Audi Q7: Gear Oil, Checking Level

Gear Oil, Checking Level, Front Final Drive

Special tools and workshop equipment required

- Used Oil Collection and Extraction Unit -SMN372500-

- Pressurized Gearbox Oil Filler Kit -VAS6617-

- Protective Eyewear

Procedure

- Gear oil temperature: approximately 20 ºC (68 ºF) (room temperature).

- Move the vehicle onto a 4-column shop hoist or over a work pit so it is completely level.

- Transmission is in "P".

- The parking brake button is pressed to activate the electro-mechanical parking brake.

Note

Note

- General repair instructions. Refer to → Chapter "General Repair Information".

- Guidelines for clean working conditions. Refer to → Chapter "Guidelines for Clean Working Conditions".

- Always maintain the specified transmission fluid level; the transmission is very sensitive to overfilling.

- Replace the plug for the inspection and fill hole.

- Remove the center or rear noise insulation. Refer to → Body Exterior; Rep. Gr.66; Noise Insulation; Noise Insulation, Removing and Installing.

- Place the Used Oil Collection and Extraction Unit -SMN372500- under the transmission.

Note

Note

To catch escaping gear oil, place multiple cloths on the subframe crossbrace.

WARNING

WARNING

Danger of eye injury.

Wear protective eyewear.

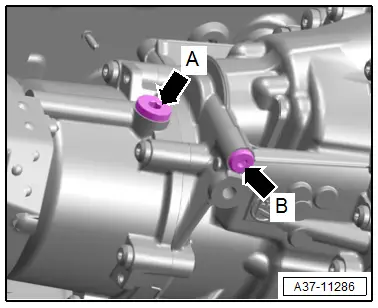

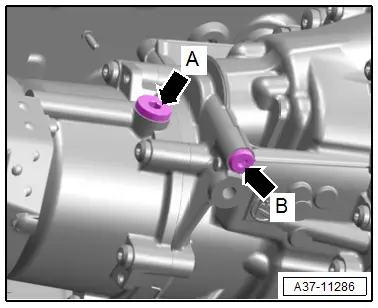

- Remove the fill/check plug -arrow A- from the front final drive.

- Specified value: The oil level is correct when the front final drive is filled to the lower edge of the filler opening.

- Let any excess oil drain.

If the Level Does Not Reach the Bottom of the Oil Fill Hole in the Front Final Drive:

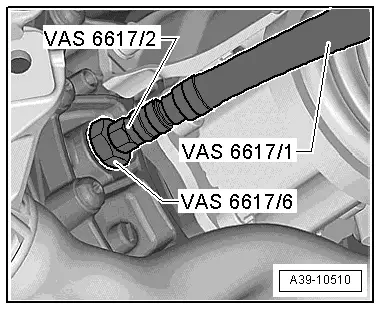

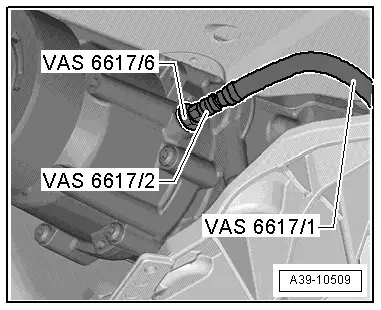

- Install the Pressurized Gearbox Oil Filler - Adapter 6 -VAS6617/6- with the Pressurized Gearbox Oil Filler - Adapter 2 -VAS6617/2- in the inspection and fill hole in the front final drive.

- Connect the Pressurized Gearbox Oil Filler Kit -VAS6617- and fill the front final drive with gear oil.

- Transmission fluid. Refer to the Parts Catalog.

- Remove the Pressurized Gearbox Oil Filler - Adapter 6 -VAS6617/6- from the transmission and let any extra gear oil drain out.

- Tighten the new fill/check plug -arrow A- for the front final drive.

- Remove the cloth from the subframe crossbrace.

Tightening Specifications

- Refer to → Body Exterior; Rep. Gr.66; Noise Insulation; Overview - Noise Insulation.

Gear Oil, Checking Level, Transfer Case

Special tools and workshop equipment required

- Used Oil Collection and Extraction Unit -SMN372500-

- Pressurized Gearbox Oil Filler Kit -VAS6617-

- Protective Eyewear

Procedure

- Gear oil temperature: approximately 20 ºC (68 ºF) (room temperature).

- Move the vehicle onto a 4-column shop hoist or over a work pit so it is completely level.

- Transmission is in "P".

- The parking brake button is pressed to activate the electro-mechanical parking brake.

- The transmission must be still for at least 15 minutes to make sure the oil settles internally.

Note

Note

- General repair instructions. Refer to → Chapter "General Repair Information".

- Guidelines for clean working conditions. Refer to → Chapter "Guidelines for Clean Working Conditions".

- Replace the plug for the inspection and fill hole.

- Place the Used Oil Collection and Extraction Unit -SMN372500- under the transmission.

Note

Note

To catch escaping gear oil place multiple cloths around the tunnel crossmember.

WARNING

WARNING

Danger of eye injury.

Wear protective eyewear.

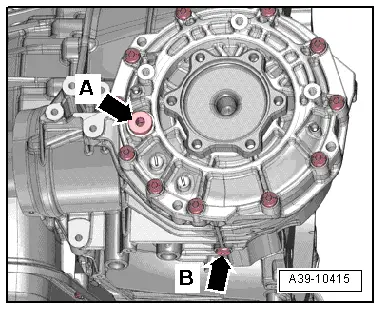

- Remove the fill/check plug -arrow A- from the center differential housing.

- Specified value: The oil level is correct when the transfer case is filled to the lower edge of the filler opening.

- Let any excess oil drain.

If the Level in the Transfer Case Does Not Reach the Lower Edge of the Oil Fill Hole:

- Install the Pressurized Gearbox Oil Filler - Adapter 6 -VAS6617/6- with the Pressurized Gearbox Oil Filler - Adapter 2 -VAS6617/2- in the inspection and fill hole in the transfer case hand-tight.

- Connect the Pressurized Gearbox Oil Filler Kit -VAS6617- and fill the transfer case with gear oil.

- Transmission fluid. Refer to the Parts Catalog.

- Wait five minutes.

Note

Note

- The inside of the transfer case is divided into several oil chambers. The chambers must be filled equally.

- A waiting time of at least five minutes is required so that the internal oil level between the center differential and oil fill space can equalize.

- Remove the Pressurized Gearbox Oil Filler - Adapter 6 -VAS6617/6- from the transmission and let any extra gear oil drain out.

- Tighten the new fill/check plug -arrow A- for the center differential housing.

- Remove the cloth from the tunnel crossmember.