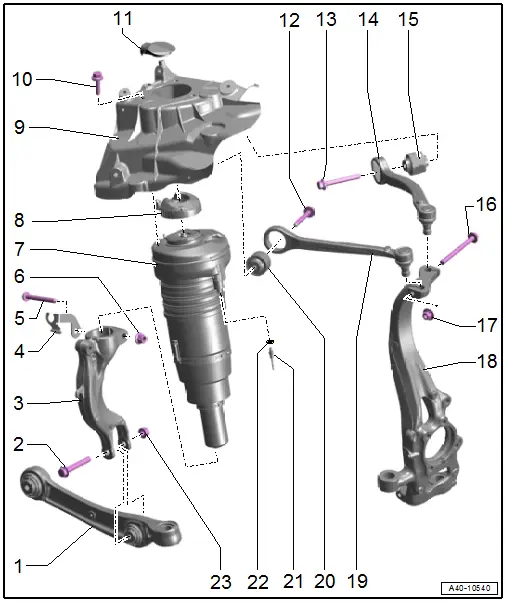

Audi Q7: Overview - Suspension Strut and Upper Control Arm

Overview - Suspension Strut and Upper Control Arm

1 - Control Arm

2 - Bolt

- Replace after removing

3 - Shock Absorber Fork

- Removing and installing. Refer to → Chapter "Shock Absorber Fork, Removing and Installing".

4 - Bracket

- For brake hose

5 - Bolt

- Replace after removing

6 - Nut

- 40 Nm +180º

- Replace after removing

- Tighten either in the curb weight position (refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring") or at the standard vehicle height (refer to → Chapter "Wheel Bearing at Standard Vehicle Height, Lifting Vehicles with Air Suspension").

7 - Suspension Strut

- Shown: for versions with air suspension

- Overview - Suspension Strut Coil Spring. Refer to → Chapter "Overview - Suspension Strut Coil Spring".

- Overview - Air Suspension Strut. Refer to → Chapter "Overview - Air Suspension Strut".

- Installation position. Refer to → Fig. "Installation Position Air Spring Suspension Strut".

8 - Cap

9 - Suspension Strut Tower

10 - Bolt

- Tightening Specifications

- M8x28 bolt with collar: 20 Nm +45º

- M8x32 self-locking bolt with washer: 20 Nm +90º

- Different versions depending on the vehicle. Refer to the Parts Catalog.

- Replace after removing

- Threaded holes for the self-locking bolts must be cleaned, for example, with a thread tap

11 - Cover

- For the connector

- For versions with air suspension

12 - Bolt

- 50 Nm +90º

- Replace after removing

- Tighten either in the curb weight position (refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring") or at the standard vehicle height (refer to → Chapter "Wheel Bearing at Standard Vehicle Height, Lifting Vehicles with Air Suspension").

13 - Bolt

- 50 Nm +90º

- Replace after removing

- Tighten either in the curb weight position (refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring") or at the standard vehicle height (refer to → Chapter "Wheel Bearing at Standard Vehicle Height, Lifting Vehicles with Air Suspension").

14 - Upper Rear Control Arm

- Removing and installing. Refer to → Chapter "Upper Control Arm, Removing and Installing".

15 - Bonded Rubber Bushing

- Replacing. Refer to → Chapter "Upper Control Arm Bearing, Replacing".

16 - Bolt

- Replace after removing

17 - Nut

- 40 Nm

- Replace after removing

18 - Wheel Bearing Housing

19 - Upper Front Control Arm

- Removing and installing. Refer to → Chapter "Upper Control Arm, Removing and Installing".

20 - Bonded Rubber Bushing

- Replacing. Refer to → Chapter "Upper Control Arm Bearing, Replacing".

21 - Air Line

- Do not loosen the residual pressure valve

- Tightening specification. Refer to -item 5-

22 - O-Ring

- If sealing ring is leaking nip open and replace.

