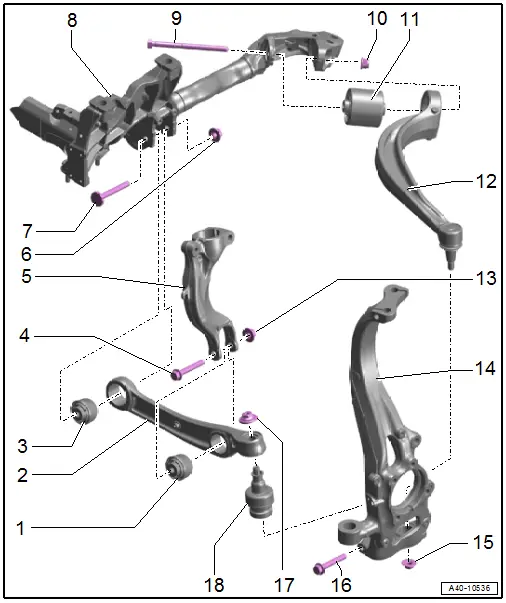

Audi Q7: Overview - Lower Control Arm and Ball Joint

Audi Q7 (4M) 2016-2026 Workshop Manual / Chassis / Suspension, Wheels, Steering / Front Suspension / Overview - Lower Control Arm and Ball Joint

1 - Wheel Bearing Housing Side Bonded Rubber Bushing

- Replacing. Refer to → Chapter "Control Arm Ball Bearing, Replacing, Wheel Bearing Housing Side".

2 - Control Arm

- Removing and installing. Refer to → Chapter "Control Arm, Removing and Installing".

3 - Subframe Side Bonded Rubber Bushing

- Replacing. Refer to → Chapter "Control Arm Ball Bearing, Replacing, Subframe Side".

4 - Bolt

- Replace after removing

5 - Shock Absorber Fork

- Removing and installing. Refer to → Chapter "Shock Absorber Fork, Removing and Installing".

6 - Nut

- 70 Nm +180º

- Replace after removing

- Tighten either in the curb weight position (refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring") or at the standard vehicle height (refer to → Chapter "Wheel Bearing at Standard Vehicle Height, Lifting Vehicles with Air Suspension").

7 - Bolt

- Replace after removing

8 - Subframe

9 - Bolt

- Replace after removing

10 - Nut

- 70 Nm +180º

- Replace after removing

- Tighten either in the curb weight position (refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring") or at the standard vehicle height (refer to → Chapter "Wheel Bearing at Standard Vehicle Height, Lifting Vehicles with Air Suspension").

11 - Bonded Rubber Bushing

- Replacing. Refer to → Chapter "Guide Link Bonded Rubber Bushing, Removing and Installing".

12 - Guide Link

- Removing and installing. Refer to → Chapter "Guide Link, Removing and Installing".

13 - Nut

- 90 Nm +90º

- Replace after removing

- Tighten either in the curb weight position (refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring") or at the standard vehicle height (refer to → Chapter "Wheel Bearing at Standard Vehicle Height, Lifting Vehicles with Air Suspension").

14 - Wheel Bearing Housing

15 - Nut

- 140 Nm

- Replace after removing

- When reusing the guide link clean the pin threads from the remaining locking compound residue

16 - Bolt

- 40 Nm

- Replace after removing

17 - Nut

- Replace after removing

- 120 Nm

- When reusing the ball joint clean the pin threads from the remaining locking compound residue

18 - Ball Joint

- Removing and installing. Refer to → Chapter "Ball Joint, Removing and Installing".