mm -T40175-

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- Gasket - Oil pressure switch

Removing

- Remove the air filter housing. Refer to → Chapter "Air Filter Housing, Removing and Installing".

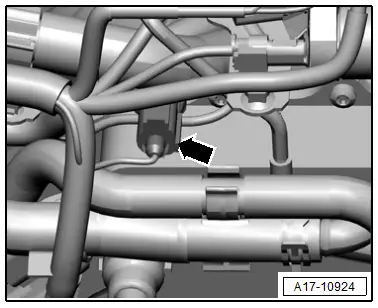

- Release the catches in direction of -arrow-, remove the wiring duct -1- toward the rear and push it slightly upward.

- Free up the wire and hoses and push to the side.

Note

Note

To collect escaping engine oil, place a clean cloth under oil filter housing.

- Disconnect the connector -arrow-.

- Remove the Oil Pressure Switch -F22- using the Socket and Jointed Extension - 24mm -T40175-.

Installing

Install in reverse order of removal and note the following:

Note

Note

- Replace the gasket after removal.

- To prevent engine oil loss, insert the new Oil Pressure Switch -F22- into the hole immediately.

- Install the air filter housing. Refer to → Chapter "Air Filter Housing, Removing and Installing".

- Check the oil level.

Tightening Specifications

- Refer to → Chapter "Overview - Oil Pressure Switch/Oil Pressure Regulation Valve"

Reduced Oil Pressure Switch -F378-, Removing and Installing

Special tools and workshop equipment required

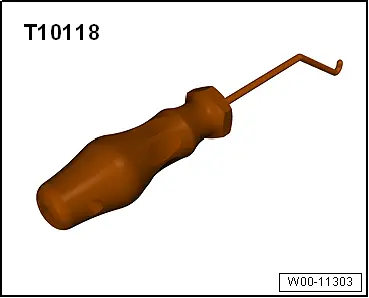

- Elbow Assembly Tool -T10118-

- Socket and Jointed Extension - 24mm -T40175-

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- Gasket - Reduced oil pressure switch

Removing

- Remove the supercharger. Refer to → Chapter "Supercharger, Removing and Installing".

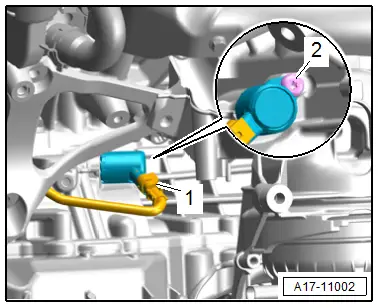

- Disconnect the electrical connector -2- using the Elbow Assembly Tool -T10118-.

- Remove the Reduced Oil Pressure Switch -F378--1- with a Socket and Jointed Extension - 24mm -T40175-.

Installing

Install in reverse order of removal and note the following:

Note

Note

Replace the gasket after removal.

- Install the supercharger. Refer to → Chapter "Supercharger, Removing and Installing".

Tightening Specifications

- Refer to → Chapter "Overview - Oil Pressure Switch/Oil Pressure Regulation Valve"

Oil Pressure, Checking

Special tools and workshop equipment required

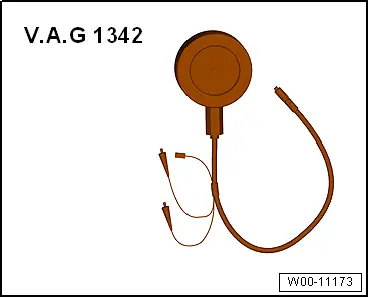

- Oil Pressure Gauge Kit -VAG1342-

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- Gasket - Oil pressure switch

Procedure

- Oil level OK

- Engine oil temperature approximately 80 ºC (176 ºF)

- Remove the Oil Pressure Switch -F22-. Refer to → Chapter "Oil Pressure Switch -F22-, Removing and Installing".

- Connect the Oil Pressure Gauge Kit -VAG1342- in the opening for the oil pressure switch.

- Install the Oil Pressure Switch -F22- in the oil pressure tester.

- Start the engine.

- Oil pressure when the vehicle is idling is minimum 1.2 bar (17.4 psi).

- Oil pressure at 2,000 RPM is minimum 1.5 bar (21.75 psi).

Assembling

- Install the Oil Pressure Switch -F22-. Refer to → Chapter "Oil Pressure Switch -F22-, Removing and Installing".

Oil Pressure Regulation Valve -N428-, Removing and Installing

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- O-ring - Oil pressure regulation valve

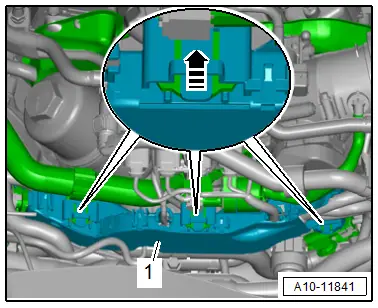

Removing

- Remove the front noise insulation. Refer to → Body Exterior; Rep. Gr.66; Noise Insulation; Noise Insulation, Removing and Installing.

- Remove the ribbed belt from the A/C compressor. Refer to → Chapter "Ribbed Belt, Removing and Installing, Sub-Assembly Ribbed Belt".

- Remove the A/C compressor from the bracket and tie it up toward the front. Refer to → Heating, Ventilation and Air Conditioning; Rep. Gr.87; A/C Compressor; A/C Compressor, Removing and Installing at Bracket.

- Remove the left subframe shield and push it slightly to the side. Refer to → Suspension, Wheels, Steering; Rep. Gr.40; Subframe; Subframe Shield, Removing and Installing.

- Disconnect the connector -1-.

Note

Note

Lay a cloth below to catch the draining engine oil.

- Remove the bolt -2-, and remove the Oil Pressure Regulation Valve -N428-.

Installing

Install in reverse order of removal and note the following:

Note

Note

Replace the O-ring after removing.

- Install the ribbed belt. Refer to → Chapter "Ribbed Belt, Removing and Installing, Sub-Assembly Ribbed Belt".

Tightening Specifications

- Refer to → Chapter "Overview - Oil Pressure Switch/Oil Pressure Regulation Valve"

- Refer to → Suspension, Wheels, Steering; Rep. Gr.40; Subframe; Overview - Subframe.

- Refer to → Heating, Ventilation and Air Conditioning; Rep. Gr.87; A/C Compressor; Overview - A/C Compressor Power Unit.

- Refer to → Body Exterior; Rep. Gr.66; Noise Insulation; Overview - Noise Insulation.

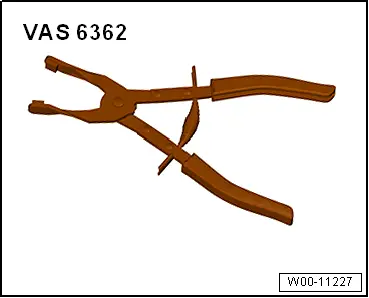

Special Tools

Special tools and workshop equipment required

- Elbow Assembly Tool -T10118-

- Socket and Jointed Extension - 24mm -T40175-

- Oil Pressure Gauge Kit -VAG1342-

- Hose Clip Pliers -VAS6362-