Audi Q7: Overview - Suspension Strut, Shock Absorber and Spring

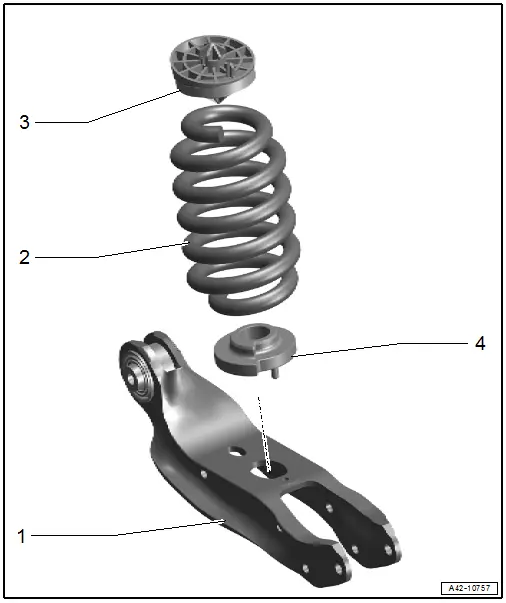

Overview - Suspension Strut, Shock Absorber and Spring, Coil Spring

Coil Spring

1 - Rear Lower Transverse Link

- Removing and installing. Refer to → Chapter "Rear Lower Transverse Link, Removing and Installing".

2 - Coil Spring

- Removing and installing. Refer to → Chapter "Spring, Removing and Installing, Coil Spring".

- Installation position. Refer to → Fig. "Coil spring and spring plate installation position".

3 - Upper Spring Support

- Installation position. Refer to → Fig. "Coil spring and spring plate installation position".

4 - Lower Spring Support

- Installation position. Refer to → Fig. "Coil spring and spring plate installation position".

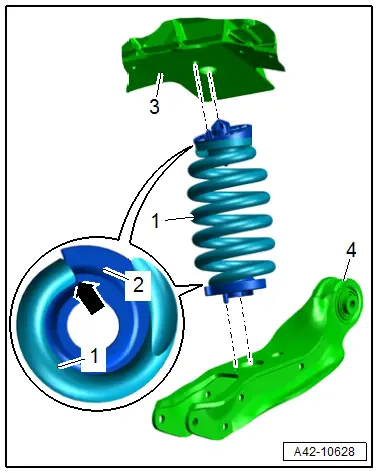

Coil spring and spring plate installation position

- The end of the spring -1- must be positioned to the spring plate -2- until stop -arrow-.

- The positioning pins of the spring plate must engage at the top in the holes in the body -3- and below in the holes in the rear transverse link -4- as shown.

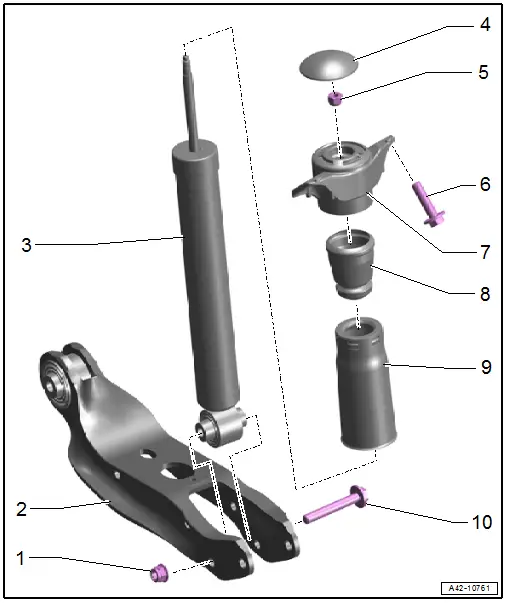

Shock Absorber

1 - Nut

- 70 Nm +180º

- Replace after removing

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing at Standard Vehicle Height, Lifting Vehicles with Air Suspension".

2 - Rear Lower Transverse Link

- Removing and installing. Refer to → Chapter "Rear Lower Transverse Link, Removing and Installing".

3 - Shock Absorber

- Because of different shock absorber valve systems, only install new shock absorbers from the same manufacturer on both axles, if possible.

- Removing and installing. Refer to → Chapter "Shock Absorber, Removing and Installing".

4 - Protective Cap

- There are different versions. Refer to the Parts Catalog for the allocation.