23 - Nut

- 40 Nm +180º

- Replace after removing

- Tighten either in the curb weight position (refer to → Chapter "Wheel Bearing in Curb Weight Position, Lifting Vehicles with Coil Spring") or at the standard vehicle height (refer to → Chapter "Wheel Bearing at Standard Vehicle Height, Lifting Vehicles with Air Suspension").

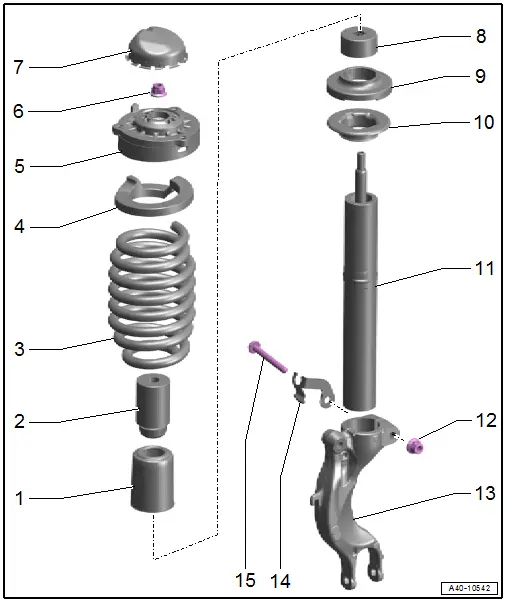

Overview - Suspension Strut Coil Spring

1 - Protective Cover

2 - Stop Buffer

3 - Coil Spring

4 - Spring Support

5 - Strut Mount

- Installation position. Refer to → Fig. "Suspension Strut Coil Spring Installation Position".

6 - Nut

- 50 Nm

- Replace after removing

7 - Cap

- Installation position. Refer to → Fig. "Coil Spring Cap Installation Position".

8 - Protective Cap

9 - Backing Plate

10 - Lower Spring Plate

11 - Shock Absorber

- Because of different shock absorber valve systems, only install new shock absorbers from the same manufacturer on both axles, if possible.

- Removing and installing. Refer to → Chapter "Suspension Strut, Servicing".

12 - Nut

- Tightening specification. Refer to -item 6-

13 - Shock Absorber Fork

- Removing and installing. Refer to → Chapter "Shock Absorber Fork, Removing and Installing".

14 - Bracket

- For brake hose

15 - Bolt

- Replace after removing

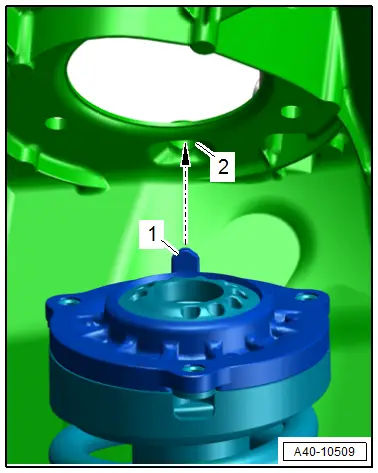

Suspension Strut Coil Spring Installation Position

- The strut mount positioning pin -1- must engage in the hole -2- in the suspension strut tower in direction of -arrow-.

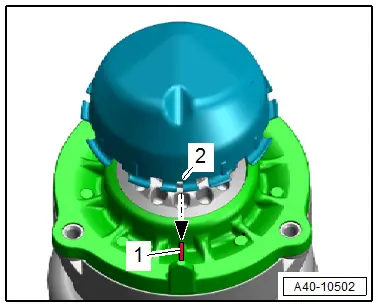

Coil Spring Cap Installation Position

- The opening -2- of the cap must be flush with the strut mount positioning pin -1- in direction of -arrow-.

