Audi Q7: Boot, Replacing

Special tools and workshop equipment required

- Torque Wrench 1410 -VAG1410-

- Clampling Pliers -VAG1682A-

Removing

- Remove the shock absorber fork. Refer to → Chapter "Shock Absorber Fork, Removing and Installing".

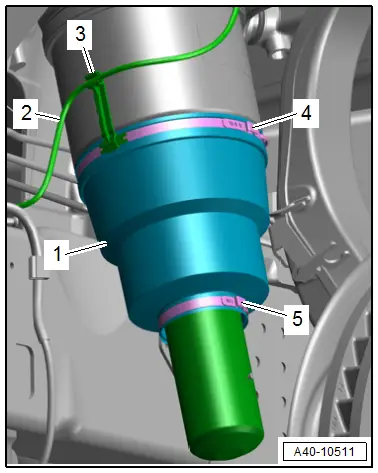

- Free up the air line -2- on the bracket -3-.

- Remove the clamps -4 and 5-.

- Remove the boot -1- carefully from the upper collars on the suspension strut housing as well as from the lower collar of the rolling piston and from the air spring.

Visual Inspection

Note

Note

Check the surface of the rolling piston and the rubber boot for damage and dirt before installing.

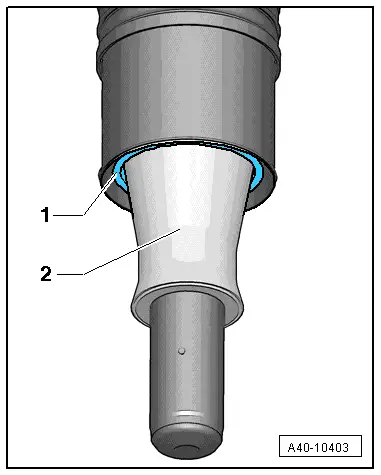

- Check the rubber boot -1- for damage.

- The boot must be regular and uniform.

- Replace the air spring if damaged.

- Check the rolling piston -2- for damage and debris.

- If necessary rework the surface with sand paper. Be careful not to make any grooves or scrapes.

Installing

Install in reverse order of removal and note the following:

- Install the shock absorber fork. Refer to → Chapter "Shock Absorber Fork, Removing and Installing".

- Pay attention to the installation position of the boot. Refer to → Fig. "Boot Installation Position".

- Before tensioning clamps, make sure boot is not twisted.

- Tension the clamp using the Clampling Pliers -VAG1682A-. Refer to → Fig. "Tension the Clamp on the Air Spring.".

Suspension Strut, Filling

Special tools and workshop equipment required

- Air Suspension Strut Charger -VAS6231-

- Air Spring Strut Adapter -T10157-

- Steel gas bottle filled with argon or corgon

Note

Note

Air springs are supplied as replacement parts with a minimum pressure. By sitting in storage for extended periods this pressure can diminish (just like a tire). This minimum pressure must be checked and if necessary restored by "recharging" before the air spring is removed from the packaging. If air spring is removed from the packaging without this checking/recharging, this may cause indentations or kinks to form in the dust boot before it reaches its normal shape. These folds can cause damage and premature failure of the air spring.

Procedure

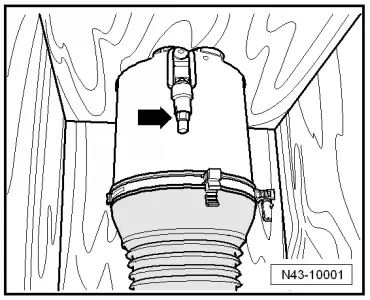

- Remove plug -arrow- from the residual pressure retaining valve.

- Close the valve of the steel gas bottle.

- Become familiar with the relevant rules for the prevention of accidents for pressurized containers and technical gases.

