Audi Q7: Overview - Final Drive

Audi Q7 (4M) 2016-2025 Workshop Manual / Drivetrain / Rear Final Drive, Differential / Final Drive / Overview - Final Drive

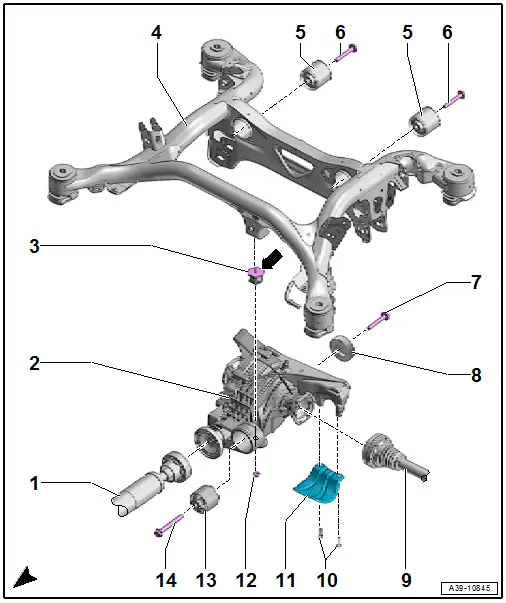

Overview - Rear Final Drive

Rear Final Drive

1 - Driveshaft

- Removing and installing. Refer to → Chapter "Driveshaft, Removing and Installing".

- Removing and installing on the rear final drive. Refer to → Chapter "Drive Shaft, Removing from Rear Final Drive and Installing".

2 - Rear Final Drive

- Refer to → Chapter "Final Drive, Removing and Installing"

3 - Auxiliary Mount

- 20 Nm

- Tightening is only permitted via the upper hex fitting -arrow-.

- Not installed on all versions

4 - Subframe

- Removing and installing. Refer to → Suspension, Wheels, Steering; Rep. Gr.42; Subframe; Overview - Subframe.

5 - Rear Bonded Rubber Bushing

- Removing and installing. Refer to → Suspension, Wheels, Steering; Rep. Gr.42; Subframe; Overview - Subframe.

6 - Bolt

- 90 Nm + 90º

- Always replace.

7 - Bolt

- 55 Nm + 90º

- Always replace.

8 - Vibration Damper

- Not installed on all versions

Installation position:

- The inner protruding collar points toward the final drive

9 - Drive Axle

- Removing and installing. Refer to → Suspension, Wheels, Steering; Rep. Gr.42; Drive Axle; Drive Axle, Removing and Installing.

10 - Bolt

- 23 Nm

11 - Heat Shield

12 - Nut

- 20 Nm

- Not installed on all versions

13 - Front Bonded Rubber Bushing

14 - Bolt

- 130 Nm + 180º

- Always replace.