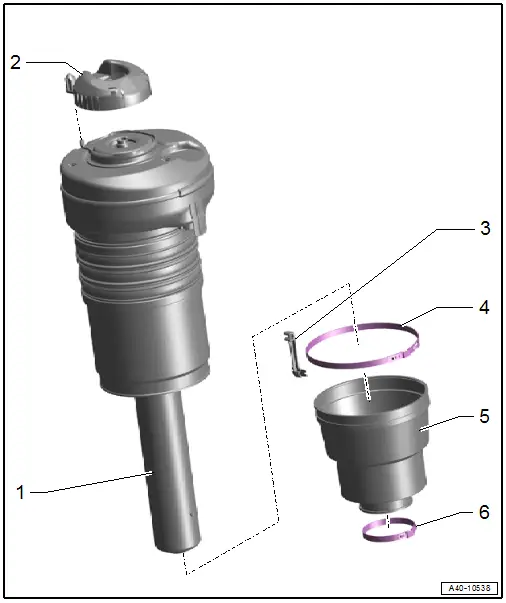

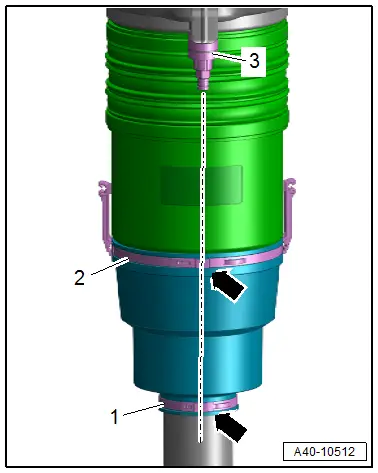

Overview - Air Suspension Strut

1 - Air Spring Strut

- With the Left Front Damping Adjustment Valve -N336-/Right Front Damping Adjustment Valve -N337-

- If faulty replace the complete valve for the air spring damping adjustment

2 - Cap

- Installation position. Refer to → Fig. "Air Spring Cap Installation Position".

3 - Bracket

- For the air line

- Quantity: 2

- Installation position. Refer to → Fig. "Air Line Bracket Installation Position".

4 - Clamp

- Replace after removing

- Installation position. Refer to → Fig. "Clamp Installation Position".

- Tensioning. Refer to → Fig. "Tension the Clamp on the Air Spring.".

5 - Boot

- Must not have any pressure marks; correct any pressure marks by hand.

- Push upward over the collars on the suspension strut housing

- Replacing. Refer to → Chapter "Boot, Replacing".

- Installation position. Refer to → Fig. "Boot Installation Position".

6 - Clamp

- Replace after removing

- Installation position. Refer to → Fig. "Clamp Installation Position".

- Tensioning. Refer to → Fig. "Tension the Clamp on the Air Spring.".

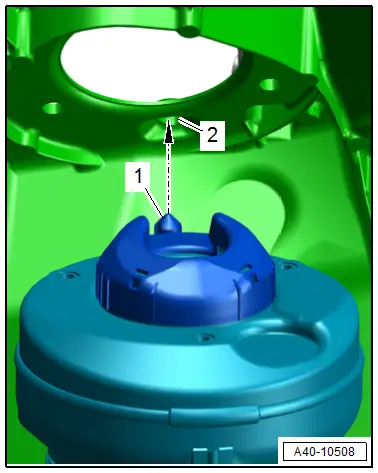

Installation Position Air Spring Suspension Strut

- The cap positioning pin -1- must engage in the hole -2- in the suspension strut tower in direction of -arrow-.

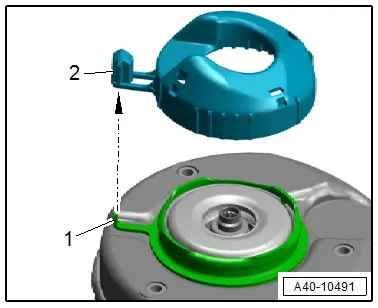

Air Spring Cap Installation Position

- The suspension strut positioning pin -1- must engage in the cap -2- in direction of -arrow-.

- Push in the cap until it engages audibly.

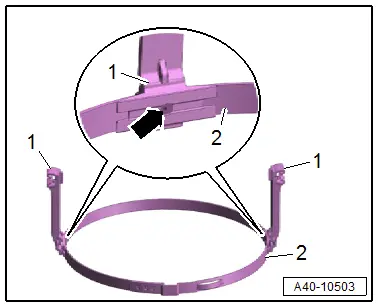

Air Line Bracket Installation Position

- Position the bracket -1- over the pointed protrusion -arrow- on the clamp -2 -as shown.