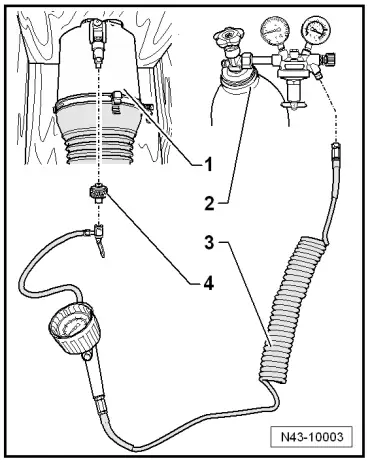

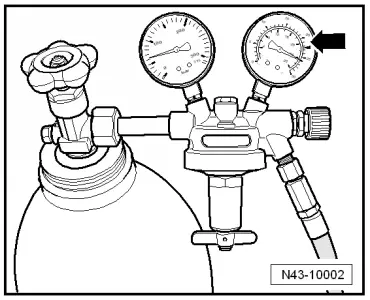

- Connect the Air Suspension Strut Charger -VAS6231- and Air Spring Strut Adapter -T10157- as shown.

1 - Air spring in the packaging.

2 - Steel gas bottle for argon, corgon with gauges

3 - Air Suspension Strut Charger -VAS6231-

4 - Air Spring Strut Adapter -T10157-

Note

Note

"Refilling" the air spring may only be performed with the gases from the top to prevent any "uncleaned" air from getting into the air suspension system.

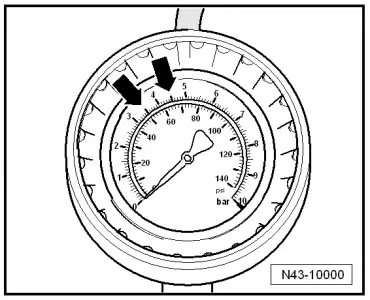

- Set the flow rate limiter gauge on the fitting to 2.0 L/min -arrow-.

- Fill the air spring fill the gas into air spring damper approximately to 5.0 bar (72.51 psi).

- Disconnect the Air Suspension Strut Charger -VAS6231- from the Air Spring Strut Adapter -T10157-. When doing this, gas will escape at a pressure greater than 3.5 bar (50.76 psi).

- Minimum pressure is now reestablished. The air spring can be removed from the packaging.

- After installation, first drive the vehicle at high ride height and then at normal ride height.

- Repeat the procedure.

Note

Note

By moving the vehicle lever heights twice, the majority of the gas is exchanged with filtered and dried air from the air supply motor.

- Install the air spring.

Shock Absorber Fork, Removing and Installing

Special tools and workshop equipment required

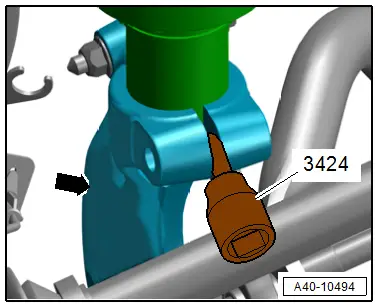

- Spreader Tool -3424-

- Torque Wrench 1331 5-50Nm -VAG1331-

- Torque Wrench 1332 40-200Nm -VAG1332-

- Engine and Gearbox Jack -VAS6931-

- Engine/Gearbox Jack Adapter - Wheel Hub Support -T10149-

Removing

Before starting work:

- Versions with coil springs: determine the curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring".

- Versions with air suspension: determine the standard vehicle height. Refer to → Chapter "Wheel Bearing at Standard Vehicle Height, Lifting Vehicles with Air Suspension".

- Remove the front wheel. Refer to → Chapter "Wheels and Tires".