5 - Nut

- 35 Nm

6 - Bolt

- 50 Nm +90º

- Replace after removing

7 - Shock Absorber Mount

8 - Spring

9 - Protective Cover

- Installed in the groove on the spring

10 - Bolt

- Replace after removing

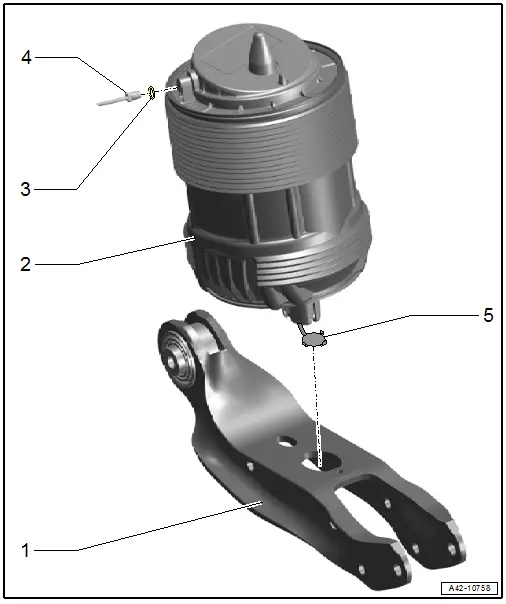

Overview - Suspension Strut, Shock Absorber and Spring, Air Spring

1 - Rear Lower Transverse Link

2 - Air Spring

- Removing and installing. Refer to → Chapter "Spring, Removing and Installing, Air Spring".

- Installation position. Refer to → Fig. "Air Spring Installed Position".

3 - O-Ring

- If sealing ring is leaking nip open and replace.

4 - Air Line

- If the connecting piece is removed separately (without the attached lines) check if the cutting ring has a loose components is still in the threads and if necessary remove.

- Connecting piece tightening specification. Refer to → Chapter "Overview - Air Lines".

5 - Retainer

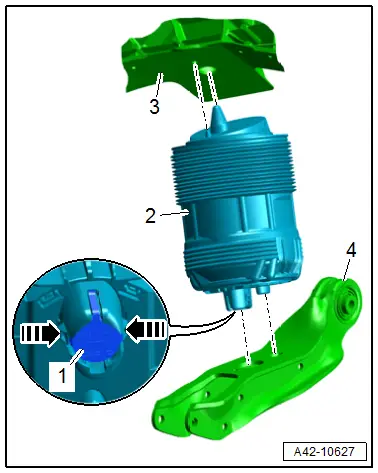

Air Spring Installed Position

- When filling the air suspension system check the installation position of the air suspension system:

- The positioning pins of the air spring -2- must engage at the top in the holes in the body -3- and below in the holes in the rear transverse link -4- as shown.

- The catches in direction of -arrows- must engage audibly in the rear lower transverse link.

- The catches must engage with the retainer -1-.

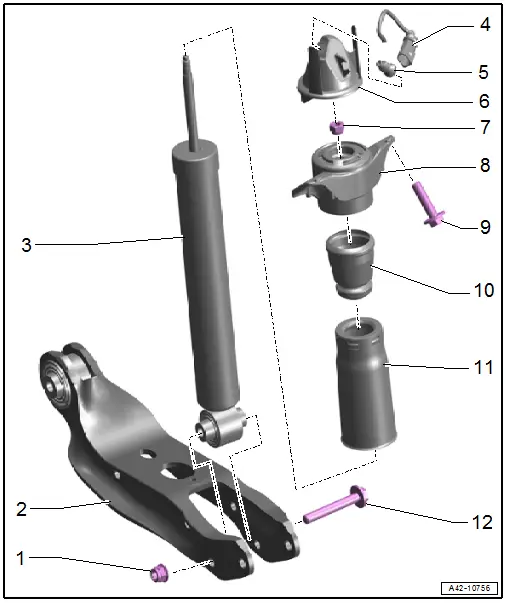

Shock Absorber

1 - Nut

- Tightening specification. Refer to -item 12-

2 - Rear Lower Transverse Link

- Removing and installing. Refer to → Chapter "Rear Lower Transverse Link, Removing and Installing".

3 - Shock Absorber

- Because of different shock absorber valve systems, only install new shock absorbers from the same manufacturer on both axles, if possible.

- Removing and installing. Refer to → Chapter "Shock Absorber, Removing and Installing".

4 - Connector

5 - Grommet

6 - Protective Cap

7 - Nut

- 35 Nm

8 - Shock Absorber Mount

9 - Bolt

- 50 Nm +90º

- Replace after removing

10 - Spring

11 - Protective Cover

- Installed in the groove on the spring

12 - Bolt

- Replace after removing