Clamp Installation Position

- The clamping ears -arrows- of the clamps -1 and 2- must align with the residual pressure valve -3- as shown.

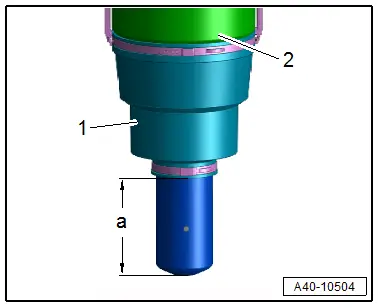

Boot Installation Position

- Push the boot -1- upward over the collars on the suspension strut housing -2-.

- Pay attention to the lower dimension -a-.

- Dimension -a- = 96 mm.

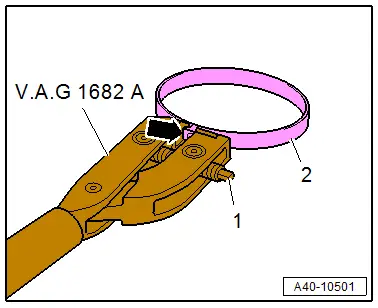

Tension the Clamp on the Air Spring.

- Before tensioning the clamp pay attention to their installation position. Refer to → Fig. "Air Line Bracket Installation Position" and → Fig. "Clamp Installation Position".

- To tension the lower clamp press the front wheels accordingly.

- To tension the upper clamp lift the wheel bearing into the standard vehicle height. Refer to → Chapter "Wheel Bearing at Standard Vehicle Height, Lifting Vehicles with Air Suspension".

- Attach the Clampling Pliers -VAG1682A- as shown. When doing that, make sure the jaws on the pliers are centered -arrow- on the clamping sleeve -2-.

Note

Note

- Make sure the threads on the spindle on the pliers move easily. Lubricate with MoS2 grease, if necessary.

- If difficult to tighten, for example because of dirty threads, the proper clamping force of the clamping sleeve will not be reached even when tightened to the specification.

- Tension the clamp by turning the spindle -1- with the torque wrench, at the same time do not tilt the pliers.

- Tightening specification: 8 Nm.

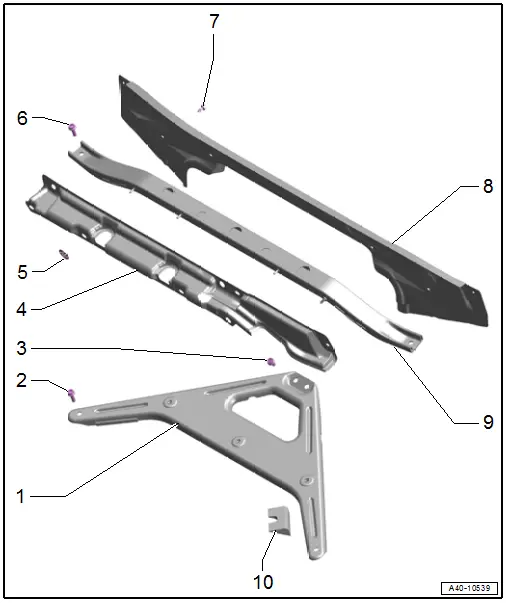

Overview - Tower Brace

1 - Tower Brace

- Removing and installing. Refer to → Chapter "Tower Brace, Removing and Installing".

2 - Bolt

- 25 Nm

3 - Bolt

- 25 Nm

4 - Trim Panel

5 - Lock Washer

6 - Bolt

- 25 Nm

7 - Bolt

- Tightening specification. Refer to → Body Exterior; Rep. Gr.50; Bulkhead; Overview - Bulkhead.

8 - Plenum Chamber End Plate

9 - Additional Reinforcement

- For the tower brace

- Removing and installing. Refer to → Chapter "Tower Brace, Removing and Installing".

10 - Sealing Piece