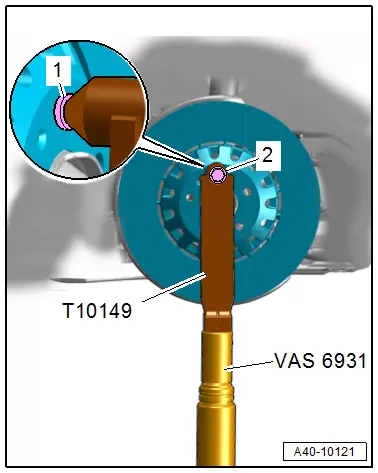

- Turn the wheel hub, until the wheel bolt hole is on top.

Caution

Caution

Risk of destroying the wheel bearing when installing the wheel bolt.

So that the installed wheel bolt cannot push against the wheel bearing, it (the bolt) must be installed with a washer inserted in between.

- Install the Engine/Gearbox Jack Adapter - Wheel Hub Support -T10149- with a wheel bolt -2- and inserted washer -1- on the wheel hub.

- Slightly lift the wheel bearing housing using the Engine/Gearbox Jack Adapter - Wheel Hub Support -T10149- with the Engine and Gearbox Jack -VAS6931- this allows the threaded connections to easily separate.

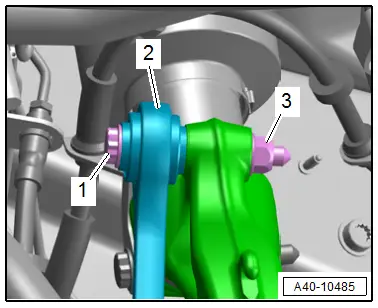

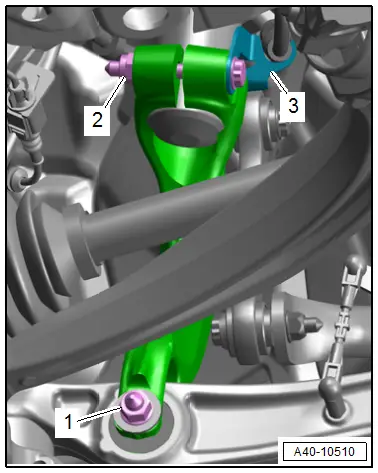

- Remove the nut -3- and the bolt -1- for the coupling rod -2-.

- Remove the engine and the transmission.

- Disconnect the connectors -1 and 2- for the shock absorber fork.

- Push the bracket -3- with the brake hose to the side.

- Insert the Spreader Tool -3424- into the slot in the shock absorber fork -arrow-.

Caution

Caution

There is a risk of damaging the ball joint.

The upper control arm ball joint must not be bent past the maximum attachment point.

- Remove the shock absorber fork downward from the shock absorber tube and remove, at the same time push the wheel bearing housing carefully downward.

Installing

Install in reverse order of removal and note the following:

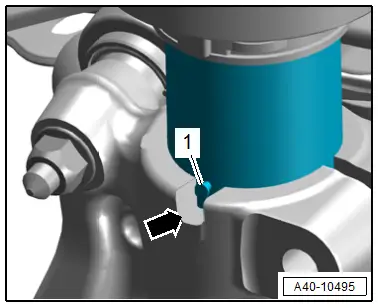

- Attach the shock absorber fork.

- The T-pin -1- of the suspension strut must engage in the groove -arrow- on the shock absorber fork.

- Install the threaded connections for the components with bonded rubber bushings only until stop but do not yet tighten.

Note

Note

Bonded rubber bushings have a limited range of motion. Only tighten suspension bolts when vehicle is in curb weight position or at standard vehicle height.

- Lifting the wheel bearing in curb weight position (refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring") or at standard vehicle height (refer to → Chapter "Wheel Bearing at Standard Vehicle Height, Lifting Vehicles with Air Suspension").

- Overview table for if an axle alignment is necessary. Refer to → Chapter "Need for Axle Alignment, Evaluating".

Tightening Specifications

- Refer to → Chapter "Overview - Suspension Strut and Upper Control Arm"

- Refer to → Chapter "Overview - Lower Control Arm and Ball Joint"

- Refer to → Chapter "Wheels and Tires"